The problems I alluded to in previous posts are not solved as yet, particularly how to handle free-running cars like box cars in a fashion which is both easy to manage and also prototypical. But here I want to report a couple of things which we have decided to do as “progress” items.

First, we will introduce some of the new waybill designs among the population of existing “mini-bills” as a transitional measure. Second, we will concentrate these bills on the car types and load types which lend themselves to repetitive movement cycles, or simple cycles, or both. Third, we will experiment with a narrow color stripe for load direction (more on this in a moment).

Let me explain what’s meant by (prototypical) repetitive and simple cycles. Cars which are privately owned move at the direction of their owner or lessee, and are not confiscated out of their movement cycles for loading by others. Often a particular car, let’s say a tank car carrying anhydrous ammonia, will not only be restricted to that cargo, but will move repeatedly between a loading point and an unloading point, say from a chemical company to a consumer such as a fertilizer maker. This means a single waybill for that loaded movement, and a corresponding document for empty movement back to the originating point, is a realistic amount of paperwork. (Recall that empty privately-owned tank cars normally moved on regular freight waybills, not on Empty Car Bills.)

I will illustrate my tank car example with a load of anhydrous ammonia from the Olin Mathieson plant in Lake Charles, Louisiana. Here is the inbound load:

The waybill carries the name of T&NO, the originating railroad. When the car is empty, it will move over the reverse route on an SP waybill like this with its former cargo identified for safety (L/C = last contained):

Now let me move on to an example of what I mean by a simple cycle. An on-line producer of cement may ship to a variety of destinations which are also on line. The cars would likely be railroad-owned and would of course be restricted to cement service; they would very probably also cycle as empties back to that same cement producer. That means that the car can move with a single waybill, which carries the name of railroad in question, and “short bills” can be used to vary the destinations (I showed examples of “short bills” in the previous post on this topic, at: http://modelingthesp.blogspot.com/2011/08/waybills-10.html).

An example might be like the following, using an actual on-line producer on the SP. First, the “full size” bill, which I also showed in the “Waybills-9” post:

This is an off-layout destination for McGee’s layout, and its destination during operation would be in Weed staging. Here is a “short bill” which can overlay the bottom part of the bill just shown:

This is also off-layout but the car’s destination now would be Klamath Falls staging, the other “eastward” destination. The Empty Car Bill for this car was also shown previously, in “Waybills-9,” and can be viewed at: http://modelingthesp.blogspot.com/2011/07/waybills-9.html. These three bills, then, can reside in a single sleeve and create reasonable car movements. If the variety seems insufficient, more “short bills” can be added. The goal would be to maintain the car movements as entirely within the SP, thus validating the waybill railroad name at the top of the full-size waybill.

I mentioned use of color stripes as helpful guides to switchmen, regarding routing of cars. The prototype, of course, has no such stripe, nor does it have other codes of that type. Otis now uses a mini-bill which is striped and also labeled for the direction of the car movement, thus:

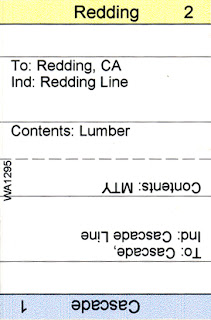

To replace this, we are going to experiment with a different stripe, also yellow to indicate movement to Redding staging. (We know from experience that visiting crews may hardly know whether Oregon is north or south of California, let alone where particular western cities are located. You may insert here the rant of your choice about modern education in geography.) Here is a lumber load waybill, which would replace the one shown above:

If crews seem to need stripes or other codes as “training wheels,” this can be an interim measure. If the need seems to be ongoing, they can be retained. But whether a stripe is retained or not, it should be evident in any case that there is a considerable increase in prototypical appearance from the mini-bill to the new bill, not to mention far more information.

As I said at the outset of this post, there are other experiments in progress, including ways of handling free-running cars like box cars. More on those later.

Tony Thompson

How do you create and print your waybills Tony? One advantage of the (unrealistic) mini-bill is that the information can be created with a spreadsheet, and then printed directly on a sheet of paper that can be cut/folded into many waybills. I prefer your more realistic waybills but if I had to create hundreds of them... can it be automated?

ReplyDeleteTim, I showed the basic process in my post called Waybills-4, back on February 16 of this year (I'd give a link but the "comment" process does not appear able to create links).

ReplyDeleteYou are right that this system is NOT automated. I have played with Excel (as have others) and so far, I don't see that it's possible to do all the things I do with my waybills. I do set them up to be printed, nine to a sheet for the "car sleeve" ones I use on my own layout, ten to a sheet for the ones for Otis McGee's layout.

I agree that making REALLY a lot of waybills is daunting. But most of the work is researching all the information, and you have to do that for ANY method of creating the actual bills. Filling out and printing them up is a lesser part of the total work, at least for me.

If you have suggestions on how to automate the process, I would love to hear about it.

Tony Thompson