In the previous post, I described two of the layouts on which our California contingent operated in the La Crosse, Wisconsin area during our week-long trip to Wisconsin and the Twin Cities. I don’t mean for these posts to be “diary-like,” only to provide information about a few layouts and to thank again the outstanding hospitality of everyone we met on these excursions. That first post is here: https://modelingthesp.blogspot.com/2021/10/an-out-of-town-operating-trip.html .

Our California group was Seth Neumann, Jim Radkey and Ed Slintak, along with me, from the Bay Area, and Al Daumann from Southern California. All of us, like all our hosts on the trip, were fully vaccinated, a factor in these uncertain times.

The morning of the second day we operated at Steve Brudlos’s superb Milwaukee Road River Subdivision, set in the transition era: a very large layout, and beautifully scenicked. I will just show a few of the many photos I took there. This view is at the town of Wabasha, with Nancy Stearns switching the yard (we later visited the fine CB&Q layout under construction by Nancy and her husband Scott).

The overall effect in every area was very well done, but to me more impressive was the level of detail in every scene. Here is a road crossing in the town of Winona, using a mirror so that the road disappearing into the trees isn’t heading into a black hole. But notice all the other details: lampposts, sidewalks and curbs, and the nice treatment of the asphalt road.

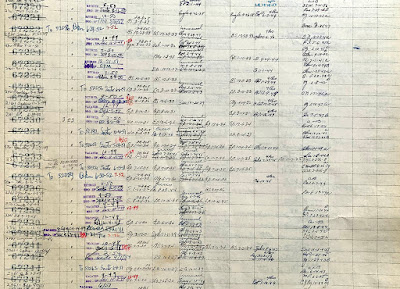

My assignment here was switching the town of Winona, and a semi-schematic map helped greatly. You can readily see the complexity of trackwork and can probably imagine the corresponding complexity of switching needed. It was great fun! and of course a delight in the midst of such excellent scenery work.

In the afternoon we operated on an even bigger layout, Ron Copher’s Lake Erie and Southern. The size was just overwhelming. Below I show one of the long aisles, double-deck on both sides. I did have one road job, and it was really enjoyable to run through all this territory.

My main assignment here was as the engineer of one of the two yard switchers. I had plenty of work to do, which was fun, and you can see from this photo that I could hardly see to the other end of the yard. It often felt like I was operating alone, though in fact the yardmaster directed the work of both yard switchers. Incidentally, that’s Iowa’s Doug Harding at right.

This wrapped up our time in Wisconsin, and it was on to the Twin Cities for the remainder of our trip.

As was the case for the other La Crosse-area layouts, we were very impressed with the quality we saw on Tuesday, and cannot give too high a recommendation for the biennial RiverRail event that these folks host. If you get a chance to attend a RiverRail, don’t fail to go!

Tony Thompson