I think most modelers recognize that the short cylinders on top of tank car domes are safety valves. They are a spring-loaded valve that can be set to the desired release pressure (for example, 35 pounds per square inch for a garden-variety ICC 103 tank car). The purpose of course is to prevent excessive pressure from developing inside a tank car. As I showed in my tank car article in the Model Railroad Hobbyist issue for February 2016 (you can view or download any issue of MRH, any time, for free at their website, www.mrhmag.com ), safety valves can be mounted on top of the dome or on an elbow pipe at the side of the dome, but the interior parts of the valve are identical.

What modelers are usually less familiar with are safety vents. There are several kinds of these, and they are primarily used for tank car cargoes that do not give off flammable vapors nor are otherwise toxic or dangerous. Such cargoes include vegetable oil, wine, molasses, glycerin, vinegar, and so on. (Vents were also approved for some corrosive cargoes.) These vents have a distinctive appearance, and are readily perceived as different from safety valves. They too could be mounted on the dome top or side. Here are a couple of examples.

These are details of photos in the Richard Hendrickson collection. Both cars shown happen to be cars in wine service.

The requirement for expansion capacity, which was the purpose of the dome, was that the dome size had to be at least 2 percent of the tank volume. It is worth noting that, as with safety valves, the side mounting reduced the dome

volume complying with the 2 percent rule, because only the volume below

the side mount could be counted toward the 2 percent. After about 1925, new tank cars generally had their safety valves or vents, whichever was used, mounted on the dome top. But older car conversions or upgrades sometimes received side-mount vents.

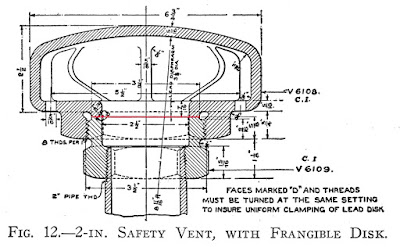

The standard design of these vents, with two-inch inside diameter, is shown in the drawing below (from the 1919 Car Builders Cyclopedia). The key component is indicated in the center, a lead metal diaphragm or disk, about 1/16-inch thick, which is prepared so as to have a rupture pressure of not more than 30 pounds per square inch. The disk is highlighted in red (you may click to enlarge). Obviously if the disk ruptures, the vent must be disassembled to replace it.

This safety vent is the working part of the vents shown in the prototype photos above.

For modeling use, these vents, in both top-mount and side-mount forms, are now available from Owl Mountain Models. (See their parts page at : http://www.owlmtmodels.com/detail_parts/detail_parts.html#Vents .) Here is a view of the top-mount vents, part no. 1004, from the Owl Mountain website:

The elbow or side-mount version is very nice, with an actual elbow rendered on the mounting pipe. Here is a photo of the elbow-mount vent, part no. 1003:

As mentioned in the short essay contained in my “Handout on Wine Tank Cars.” any non-regulatory commodity such as wine could be carried in tank cars with these vents, though a car with standard spring-loaded safety valves could certainly be used equally well. Thus photos of wine tank cars show many examples of cars having conventional safety valves, though most do have frangible-disc safety vents. (You can find that handout at this link: http://modelingthesp.blogspot.com/2017/01/handout-for-wine-tank-cars.html .)

These frangible-disk vents are not for most tank cars. In fact, any tank car equipped with them was recommended to be labeled, “not for inflammable liquids.” But for edible oils, wine, and other cargoes without significant vapor pressure of flammable vapors, these vents were fine. They were not only cheaper as first cost, but did not have to be periodically tested as did safety valves. And on the modeling side, they are essential for modeling some kinds of tank cars.

Tony Thompson

Good post.

ReplyDelete