In my previous post on electrical matters (which you can see at: http://modelingthesp.blogspot.com/2012/09/electrical-wars-part-2.html ), I mentioned that I like to use ground throws (or hand throws) for turnouts wherever I can. But which kind of throw to use is an interesting issue.

Like many modelers in HO scale, I have long used the Caboose Industries no. 202S ground throw. It is easy to install and is mechanically reliable. Electrically, however, it is less than ideal, as it does not exert much pressure between the points and the stock rails, and electrical contact may be imperiled if the turnout is power-routing. And appearance-wise, it is really a cover-your-eyes item, as it is too large even for O scale. When I take layout photos, I have often temporarily placed small pieces of HO shrubbery to conceal these monster ground throws.

Here is just one model photo with an unconcealed Caboose Industries 202S to illustrate what I’m talking about.

Hard to imagine the HO scale man operating that massive ground throw, which is nearly waist-high.

Caboose Industries do make a tall switch stand, which is much closer to scale, and I have had one in service for quite a few years with no mechanical problems. But electrically it seems to be of a piece with the ground throw.

I should mention that Caboose Industries has also produced a ground throw with electrical contacts incorporated, model 119R, which sounds like a good idea. But it is tricky to assemble, and is not, repeat not, durable in use. After trying a couple of these and experiencing early failures, I abandoned the idea and ripped out the ones I had installed.

One solution to the electrical weakness of the Caboose Industries devices is to add auxiliary contacts somewhere. The traditional vertical wire from the throw bar can be used to operate contacts underneath the layout, and if horizontal space is available, a similar process can be created at ground level. Here is the west switch of Shumala, using a ground throw which throws both the switch points and also a set of contacts to power the frog. The contacts are salvaged from a twin-coil switch machine.

In operation, this is concealed inside a section building, as seen in this view.

But these fixes, effective as they are electrically, do not make any improvements in the appearance of the ground throw. And they do require some fiddly placement of the contacts, and occasional adjustment of same, to get effective operation.

What else can one do? Another hand-thrown switch stand I tried years ago is the Star stand made by ST&LO of Flagstaff, Arizona. This has electrical contacts under its base, so is meant to do, and does do, that part of the job without having to use any auxiliary parts. I was worried about its durability, but it is cast brass and is in fact quite sturdy, and not excessively oversize. My only criticism would be that it only rotates about 45 degrees when thrown, so that the target cannot prototypically indicate position of the points, but that’s a minor problem.

The underneath part with the electrical contacts required a hole 0.5 inches deep and 0.75 inches in diameter. The remainder of the instructions is shown on this part of the packaging.

Here is a photo of one of these stands, installed at Ballard on my layout. It is operated by moving the lever, just like the prototype. I wish I could get more of these. I have heard rumors that you can still find them, but I have not been able to do so. This item was reviewed in the Narrow Gauge & Short Line Gazette way back in July/August of 1987 (25 years ago!), so my hopes are not high.

This switch stand is somewhat oversize too, but at least does not dwarf an HO scale figure. The shaft is too tall and I should shorten it to be more realistic.

One solution to these problems is to use slide switches, either remotely operated by a mechanical rod, or on the layout surface to be hand-thrown, thus taking care of both the motion of switch points and electrical contact at the same time. This definitely works. I have done this under the layout, but never on top of the layout. I continue to need a way to hand-throw accessible switches.

A new solution has appeared on the market recently for the ground throw problem. It is produced by Bitter Creek Models. A good summary of its background was published in a review by John R. Signor (in The Warbonnet, magazine of the Santa Fe Railway Historical & Modeling Society, Volume 18, No. 3, Third Quarter 2012, page 46). I reproduce it here with John’s permission. You can click on this to enlarge it if you wish.

I purchased some of these ground throws to try, and can confirm what John says: the positive latching, and the spring-loaded overthrow, do provide dependable electrical contact, while being far smaller than the Caboose Industries product. Here is a view of one in place, not yet painted a more “dirt-like” color:

Note the adjoining Caboose Industries throw, which stands far taller. I will probably repaint the red lever end to a more innocuous color. John has done the same, as you can see in his own installation, pictured at the right in the review above.

I am happy with this Bitter Creek device and am steadily replacing my Caboose Industries ground throws. If you’d like to try them, you can purchase the B-4001 Manual Ground Throw via this link: www.bittercreekmodels.com . They are $9.95 per pair, plus shipping. I think they are a better solution.

Tony Thompson

Sunday, September 30, 2012

Friday, September 28, 2012

A new depot for Shumala

Shumala is the junction on my layout between Southern Pacific’s Coast Line and the SP’s (imaginary) Santa Rosalia branch. I discussed this fictional branch line idea as the core concept in my current layout, in an earlier post about layout locale, at: http://modelingthesp.blogspot.com/2011/01/layout-design-locale.html . On my old layout in Pittsburgh, PA, this town was called Jalama (which is a real place on the SP Coast Line). I presented an overview of the old layout, and a track plan of this part of the layout, in a prior post: http://modelingthesp.blogspot.com/2012/03/survival-from-my-old-layout.html .

On the old layout, Jalama was a junction with the Coast Line main, but the junction was with the imaginary short line, Lompoc & Cuyama. Accordingly, as the short line was supposed to have arrived later, the L&C had to build and man the tower at the interchange, in accord with normal railroad arrangements. I didn’t have much space for a tower, so I chose to build a classic kit from Campbell Scale Models, called Kiowa Junction, which incorporated a small depot as part of the tower structure. I painted it in L&C depot colors, since supposedly it was an L&C structure.

Here is a photo of that depot, at left, with the L&C’s only diesel locomotive on the track behind it, just departing inland. (And note one of the L&C standard cabooses, based on Yosemite Valley no. 15, as described previously: http://modelingthesp.blogspot.com/2012/08/whimsy.html .)

And here’s a view from the other end. That’s the tunnel to Ballard in the background.

This depot-tower was fine in that layout concept, but with the change to the junction being a pretty small branch line of the SP, there was far too little traffic to justify having a tower. Moreover, because the Campbell Kiowa Junction kit was based on a Santa Fe structure at Ottawa Junction, Kansas (see Paul Larson’s construction article in Model Railroader, August 1952), it is not a very good choice for an SP-built depot. Though I’ve always liked the Ottawa Junction structure and the model I built of it, it had to be replaced with an SP depot.

One of the attractions of creating a believable branch line of any railroad is the depots, because they are among the things that tell you at a glance which railroad it is. So you need to have standard or at least recognizable depots. Southern Pacific modelers in HO scale are blessed, in that kits exist for the two depot designs that were built in very large numbers, designated as CS 22 and CS 23 (American Model Builders, kits 134 and 150, respectively). But for my branch line junction at Shumala, the AMB kits aren’t usable because the space available is too small, less than half the size of a CS 22 depot.

On the old layout, Jalama was a junction with the Coast Line main, but the junction was with the imaginary short line, Lompoc & Cuyama. Accordingly, as the short line was supposed to have arrived later, the L&C had to build and man the tower at the interchange, in accord with normal railroad arrangements. I didn’t have much space for a tower, so I chose to build a classic kit from Campbell Scale Models, called Kiowa Junction, which incorporated a small depot as part of the tower structure. I painted it in L&C depot colors, since supposedly it was an L&C structure.

Here is a photo of that depot, at left, with the L&C’s only diesel locomotive on the track behind it, just departing inland. (And note one of the L&C standard cabooses, based on Yosemite Valley no. 15, as described previously: http://modelingthesp.blogspot.com/2012/08/whimsy.html .)

And here’s a view from the other end. That’s the tunnel to Ballard in the background.

This depot-tower was fine in that layout concept, but with the change to the junction being a pretty small branch line of the SP, there was far too little traffic to justify having a tower. Moreover, because the Campbell Kiowa Junction kit was based on a Santa Fe structure at Ottawa Junction, Kansas (see Paul Larson’s construction article in Model Railroader, August 1952), it is not a very good choice for an SP-built depot. Though I’ve always liked the Ottawa Junction structure and the model I built of it, it had to be replaced with an SP depot.

One of the attractions of creating a believable branch line of any railroad is the depots, because they are among the things that tell you at a glance which railroad it is. So you need to have standard or at least recognizable depots. Southern Pacific modelers in HO scale are blessed, in that kits exist for the two depot designs that were built in very large numbers, designated as CS 22 and CS 23 (American Model Builders, kits 134 and 150, respectively). But for my branch line junction at Shumala, the AMB kits aren’t usable because the space available is too small, less than half the size of a CS 22 depot.

By the way, if you would like to learn more about SP standard depots, the best source at present is Henry E. Bender’s pair of articles, entitled “Southern Pacific Lines Standard Design Depots,” Parts 1 and 2, in the SP Historical & Technical Society magazine, Trainline, issues 57 (Fall 1998, pages 11–26) and 58 (Winter 1998, pages 27–33). I say “at present” because although Henry’s book-length expansion of this material is en route to publication by Signature Press, it’s too early to estimate a release date.

For extensive views of depots throughout the Pacific Lines of the SP, there was published a three-book series by the SP Historical & Technical Society, compiled by John R. Signor and entitled Pacific Lines Stations, Volumes 1 through 3, in 1997, 1998 and 1999, respectively. Though unfortunately out of print, they can often be obtained from used book dealers. I used the many photos of depots in these books to determine the most common features that I should incorporate into my Shumala depot.

Needing, as I said, a smaller depot for Shumala, I searched for one of SP’s smaller depots, standard or close to standard, that I could build. I settled on the depot originally designed for Sylmar, California, which is a couple of miles west of San Fernando in Southern California. Plans for this depot can be found in the book, Southern Pacific Lines Common Standard Plans, Volume 5, Steam Age Equipment Company, Dunsmuir, CA 1997, pages 18 and 19.

I include two parts of the drawing below as a relatively low resolution jpeg, but both large sheets are also available as a PDF on Google Docs (at this link: https://docs.google.com/file/d/0Bz_ctrHrDz4wNFFiTDhkOWxLQVE/edit ). You can click on it to enlarge the image. At original size, as on the PDF, the drawing is to HO scale, facilitating the sizing of details.

Although quite narrow at 12 by 56 feet, the Sylmar plan could be widened to fit my space, which was 17 by 49 feet. Many SP standard depots were 20 feet wide, so the wider look is appropriate. I would also have to shorten the freight room by seven scale feet, but one of the primary variations among different versions of SP’s standard depot designs was the size of the freight rooms.

Here is how I would summarize the characteristics of this depot, from examination of the plans. The building had a small waiting room, about 12 feet long at one end, adjoining an office about 9 feet long, which also had a rectangular operator’s bay. This type of bay is quite typical of SP depots. The balance of the structure is the freight room, which I would shorten. I would also have to modify the full freight platform as shown on the drawing, since I don’t have enough space, but I could rearrange it somewhat, to match other SP depot designs.

At this point, knowing the features of SP standard design and the changes I would have to make to fit my space, I could proceed to choosing model materials and a construction process. Those steps have been written up for my forthcoming column, which will appear in the November 2012 issue of Model Railroad Hobbyist, on line. It’s always a free download from the MRH site at http://model-railroad-hobbyist.com/ , and should be available on or soon after November 1.

At this point, knowing the features of SP standard design and the changes I would have to make to fit my space, I could proceed to choosing model materials and a construction process. Those steps have been written up for my forthcoming column, which will appear in the November 2012 issue of Model Railroad Hobbyist, on line. It’s always a free download from the MRH site at http://model-railroad-hobbyist.com/ , and should be available on or soon after November 1.

Tony Thompson

Wednesday, September 26, 2012

Visiting a rail museum in Budapest

My wife and I recently returned from a short trip to Prague, Bratislava and Budapest, and among the activities always interesting to watch on such a trip is railroading. We were pretty busy seeing the standard sights, and there wasn’t a great deal of time for trains, but in Budapest I had a little free time and took the opportunity to go off to the Transport Museum in City Park there. It is really an impressive museum.

Here are two views of the 4-8-0 locomotive preserved outside the building.

Posed in front of the engine in the second view is Geoff Rezek, to whom I am indebted for these museum views, as he had his camera and I didn’t have mine.

Inside, numerous original locomotives were preserved, along with many really excellent 1:5 models of a wide range of other engines. This view shows a small fraction of the collection, but gives an idea of the arrangement.

While at the museum, I found a current copy of the local model magazine, which I show below. Its title means “Train and Model.”

I enjoyed the interior of the magazine too, though I don’t read Magyar (Hungarian). The model and prototype photos are self-explanatory. One thing I especially liked was this advertisement:

The headline means, approximately, “you’d like to go here,” and I always enjoy (restrained) humor in modeling.

The company, Miha Modell, is a German firm making Code 250 rail in both steel and nickel-silver, as well as tie strip and wheelsets for large-scale modeling. Their web site is: http://www.miha-modell.de/ and the considerable scope of their products is evident there.

Here are two views of the 4-8-0 locomotive preserved outside the building.

Posed in front of the engine in the second view is Geoff Rezek, to whom I am indebted for these museum views, as he had his camera and I didn’t have mine.

Inside, numerous original locomotives were preserved, along with many really excellent 1:5 models of a wide range of other engines. This view shows a small fraction of the collection, but gives an idea of the arrangement.

While at the museum, I found a current copy of the local model magazine, which I show below. Its title means “Train and Model.”

I enjoyed the interior of the magazine too, though I don’t read Magyar (Hungarian). The model and prototype photos are self-explanatory. One thing I especially liked was this advertisement:

The headline means, approximately, “you’d like to go here,” and I always enjoy (restrained) humor in modeling.

The company, Miha Modell, is a German firm making Code 250 rail in both steel and nickel-silver, as well as tie strip and wheelsets for large-scale modeling. Their web site is: http://www.miha-modell.de/ and the considerable scope of their products is evident there.

I describe all these matters not as a tribute to a specific museum, though it is a good one, but to illustrate that taking the opportunity to explore whatever railroad-related sights are handy, can often be interesting and fun.

Tony Thompson

Monday, September 24, 2012

Electrical wars, Part 2

I didn’t mean to be obscure about the electrical changes and upgrades I was describing in my first post of this topic (here is a link to that previous post: http://modelingthesp.blogspot.com/2012/09/electrical-wars.html ). But some responses I have received indicated that some confusion was created. There are two points to clarify.

First, it did not seem to be clear where the gaps were located that I was replacing, nor (to others) where they were when I was done. It is easily shown in a simple diagram, using the conventional arrow heads and tails for feeders on the two rails, and black rectangles for gaps. I usually place my feeders at about the same location, so the arrowheads and tails are literally at the same place. Here is the original arrangement on almost all my sidings.

This does not present a problem if the siding is a few carlengths long, but when it is, say, six feet or more, it can become tedious to have to go all the way to the other end to power the intervening track.

The change is to place gaps at the ends of sidings and feed the middle, though this does require more gaps and more feeders. As I stated in the previous post, it now looks to me like it was a false economy to have saved this minor amount of ocmplexity. Here is the new arrangement.

Operation with the new gaps and feeders is already improved.

The other point has to do with powering frogs. There are lots of approaches to this problem, with or without DCC, and mine has always been to use hand throws for all turnouts which are reasonably accessible, and rely on point contact with stock rails to transmit power to the frog, which usually works pretty well with my power-routing turnouts. The sides of stock rails and points do need to be cleaned occasionally, and this is the one place I have found that “contact fluid” (however constituted) is helpful over the long term.

For many years, I have operated my hand-thrown turnouts with the Caboose Hobbies manual ground throw. Powered turnouts, of course, can be arranged with auxiliary contacts on the switch machine to ensure good power transfer.

But the familiar Caboose Hobbies ground throw is only an adequate way of handling turnouts. It does not provide much pressure against the stock rail, and of course is immensely oversize and out of scale. It is even too big for O scale, if you compare it to prototype photos of the kind of ground throw being modeled. I have experimented with a number of alternatives, and will discuss those in a future post.

Tony Thompson

First, it did not seem to be clear where the gaps were located that I was replacing, nor (to others) where they were when I was done. It is easily shown in a simple diagram, using the conventional arrow heads and tails for feeders on the two rails, and black rectangles for gaps. I usually place my feeders at about the same location, so the arrowheads and tails are literally at the same place. Here is the original arrangement on almost all my sidings.

This does not present a problem if the siding is a few carlengths long, but when it is, say, six feet or more, it can become tedious to have to go all the way to the other end to power the intervening track.

The change is to place gaps at the ends of sidings and feed the middle, though this does require more gaps and more feeders. As I stated in the previous post, it now looks to me like it was a false economy to have saved this minor amount of ocmplexity. Here is the new arrangement.

Operation with the new gaps and feeders is already improved.

The other point has to do with powering frogs. There are lots of approaches to this problem, with or without DCC, and mine has always been to use hand throws for all turnouts which are reasonably accessible, and rely on point contact with stock rails to transmit power to the frog, which usually works pretty well with my power-routing turnouts. The sides of stock rails and points do need to be cleaned occasionally, and this is the one place I have found that “contact fluid” (however constituted) is helpful over the long term.

For many years, I have operated my hand-thrown turnouts with the Caboose Hobbies manual ground throw. Powered turnouts, of course, can be arranged with auxiliary contacts on the switch machine to ensure good power transfer.

But the familiar Caboose Hobbies ground throw is only an adequate way of handling turnouts. It does not provide much pressure against the stock rail, and of course is immensely oversize and out of scale. It is even too big for O scale, if you compare it to prototype photos of the kind of ground throw being modeled. I have experimented with a number of alternatives, and will discuss those in a future post.

Tony Thompson

Wednesday, September 19, 2012

Class A-50-4 auto cars -- new update

In an earlier post, I used the Southern Pacific Class A-50-4 automobile cars as an example to illustrate the information which exists in the SP Car Ledgers. I applied that information to determining how many cars of this class survived into 1953 (which was a question I’d been asked) and whether they had AB brakes applied. I also showed prototype photos. You can view that post at: http://modelingthesp.blogspot.com/2012/05/sp-car-ledgers-and-class-50-4-auto-cars.html .

Since that post, further questions have arisen about the A-50-4 cars, in particular whether they kept their original Vulcan trucks or received new U-section cast steel AAR trucks, a change made on many older SP freight cars. Again, the Car Ledger contains this information, showing the date and place of such a replacement, if it occurred. For the cars listed in the previous post as late survivors, here are the truck data.

I took him up on it, knowing that he is a fine craftsman, although since I much enjoy applying decal lettering and then weathering my freight cars, I asked him to build and paint it but not to do any lettering. The car did have AB brakes and Vulcan trucks in 1953, which is how Pierre built it.

Presently the completed car arrived, beautiful as expected, and I applied the lettering and weathering. Here is a view of the completed car. It would no longer have been in automobile service by 1953, but retains that lettering because at that time the AAR still defined double-door cars as automobile cars.

I really like this car as part of my SP freight car fleet, with its funky steep diagonal brace at the right side of the door, created when the door opening was enlarged (see the prototype photo in the previous post, cited in the first paragraph of this post). It is now at work on my layout, hauling lumber (a common SP use for double-door cars no longer suitable for automobiles).

Tony Thompson

Since that post, further questions have arisen about the A-50-4 cars, in particular whether they kept their original Vulcan trucks or received new U-section cast steel AAR trucks, a change made on many older SP freight cars. Again, the Car Ledger contains this information, showing the date and place of such a replacement, if it occurred. For the cars listed in the previous post as late survivors, here are the truck data.

For each car surviving into 1953, I have indicated whether trucks were replaced, and the date of replacement. You will see that of the 13 cars in this list, only five got new trucks before scrapping.

First, the batch of 250 cars built for SP in 1921, numbers 63080–63328:

63084, trucks replaced 10-48

63094, trucks not replaced

63140, replaced 2-49

63180, trucks not replaced

63197, replaced 6-49

63297, trucks not replaced

63325, trucks not replaced

63084, trucks replaced 10-48

63094, trucks not replaced

63140, replaced 2-49

63180, trucks not replaced

63197, replaced 6-49

63246, replaced 2-53

63261 trucks not replaced63297, trucks not replaced

63325, trucks not replaced

Second, the 150-car batch built for T&NO in 1921 and acquired by Pacific Lines in 1936, SP 63600–63746:

63666, trucks not replaced

63666, trucks not replaced

63699, trucks not replaced

63707, replaced 11-53 (scrapped summer 1954)

63707, replaced 11-53 (scrapped summer 1954)

63727, trucks not replaced

This list probably isn’t exhaustive but it should provide truck information for nearly all or all of the survivors past 1-53. For modelers, obviously, the date one models will determine what kind of trucks should be under the model.

This SP car class is of particular interest to me, because an HO scale kit for it exists. The kit was developed by Speedwitch Media for the SP Historical & Technical Society convention in 2005, and like all Speedwitch kits, it is a beautiful model. It represents the cars late in their lives, with the enlarged side door opening which was shown in a photograph in the prior A-50-4 post (cited above). I had this kit on the shelf, until I had an offer from Pierre Oliver of Elgin Car Shops (visit http://www.elgincarshops.com/ ), who was about to build another A-50-4 for a client, to build my kit as well.I took him up on it, knowing that he is a fine craftsman, although since I much enjoy applying decal lettering and then weathering my freight cars, I asked him to build and paint it but not to do any lettering. The car did have AB brakes and Vulcan trucks in 1953, which is how Pierre built it.

Presently the completed car arrived, beautiful as expected, and I applied the lettering and weathering. Here is a view of the completed car. It would no longer have been in automobile service by 1953, but retains that lettering because at that time the AAR still defined double-door cars as automobile cars.

I really like this car as part of my SP freight car fleet, with its funky steep diagonal brace at the right side of the door, created when the door opening was enlarged (see the prototype photo in the previous post, cited in the first paragraph of this post). It is now at work on my layout, hauling lumber (a common SP use for double-door cars no longer suitable for automobiles).

Tony Thompson

Friday, September 14, 2012

PFE operations -- from Pete Holst

As part of the research for the PFE book (Pacific Fruit Express, 2nd edition, A.W. Thompson, R.J. Church, B.H. Jones, Signature Press, 2000), I interviewed a number of PFE retirees. The interviews were taped and later transcribed. Some of the insights into how things were done were invaluable.

In this post I present a small part of two long interviews with A.L. “Pete” Holst, who worked his whole career for PFE, starting in 1917. He retired as Assistant General Manager for Car Service at San Francisco. My first interview was at hs home in San Mateo, on January 30, 1986. I will pick up somewhere around the middle, when we talked details of operations. My comments are denoted as “Q” for questioner, Pete’s answers as “A.”

A. I had a lot of arguments with some of the managers, after I was in Los Angeles down there, during the World War down there, you know, we had a lot of shortages of ice everywhere. I finally sat down with the old guy that ran the Santa Fe’s Refrigeration Department, and we pulled a lot of stuff, traded ice, switched ice, and everything else. I’d give him ice if he was short, give him ice from Colton, and he’d give me ice from Bakersfield. We saved a hell of a lot of cross-hauling of ice.

Q. Was that plant in Bakersfield theirs?

A. Well, they had a plant in Bakersfield, and we had a plant, but they had a bigger plant than we did. They had a big plant at San Bernardino, that’s where their big plant was. When I needed ice in Imperial Valley, and I ran out of the other sources, why, I traded ice up the valley with the Santa Fe. We saved a lot of cross-hauling. For years we’d been shipping ice right by their ice plants, and one thing and another. So we got a break with old John Daly, and he was glad to get it.

Q. I suppose the Santa Fe reefers didn’t show up on SP tracks, for SP shippers to use. Or did you use them if you needed the empties?

A. No, no, we didn’t trade with the Santa Fe on cars. They were a little too jealous for that. We wouldn’t let a Santa Fe car be loaded on our line either. We switched ’em back and forth down there, of course, and if they were unloaded on the SP we turned ’em back, and they would, too. If PFE’s cars were unloaded on the Santa Fe, they’d give ’em back to us. We could always use ‘em.

Q. I’ve read that three sizes of ice were used on the deck, that were chunk, coarse, and crushed, I think. Is that right?

A. Yeah. You always had crushed ice for the meat cars, they generally took small pieces, you know, and you iced the frozen food cars with more or less smaller chunks.

Q. How big would those be?

A. Oh, they’d be 25, 30, 50 pounds. You chopped it up a little more because you were putting 30 per cent salt in ’em, see.

Q. Then you put the salt in, for the others?

A. No, you dump the salt in as you put the ice in. After you got it about half full, then you start pouring salt in.

Q. No, I meant for regular icing. Did they put in the whole cake, or whatever would fit in the hatch?

A. No, you’re never supposed to put that in. It’s supposed to be a quarter of a 300-pound cake. You cut it in half this long way, and then this way. We had a lot of trouble, you see, with the cars whenever they used to take over a half a tank of ice. The Claim Department, the claim clerks of the shippers, would claim that if it got halfway empty, or halfway full, it wasn’t giving ’em refrigeration, see, so they would file claims on it, even though you knew darn well, there’s no way they could say that. After we once paid a few claims like that, why, then everybody would get next to it. So what we were doing, we were spending a lot of money and labor to get more ice into the car, chopping what was big chunks in there, chopping it up finer and filling it up. Of course, what we were doing by chopping it up finer, we were actually making the ice in there last longer, and by doing that you weren’t giving the refrigeration any more. You do better with chunks and you’re getting air through it, see. We didn’t have to tell the shippers that after they insisted on it.

The things we’d run into. One time, I’d just got back from Imperial Valley, I guess, and a guy from Portland called up, they were in trouble in Medford. I went up there, and what they were doing, the shippers all started ordering salted cars, in other words, salt the initial car when it went to their deck. Well, in a little layout like that, they were loading a lot of cars, 40, 50 cars a day in a small yard, and switching facilities weren’t too good. They had the railroad just tied up. And they weren’t all the same, one’d order two per cent salt, and this other guy wanted three per cent salt, see. So I got our agent, who was the traveling man in Portland, and I said, “Now let’s sit down and go to every one of these shippers.”

So I went in there and I told ’em, “Now you fellows are just spending your money and losing what you’re doing. You’re ordering these cars initially salted, and as soon as that salt hits the ice in there, that water starts pouring out.Then it gets to your shed, you open the doors, and it stands open for two hours while you load the car. You’ve used up half of your tank of ice, and you haven’t got any use for it. If you’ll just load in a regular iced car, and say you want initial icing with two per cent salt, and bill it that way, then you’ll get the full refrigeration that you’re entitled to.” Well, they could see that they were just wasting their money doing that, see. So I got ’em all to either decide on two per cent or three per cent when they billed the car, then when it got to the ice deck we could take care of it.

Q. So you mean you put the salt in after it was loaded, instead of before?

A. Yeah, after it was loaded, initial icing. Then you really start doing a cooling job. But before, you were doing the cooling job, and then open the doors wide open for two or three hours while you were loading the car.

Q. Was icing done the same way in the east?

A. I had a chance once to see ice decks in the east. I made a trip, I was the PFE man, and we had a man from the MDT, one from the ART, and one from the Santa Fe. Somebody’d been screaming, I guess, about the various ice capacity of the cars, see, so we started out and made a circuit around the country, filling these bunkers up, icing ’em full, and measuring if the bunkers compared to what they said they were. We had a lot of fun on that trip. The guy from the Santa Fe was quite a joker, and the guy from the MDT, he was a very pompous guy, you know. This is in the summertime that we made this trip. The first thing the Santa Fe guy did to him, why, we were out around the ice deck in the railroad yards, and he found a piece of a brake shoe, you know, and he slipped that into his suitcase.

Then we got to, where the hell was that, Kansas City, I guess. Anyway, the ice deck was, no, it was further east, on the MDT, I guess, and we were on this ice deck, and they had quite an office up on the top of it, you know, and it had a great big stove in there, about that high, and that sort of thing. Mac, we called him, MacCarty, he was an Irishman, the Santa Fe guy. He looked at this stove, see, and this MDT guy was in there making up all the figures, you know, getting the car number and the measurements and one thing and another. So he slipped a match into that stove and went out, you know. The rest of us were out in the yard, and this guy was up in that office, doing his work, see, and he come out just wringing wet. “I don’t know how it got so damn hot.” The stove was red hot, with all that paper in it.

Then we were in the Muehlebach Hotel in Kansas City, and Mac was a good friend of the maitre d’ in the bar. We’d been in there and had dinner and one thing and another, and he kept slipping silverware in this guy’s pocket. When we went out the door, a guy stopped him, see, slapped his coat, says “What in hell?” and started pulling out this silverware. Oh, that guy was fit to be killed.

Q. This was MacCarty arranging all this?

A. Oh, yeah. I had a picture of that gang, that I ran across the other day, taken somewhere back there, out on the ice deck, watching ’em ice cars.

Q. What did they decide about those tests, the car capacities?

A. Oh, they decided they were all right. I guess they took all the figures, and they found what went into ’em was at least within the ballpark of being what they rated in the book. It always depends on, you know, what kind of a job you do. You can be three, four, five hundred pounds off, if you just throw in chunks and don’t chop it down too much, and leave a lot of vacancies in there.

Q. It must have been pretty variable, sure.

A. It’s the same way with estimating how much ice you’re going to put in a car. See, all the charges are based on the estimates.

Q. Oh, is that right? So that’s what the estimator is doing, walking down the cars. He’s looking in the bunkers, to see how empty they are.

A. Yeah, and writing down the car numbers, and how much ice is going to go in here, see.

Q. Why wouldn’t they just have the guys on the deck fill up each one?

A. Well, they do, but you’ve got to have that record, so much ice, see, for each station, and claim records are based on a lot of those records. If you missed icing it, why, you’re going to pay for it. Of course, the refrigeration charge was a set amount to a certain station, see, California to Pittsburgh and so forth. But your record has got to show that it’s been iced at each station, and how much ice went in there.

Q. So the shipper didn’t specify how often it was iced, they just sent it.

A. That’s right, standard refrigeration, and, like citrus, you can bill it “one icing,” and so forth.

Q. You mean it would just get iced once in transit, then?

A. Yeah. You would do that when it wasn’t too warm.

Q. So the PFE didn’t have anything to do with how it was iced?

A. No, the bill of lading would say how he wanted it, what the refrigeration should be, see.

Q. The shipper would put that.

A. Yeah, he said “standard refrigeration,” or “one icing in transit,” at, say, Kansas City. He’d say where he wanted it iced again, see.

Q. Then the railroad just followed the bill of lading when they handled the car, unless a car missed a connection or something.

A. Yeah, you just follow the billing.

Q. So the shipper would have to know something about what to expect.

A. Yeah, yeah, he’s got to know, but they all had traffic managers. A few of our boys have turned over to be traffic managers, see, because all that stuff has diversions on it, too, you know. Every car, all those cars out of Imperial Valley might be billed way short of where you want to go. One or two shippers would bill everything to El Paso, see. Before the car got to El Paso, they’d change the destination, so that it would go to Chicago, or go to New Orleans, or wherever you want.

Q. Depending on the market, I guess.

A. Yeah, and on where your sales were. The diversion part of it was a big part of our business, see, handling all the perishable diversions.

Q. They must have been charged for those diversions, or weren’t they?

A. No, I think they got three for free.

Q. That sounds like a lot of work for PFE.

A. Yeah, well, especially when you get into stuff like Mexican tomatoes, diversions on every car, because they were only billed to the border to start with, and you got that Mexican waybill, and all the stuff that goes on at Nogales, that was a job. And then they diverted, except for the local ones.

And then you get the Canadian shipments. You’d get a Canadian shipment that’s diverted to someplace in the United States. You ship it in bond, and then you got to get somebody to open the car for you.

Q. Did the shipper just phone up his local agent, and tell him how many cars he wanted that day? I suppose you had no way to know what he needed.

A. Oh, yeah, they had to order the cars.

Q. Did they do it in advance, or could they tell you the same day?

A. Well, they’d order, they might increase their order, if it’s locally, see. If you’re way out in the country someplace, it has to be in the night before. We generally got our orders in the afternoon or early in the evening, for the following day’s loads, see, so you’d know how many to ice in advance.

Q. And from experience, you’d know how many cars to have on hand at that town.

A. Yeah, oh, yeah. Of course, most of it moves out of a central point. In Los Angeles, everything came out of Los Angeles Yard [Taylor], for all that citrus territory down through there. But Imperial Valley, it’d be right in the town, El Centro, Brawley, Calexico, because the local switch engines in those towns were stationed there.

Q. So then did PFE tell the SP crews how to handle the cars?

A. Yeah, the shipper would order the cars, and we’d give a list to the SP.

Q. It was a big operation, wasn’t it?

A. You ain’t kidding. When you deal with that many cars a day down there. . .

Pete loved to tell PFE stories, and he seemed to have an endless supply. I’ll post more of them soon. He passed away in 1992, and as with so many old-timers, an awful lot of knowledge passed with him.

Tony Thompson

In this post I present a small part of two long interviews with A.L. “Pete” Holst, who worked his whole career for PFE, starting in 1917. He retired as Assistant General Manager for Car Service at San Francisco. My first interview was at hs home in San Mateo, on January 30, 1986. I will pick up somewhere around the middle, when we talked details of operations. My comments are denoted as “Q” for questioner, Pete’s answers as “A.”

A. I had a lot of arguments with some of the managers, after I was in Los Angeles down there, during the World War down there, you know, we had a lot of shortages of ice everywhere. I finally sat down with the old guy that ran the Santa Fe’s Refrigeration Department, and we pulled a lot of stuff, traded ice, switched ice, and everything else. I’d give him ice if he was short, give him ice from Colton, and he’d give me ice from Bakersfield. We saved a hell of a lot of cross-hauling of ice.

Q. Was that plant in Bakersfield theirs?

A. Well, they had a plant in Bakersfield, and we had a plant, but they had a bigger plant than we did. They had a big plant at San Bernardino, that’s where their big plant was. When I needed ice in Imperial Valley, and I ran out of the other sources, why, I traded ice up the valley with the Santa Fe. We saved a lot of cross-hauling. For years we’d been shipping ice right by their ice plants, and one thing and another. So we got a break with old John Daly, and he was glad to get it.

Q. I suppose the Santa Fe reefers didn’t show up on SP tracks, for SP shippers to use. Or did you use them if you needed the empties?

A. No, no, we didn’t trade with the Santa Fe on cars. They were a little too jealous for that. We wouldn’t let a Santa Fe car be loaded on our line either. We switched ’em back and forth down there, of course, and if they were unloaded on the SP we turned ’em back, and they would, too. If PFE’s cars were unloaded on the Santa Fe, they’d give ’em back to us. We could always use ‘em.

Q. I’ve read that three sizes of ice were used on the deck, that were chunk, coarse, and crushed, I think. Is that right?

A. Yeah. You always had crushed ice for the meat cars, they generally took small pieces, you know, and you iced the frozen food cars with more or less smaller chunks.

Q. How big would those be?

A. Oh, they’d be 25, 30, 50 pounds. You chopped it up a little more because you were putting 30 per cent salt in ’em, see.

Q. Then you put the salt in, for the others?

A. No, you dump the salt in as you put the ice in. After you got it about half full, then you start pouring salt in.

Q. No, I meant for regular icing. Did they put in the whole cake, or whatever would fit in the hatch?

A. No, you’re never supposed to put that in. It’s supposed to be a quarter of a 300-pound cake. You cut it in half this long way, and then this way. We had a lot of trouble, you see, with the cars whenever they used to take over a half a tank of ice. The Claim Department, the claim clerks of the shippers, would claim that if it got halfway empty, or halfway full, it wasn’t giving ’em refrigeration, see, so they would file claims on it, even though you knew darn well, there’s no way they could say that. After we once paid a few claims like that, why, then everybody would get next to it. So what we were doing, we were spending a lot of money and labor to get more ice into the car, chopping what was big chunks in there, chopping it up finer and filling it up. Of course, what we were doing by chopping it up finer, we were actually making the ice in there last longer, and by doing that you weren’t giving the refrigeration any more. You do better with chunks and you’re getting air through it, see. We didn’t have to tell the shippers that after they insisted on it.

The things we’d run into. One time, I’d just got back from Imperial Valley, I guess, and a guy from Portland called up, they were in trouble in Medford. I went up there, and what they were doing, the shippers all started ordering salted cars, in other words, salt the initial car when it went to their deck. Well, in a little layout like that, they were loading a lot of cars, 40, 50 cars a day in a small yard, and switching facilities weren’t too good. They had the railroad just tied up. And they weren’t all the same, one’d order two per cent salt, and this other guy wanted three per cent salt, see. So I got our agent, who was the traveling man in Portland, and I said, “Now let’s sit down and go to every one of these shippers.”

So I went in there and I told ’em, “Now you fellows are just spending your money and losing what you’re doing. You’re ordering these cars initially salted, and as soon as that salt hits the ice in there, that water starts pouring out.Then it gets to your shed, you open the doors, and it stands open for two hours while you load the car. You’ve used up half of your tank of ice, and you haven’t got any use for it. If you’ll just load in a regular iced car, and say you want initial icing with two per cent salt, and bill it that way, then you’ll get the full refrigeration that you’re entitled to.” Well, they could see that they were just wasting their money doing that, see. So I got ’em all to either decide on two per cent or three per cent when they billed the car, then when it got to the ice deck we could take care of it.

Q. So you mean you put the salt in after it was loaded, instead of before?

A. Yeah, after it was loaded, initial icing. Then you really start doing a cooling job. But before, you were doing the cooling job, and then open the doors wide open for two or three hours while you were loading the car.

Q. Was icing done the same way in the east?

A. I had a chance once to see ice decks in the east. I made a trip, I was the PFE man, and we had a man from the MDT, one from the ART, and one from the Santa Fe. Somebody’d been screaming, I guess, about the various ice capacity of the cars, see, so we started out and made a circuit around the country, filling these bunkers up, icing ’em full, and measuring if the bunkers compared to what they said they were. We had a lot of fun on that trip. The guy from the Santa Fe was quite a joker, and the guy from the MDT, he was a very pompous guy, you know. This is in the summertime that we made this trip. The first thing the Santa Fe guy did to him, why, we were out around the ice deck in the railroad yards, and he found a piece of a brake shoe, you know, and he slipped that into his suitcase.

Then we got to, where the hell was that, Kansas City, I guess. Anyway, the ice deck was, no, it was further east, on the MDT, I guess, and we were on this ice deck, and they had quite an office up on the top of it, you know, and it had a great big stove in there, about that high, and that sort of thing. Mac, we called him, MacCarty, he was an Irishman, the Santa Fe guy. He looked at this stove, see, and this MDT guy was in there making up all the figures, you know, getting the car number and the measurements and one thing and another. So he slipped a match into that stove and went out, you know. The rest of us were out in the yard, and this guy was up in that office, doing his work, see, and he come out just wringing wet. “I don’t know how it got so damn hot.” The stove was red hot, with all that paper in it.

Then we were in the Muehlebach Hotel in Kansas City, and Mac was a good friend of the maitre d’ in the bar. We’d been in there and had dinner and one thing and another, and he kept slipping silverware in this guy’s pocket. When we went out the door, a guy stopped him, see, slapped his coat, says “What in hell?” and started pulling out this silverware. Oh, that guy was fit to be killed.

Q. This was MacCarty arranging all this?

A. Oh, yeah. I had a picture of that gang, that I ran across the other day, taken somewhere back there, out on the ice deck, watching ’em ice cars.

Q. What did they decide about those tests, the car capacities?

A. Oh, they decided they were all right. I guess they took all the figures, and they found what went into ’em was at least within the ballpark of being what they rated in the book. It always depends on, you know, what kind of a job you do. You can be three, four, five hundred pounds off, if you just throw in chunks and don’t chop it down too much, and leave a lot of vacancies in there.

Q. It must have been pretty variable, sure.

A. It’s the same way with estimating how much ice you’re going to put in a car. See, all the charges are based on the estimates.

Q. Oh, is that right? So that’s what the estimator is doing, walking down the cars. He’s looking in the bunkers, to see how empty they are.

A. Yeah, and writing down the car numbers, and how much ice is going to go in here, see.

Q. Why wouldn’t they just have the guys on the deck fill up each one?

A. Well, they do, but you’ve got to have that record, so much ice, see, for each station, and claim records are based on a lot of those records. If you missed icing it, why, you’re going to pay for it. Of course, the refrigeration charge was a set amount to a certain station, see, California to Pittsburgh and so forth. But your record has got to show that it’s been iced at each station, and how much ice went in there.

Q. So the shipper didn’t specify how often it was iced, they just sent it.

A. That’s right, standard refrigeration, and, like citrus, you can bill it “one icing,” and so forth.

Q. You mean it would just get iced once in transit, then?

A. Yeah. You would do that when it wasn’t too warm.

Q. So the PFE didn’t have anything to do with how it was iced?

A. No, the bill of lading would say how he wanted it, what the refrigeration should be, see.

Q. The shipper would put that.

A. Yeah, he said “standard refrigeration,” or “one icing in transit,” at, say, Kansas City. He’d say where he wanted it iced again, see.

Q. Then the railroad just followed the bill of lading when they handled the car, unless a car missed a connection or something.

A. Yeah, you just follow the billing.

Q. So the shipper would have to know something about what to expect.

A. Yeah, yeah, he’s got to know, but they all had traffic managers. A few of our boys have turned over to be traffic managers, see, because all that stuff has diversions on it, too, you know. Every car, all those cars out of Imperial Valley might be billed way short of where you want to go. One or two shippers would bill everything to El Paso, see. Before the car got to El Paso, they’d change the destination, so that it would go to Chicago, or go to New Orleans, or wherever you want.

Q. Depending on the market, I guess.

A. Yeah, and on where your sales were. The diversion part of it was a big part of our business, see, handling all the perishable diversions.

Q. They must have been charged for those diversions, or weren’t they?

A. No, I think they got three for free.

Q. That sounds like a lot of work for PFE.

A. Yeah, well, especially when you get into stuff like Mexican tomatoes, diversions on every car, because they were only billed to the border to start with, and you got that Mexican waybill, and all the stuff that goes on at Nogales, that was a job. And then they diverted, except for the local ones.

And then you get the Canadian shipments. You’d get a Canadian shipment that’s diverted to someplace in the United States. You ship it in bond, and then you got to get somebody to open the car for you.

Q. Did the shipper just phone up his local agent, and tell him how many cars he wanted that day? I suppose you had no way to know what he needed.

A. Oh, yeah, they had to order the cars.

Q. Did they do it in advance, or could they tell you the same day?

A. Well, they’d order, they might increase their order, if it’s locally, see. If you’re way out in the country someplace, it has to be in the night before. We generally got our orders in the afternoon or early in the evening, for the following day’s loads, see, so you’d know how many to ice in advance.

Q. And from experience, you’d know how many cars to have on hand at that town.

A. Yeah, oh, yeah. Of course, most of it moves out of a central point. In Los Angeles, everything came out of Los Angeles Yard [Taylor], for all that citrus territory down through there. But Imperial Valley, it’d be right in the town, El Centro, Brawley, Calexico, because the local switch engines in those towns were stationed there.

Q. So then did PFE tell the SP crews how to handle the cars?

A. Yeah, the shipper would order the cars, and we’d give a list to the SP.

Q. It was a big operation, wasn’t it?

A. You ain’t kidding. When you deal with that many cars a day down there. . .

Pete loved to tell PFE stories, and he seemed to have an endless supply. I’ll post more of them soon. He passed away in 1992, and as with so many old-timers, an awful lot of knowledge passed with him.

Tony Thompson

Tuesday, September 11, 2012

Modeling SP train orders -- Part 2

In my previous post on this topic, I showed some SP train orders from the 1950 era. In response to a couple of requests, I will show more of them in this post. That previous post can be viewed at this link: http://modelingthesp.blogspot.com/2012/09/modeling-sp-train-orders.html .

The first one I show here is a simple “right over” order, but involves several trains and two different territories of rights. It was issued at Lathrop in 1950, and is addressed to First 426, an eastward freight train, with rights over westward trains which otherwise would have superiority by direction.

This next one is also simple, setting the location of a meet and directing which train is to take the siding. It was issued at Maricopa, Arizona in 1952.

A third one is quite interesting in that it identifies an oversize load. Most train orders are thought of as directing train movements, but this one, issued at Tucson in 1952, is a cautionary order.

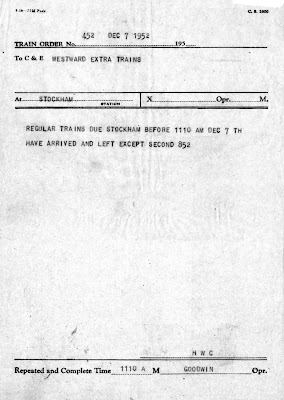

Most model layout operators are familiar with the concept of a “train register,” which is located at critical points, often at terminals or important junctions. Crews sign it when arriving or departing, and its purpose is to show that scheduled trains have in fact departed or arrived (since timetable authority continues for 12 hours after the time shown in the timetable, there would otherwise be no way to be certain of such arrivals or departures). This 1952 train order serves the same purpose in notifying westward trains of the situation at Stockham (just west of Tucson) regarding other trains.

All these are interesting examples and can be food for thought in model layout operations. As mentioned in my original post on this topic (cited at the top of this post), there are good written explanations of how train orders worked, if this is new to you.

TonyThompson

The first one I show here is a simple “right over” order, but involves several trains and two different territories of rights. It was issued at Lathrop in 1950, and is addressed to First 426, an eastward freight train, with rights over westward trains which otherwise would have superiority by direction.

This next one is also simple, setting the location of a meet and directing which train is to take the siding. It was issued at Maricopa, Arizona in 1952.

A third one is quite interesting in that it identifies an oversize load. Most train orders are thought of as directing train movements, but this one, issued at Tucson in 1952, is a cautionary order.

Most model layout operators are familiar with the concept of a “train register,” which is located at critical points, often at terminals or important junctions. Crews sign it when arriving or departing, and its purpose is to show that scheduled trains have in fact departed or arrived (since timetable authority continues for 12 hours after the time shown in the timetable, there would otherwise be no way to be certain of such arrivals or departures). This 1952 train order serves the same purpose in notifying westward trains of the situation at Stockham (just west of Tucson) regarding other trains.

All these are interesting examples and can be food for thought in model layout operations. As mentioned in my original post on this topic (cited at the top of this post), there are good written explanations of how train orders worked, if this is new to you.

TonyThompson

Friday, September 7, 2012

Modeling meat reefers -- Part 3

My first post on my modeling project of meat refrigerator cars was a background description of the prototypes I wanted to model. I discussed that subject at: http://modelingthesp.blogspot.com/2011/02/modeling-meat-reefers.html . As I stated there, my intention was to use the old LifeLike one-piece plastic body reefer as a starting point (it was a Varney product originally). It has the right proportions and is 37 feet long, thus is suitable as a meat car.

The first part of the modeling was to remove all cast-on grab irons and ladders from car sides, and to model a board roof for cars that had them. Then separate wire grabs were installed, with complete grab iron rows at ladder locations for cars that had them. This was described in my second post, at: http://modelingthesp.blogspot.com/2012/01/modeling-meat-reefers-2.html .

My next step was to replace the snap-in “Talgo” trucks that came with these models. My preference is for screw attachments for trucks, and body-mounted couplers are absolutely standard in my fleet. I showed how I do that in a separate post: http://modelingthesp.blogspot.com/2012/03/replacing-snap-in-trucks.html .

The third part of the modeling project was installation of underbody brake gear. By the year I model, 1953, nearly all cars had AB brakes, as the deadline to replace K brakes was right around the corner, so the models all got AB brakes. The simplified approach to this brake gear was shown in a post about that subject, at: http://modelingthesp.blogspot.com/2012/08/simplified-underframe-brake-gear.html .

The next step in completing the body detailing involved insertion of A-Line sill steps, which had already been attached when the brake gear was installed. These sill steps are clearly visible in the photos accompanying the brake gear post, cited above. I also added a Cal-Scale Ajax handbrake (in set 283, source of the rest of the brake gear also) to the two cars for which it was suitable, and used Tichy ladders (part 3066) for the Cudahy car which had them. The board-roof cars needed to have ice hatches applied (strictly speaking, ice hatch covers), and I used Grandt hatches (part 5106) for one car, and some old Cannonball Car Shops hatches (part 31038) from my parts drawer for the other. These CCS parts were styrene injection-molded reproductions of the original metal Red Ball parts.

At this point, it was time to address the painting of the cars. The original LifeLike red lettering on the white plastic bodies was pretty resistant to a couple of paint strippers, and was only partly removed. You can see that clearly in the last photo in the post about replacing snap-in trucks. Since car sides were to be yellow or orange, I wanted to make sure the old lettering would not show through. The best solution to this is a thin primer coat of light gray, so that was my next step.

The light gray would also moderate the black roofs of the cars with original LifeLike roofs, since otherwise the final boxcar red color might be too dark over the black, compared to the white ends. Accordingly, I wanted to prime both roofs and sides of the project cars. The color I used was Floquil “SP Lettering Gray,” a light color and one I have around for other uses.

Once the primer was dry, a couple of minor boo-boos had to be corrected (primer is a great way to highlight those little blunders you hadn’t noticed or were trying to ignore). Then I airbrushed the sides yellow. When color shots of yellow prototype cars are viewed, they are not a bright or lemon yellow, but are a deeper color tending toward gold (but not metallic, of course). I have used several paint colors to reproduce this look, including Floquil’s MEC Harvest Gold, CNW Yellow and Railbox Yellow; here I used the Railbox color. As this is the lightest finish color, it went on first. I followed that by painting the underframe Grimy Black.

You can see the sill steps are black in this view, and some gray primer is visible on the roof and end. This is the car with Cannonball ice hatches and a board roof. The roof corner grab irons have not been installed yet. The trucks, incidentally, are a pair of my “painting trucks,” which are used over and over under cars being painted and will likely never be used under a completed freight car.

The next step will be to mask the yellow and apply Boxcar Red on the roof and ends, followed by lettering. But I think I will postpone the final paint and lettering to a future post.

Tony Thompson

The first part of the modeling was to remove all cast-on grab irons and ladders from car sides, and to model a board roof for cars that had them. Then separate wire grabs were installed, with complete grab iron rows at ladder locations for cars that had them. This was described in my second post, at: http://modelingthesp.blogspot.com/2012/01/modeling-meat-reefers-2.html .

My next step was to replace the snap-in “Talgo” trucks that came with these models. My preference is for screw attachments for trucks, and body-mounted couplers are absolutely standard in my fleet. I showed how I do that in a separate post: http://modelingthesp.blogspot.com/2012/03/replacing-snap-in-trucks.html .

The third part of the modeling project was installation of underbody brake gear. By the year I model, 1953, nearly all cars had AB brakes, as the deadline to replace K brakes was right around the corner, so the models all got AB brakes. The simplified approach to this brake gear was shown in a post about that subject, at: http://modelingthesp.blogspot.com/2012/08/simplified-underframe-brake-gear.html .

The next step in completing the body detailing involved insertion of A-Line sill steps, which had already been attached when the brake gear was installed. These sill steps are clearly visible in the photos accompanying the brake gear post, cited above. I also added a Cal-Scale Ajax handbrake (in set 283, source of the rest of the brake gear also) to the two cars for which it was suitable, and used Tichy ladders (part 3066) for the Cudahy car which had them. The board-roof cars needed to have ice hatches applied (strictly speaking, ice hatch covers), and I used Grandt hatches (part 5106) for one car, and some old Cannonball Car Shops hatches (part 31038) from my parts drawer for the other. These CCS parts were styrene injection-molded reproductions of the original metal Red Ball parts.

At this point, it was time to address the painting of the cars. The original LifeLike red lettering on the white plastic bodies was pretty resistant to a couple of paint strippers, and was only partly removed. You can see that clearly in the last photo in the post about replacing snap-in trucks. Since car sides were to be yellow or orange, I wanted to make sure the old lettering would not show through. The best solution to this is a thin primer coat of light gray, so that was my next step.

The light gray would also moderate the black roofs of the cars with original LifeLike roofs, since otherwise the final boxcar red color might be too dark over the black, compared to the white ends. Accordingly, I wanted to prime both roofs and sides of the project cars. The color I used was Floquil “SP Lettering Gray,” a light color and one I have around for other uses.

Once the primer was dry, a couple of minor boo-boos had to be corrected (primer is a great way to highlight those little blunders you hadn’t noticed or were trying to ignore). Then I airbrushed the sides yellow. When color shots of yellow prototype cars are viewed, they are not a bright or lemon yellow, but are a deeper color tending toward gold (but not metallic, of course). I have used several paint colors to reproduce this look, including Floquil’s MEC Harvest Gold, CNW Yellow and Railbox Yellow; here I used the Railbox color. As this is the lightest finish color, it went on first. I followed that by painting the underframe Grimy Black.

You can see the sill steps are black in this view, and some gray primer is visible on the roof and end. This is the car with Cannonball ice hatches and a board roof. The roof corner grab irons have not been installed yet. The trucks, incidentally, are a pair of my “painting trucks,” which are used over and over under cars being painted and will likely never be used under a completed freight car.

The next step will be to mask the yellow and apply Boxcar Red on the roof and ends, followed by lettering. But I think I will postpone the final paint and lettering to a future post.

Tony Thompson

Monday, September 3, 2012

Electrical wars

Every layout is distinctive if not unique, so I am a little reluctant to talk about electrical issues on my layout. Obviously every layout has its own features and problems. But what I will try to do is indicate why I’m making changes (hopefully enhancements), which I suspect will be especially relevant for those with older layouts, originally wired for DC.

Those who haven’t made a move toward DCC may be thinking, “This is where I log out,” but some of these enhancements have nothing directly to do with DCC, and will improve the layout if operated in DC.

I should hasten to add that my present layout is mostly composed of sections from the layout I had in Pittsburgh, and that previous layout operated dependably, both with respect to trackwork and electrical arrangements. But some of the decisions I made in designing that layout no longer look like such bright ideas. They seemed all right at the time, but I now see their shortcomings.

One decision I had made was cut a minimum number of gaps, and route power to much trackage via turnouts. In some cases, this meant that track segments rather far from their power-routing points would be dead unless that routing turnout were thrown properly, even if a locomotive did not need to run through that turnout or was even quite a distance from that turnout. This can get old, especially as one becomes accustomed to the freedom to move locomotives almost everywhere with DCC.

The solution to that one is easily stated: just drop more feeders and cut more gaps. In other words, cut new gaps right at the formerly power-routing turnout, and feed the track on the other side of each gap so created. Then the turnout still routes power, but only to the frog, not to long stretches of track.

I use a battery-powered Dremel for cutting gaps, a very convenient and quick tool for this job (wearing eye protection, of course). I like to cut the gaps first, because then you really have to keep going with the project. Otherwise you have track out of service!

I use a smallish drill, 1/8-inch or smaller, to make holes for the new feeders. This photo shows work at Ballard. Here again, a battery-powered tool makes it easy.

After awhile I found I’d made ten holes here at Ballard—irresistibly reminding me of a line in the Beatles song (“A Day in the Life,” by John Lennon): “Four thousand holes in Blackburn, Lancashire, and though the holes were rather small . . .” Here are seven of mine. I can’t speak for the holes in Lancashire.

Completing this project was simple work, and because I have terminal strips very generously strewn around under the layout, it was easy to connect into the track power. Here I’m soldering feeders in existing track at Shumala.

More complex are some short circuits I have discovered recently, in trackage that never used to exhibit shorts. Microscopic examination of both track and existing wiring does not reveal any faults. (I am giving the very short version of this story, as I have put in a lot of time and effort not finding these faults.) So I am simply reconnecting much under-layout wiring to new terminal strips and panel controls. This is logically more complex than the re-gapping and re-feeding mentioned above, and is more work in sometimes cramped spaces under the layout. But as I have reworked layout sections, the result has been successful, so I’m continuing.

When doing electrical work like this, I always start by checking carefully with my Layout Notebook (briefly described in a previous post, at: http://modelingthesp.blogspot.com/2012/08/a-modeling-journal.html ) to make sure I understand all existing wiring and terminal strips. This also ensures that I’m ready to add notations to existing notebook pages to document the new wiring, or gaps, or both. The notebook page just cited illustrates the kind of information I archive.

A second point worth mentioning is that I use a multi-meter all the time to check track voltages and connectivity. I have known modelers who built and still maintain their layouts without recourse to a meter, and I have no idea how that’s possible. I know I couldn’t do it.

For background information, I often refer back to the basic books to make sure I correctly remember what to do. I have used the Kalmbach books for years and still find them useful and direct. On electrical matters, I like Andy Sperandeo’s Easy Model Railroading Wiring (Second Edition, 1999) and Lionel Strang’s DCC Made Easy (2003). There is quite a bit about DCC wiring issues in Andy’s book, but it’s nice to make sure I understand any situation as it’s described in both books. Both of these particular books currently appear to be out of print but I’m sure the equivalent Kalmbach books now in print would supply comparable information.

As I stated at the outset, the real purpose of this post is to remark on wiring improvements, which can be needed on any layout. Exactly how and where you do them is a personal matter, so I didn’t give any detail about that.

Tony Thompson

Those who haven’t made a move toward DCC may be thinking, “This is where I log out,” but some of these enhancements have nothing directly to do with DCC, and will improve the layout if operated in DC.

I should hasten to add that my present layout is mostly composed of sections from the layout I had in Pittsburgh, and that previous layout operated dependably, both with respect to trackwork and electrical arrangements. But some of the decisions I made in designing that layout no longer look like such bright ideas. They seemed all right at the time, but I now see their shortcomings.

One decision I had made was cut a minimum number of gaps, and route power to much trackage via turnouts. In some cases, this meant that track segments rather far from their power-routing points would be dead unless that routing turnout were thrown properly, even if a locomotive did not need to run through that turnout or was even quite a distance from that turnout. This can get old, especially as one becomes accustomed to the freedom to move locomotives almost everywhere with DCC.

The solution to that one is easily stated: just drop more feeders and cut more gaps. In other words, cut new gaps right at the formerly power-routing turnout, and feed the track on the other side of each gap so created. Then the turnout still routes power, but only to the frog, not to long stretches of track.

I use a battery-powered Dremel for cutting gaps, a very convenient and quick tool for this job (wearing eye protection, of course). I like to cut the gaps first, because then you really have to keep going with the project. Otherwise you have track out of service!

I use a smallish drill, 1/8-inch or smaller, to make holes for the new feeders. This photo shows work at Ballard. Here again, a battery-powered tool makes it easy.

After awhile I found I’d made ten holes here at Ballard—irresistibly reminding me of a line in the Beatles song (“A Day in the Life,” by John Lennon): “Four thousand holes in Blackburn, Lancashire, and though the holes were rather small . . .” Here are seven of mine. I can’t speak for the holes in Lancashire.

Completing this project was simple work, and because I have terminal strips very generously strewn around under the layout, it was easy to connect into the track power. Here I’m soldering feeders in existing track at Shumala.

More complex are some short circuits I have discovered recently, in trackage that never used to exhibit shorts. Microscopic examination of both track and existing wiring does not reveal any faults. (I am giving the very short version of this story, as I have put in a lot of time and effort not finding these faults.) So I am simply reconnecting much under-layout wiring to new terminal strips and panel controls. This is logically more complex than the re-gapping and re-feeding mentioned above, and is more work in sometimes cramped spaces under the layout. But as I have reworked layout sections, the result has been successful, so I’m continuing.

When doing electrical work like this, I always start by checking carefully with my Layout Notebook (briefly described in a previous post, at: http://modelingthesp.blogspot.com/2012/08/a-modeling-journal.html ) to make sure I understand all existing wiring and terminal strips. This also ensures that I’m ready to add notations to existing notebook pages to document the new wiring, or gaps, or both. The notebook page just cited illustrates the kind of information I archive.

A second point worth mentioning is that I use a multi-meter all the time to check track voltages and connectivity. I have known modelers who built and still maintain their layouts without recourse to a meter, and I have no idea how that’s possible. I know I couldn’t do it.

For background information, I often refer back to the basic books to make sure I correctly remember what to do. I have used the Kalmbach books for years and still find them useful and direct. On electrical matters, I like Andy Sperandeo’s Easy Model Railroading Wiring (Second Edition, 1999) and Lionel Strang’s DCC Made Easy (2003). There is quite a bit about DCC wiring issues in Andy’s book, but it’s nice to make sure I understand any situation as it’s described in both books. Both of these particular books currently appear to be out of print but I’m sure the equivalent Kalmbach books now in print would supply comparable information.

As I stated at the outset, the real purpose of this post is to remark on wiring improvements, which can be needed on any layout. Exactly how and where you do them is a personal matter, so I didn’t give any detail about that.

Tony Thompson

Saturday, September 1, 2012

Modeling SP train orders

Over the years I’ve collected a variety of Southern Pacific train orders, and naturally would like to use them in layout operations. When my layout was in Pittsburgh, PA, I had acquired a rather old SP train order, and used it as a basis to have pads of blank orders printed up. The one I had was yellow, so I ordered mine printed in yellow. I really wanted the tissue material (thus the nickname, “flimsy,” for these orders), but the printer I spoke to in Pittsburgh became rather pale at the thought of printing on tissue. I compromised with regular paper.

Here is what they looked like.

As is perhaps evident, the body of this blank is photocopied from an actual SP train order.

Now what about the header at the top? The company name and safety emblem were by no means standard in the era I model, the early 1950s, and in subsequent years, as I’ve acquired more SP order forms, I realize that they shouldn’t have those items at the top in my era, nor have I seen a yellow copy from the 1950s.

Nevertheless, I have (so far) stuck with a black & white version of this order blank. Here is an example of one of the period SP train orders I have, issued at Los Angeles in 1948:

Note that these two road engines are both cab-forwards.

As another example of a real one to refer to, this is an interesting order for two extra trains on the Ione Branch (you may click on it to enlarge, if you wish), dated in 1951:

This is especially interesting because my layout, which models an SP branch, can appropriately operate with similar orders. For example, this order could be issued, to run to the outer end of the branch and return:

This post is not the place to explore the topic of how train orders work and how they are used on a layout, but there are superb books which cover that in detail. Both the Kalmbach books on operation are equally good, though one is out of print (readily available used from on-line dealers). Currently available is Tony Koester’s Realistic Model Railroad Operation (2003). The other one is Bruce Chubb’s How to Operate Your Model Railroad (1977), an excellent and comprehensive book, and well worth seeking out.

I am still deciding whether to remove the SP railroad name and emblem from the top of my model train orders. It was more important on my Pittsburgh layout, where there was a short line operating in addition to the SP, and obviously orders needed to be clearly from one railroad or the other. That issue no longer applies, so I am leaning toward removing the name, and making my orders look just like the real SP ones.

Tony Thompson

Here is what they looked like.

As is perhaps evident, the body of this blank is photocopied from an actual SP train order.

Now what about the header at the top? The company name and safety emblem were by no means standard in the era I model, the early 1950s, and in subsequent years, as I’ve acquired more SP order forms, I realize that they shouldn’t have those items at the top in my era, nor have I seen a yellow copy from the 1950s.

Nevertheless, I have (so far) stuck with a black & white version of this order blank. Here is an example of one of the period SP train orders I have, issued at Los Angeles in 1948:

Note that these two road engines are both cab-forwards.

As another example of a real one to refer to, this is an interesting order for two extra trains on the Ione Branch (you may click on it to enlarge, if you wish), dated in 1951: