I recently received an interesting comment from a long-time reader of this blog. The comment was, that I had mentioned PFE express refrigerator cars many times, but rarely had provided anything comprehensive about them. This is probably true about the blog, because of the PFE book (Thompson, Church and Jones, Pacific Fruit Express, 2nd edition, Signature Press, 2000), for which I wrote all the parts about PFE cars. Let me see what I can add; also compare Chapter 5 in the PFE book.

The first point to recognize about PFE express reefers is that PFE owned a fleet of 300 very conventional wood-sheathed 50-foot cars, built by AC&F and General American during 1923–24, which were very similar to many other owners’ express cars in that period. One benefit for modelers in that fact is that a manufacturer can offer the “standard” General American express car in a variety of lettering schemes, and in fact Athearn (in the blue-box days) and Walthers have done just that.

As built, these cars had round roofs and flush ice hatches, that is, no hatch platforms, and side and end grab irons were arranged according to passenger-car practice. They were numbered 501–800. Below is a copy of a builder photo of these cars (AC&F photo, courtesy Gordon Mills).

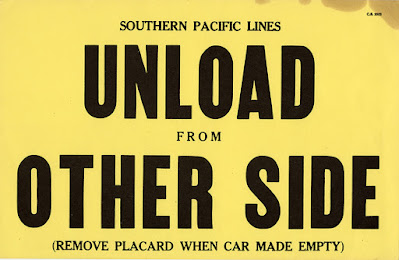

Note that the car is lettered for American Railway Express, the predecessor of the Railway Express Agency (REA), to whom the cars were leased for operation. Upon replacement of ARE with REA, the leases were terminated and cars returned to PFE. Subsequently, PFE, like most major owners of express reefers, voluntarily made them available for an REA pool.

As built, these cars were typified by a wide fascia board the full length of the car. Earl Hopkins, retired PFE General Mechanical and Engineering Officer, told me in an interview that these boards were 50-foot lengths of 10-inch wide clear redwood, as specified by PFE to the builder.

Beginning in 1930, PFE partially rebuilt these cars, adding ice hatch platforms, ladders on car sides and ends in place of grab-iron rows, and generally rearranging safety appliances in accord with freight car practice. (Both the old Athearn and the Walthers models are a mixture of these features, having flush ice hatches, but side and end ladders.)

Below is an in-service photo of one of the cars, showing that wide fascia board, taken at Roseville, California on May 7, 1956 (Chet McCoid photo, Bob’s Photo collection). Note that the car has a conventional power hand brake. These were

installed when many of the express cars were overhauled during 1942–46,

replacing Miner lever hand brakes. Note also that reporting mark and car number are to the right of the car door.

By 1953, the year I model, many cars were in poor condition, and PFE undertook to rebuild again 83 of the 155 cars then in service, about half of the fleet. Inside, the old wood superstructures were replaced with steel frames. The rebuilds are easy to recognize because the original wide fascia boards were replaced with a much narrower fir fascia board. Lettering was also revised, as seen in this photo at the Harborside Terminal, Jersey City, NJ, in 1958 (Jeff Winslow photo). Finally, fans were added (note fan symbol above nearer truck.)

Thus there are four different appearances shown by these express refrigerators, according to era. First, the as-built appearance, without ice hatch platforms or ladders. Second, the post-early thirties look with ice hatch platforms and ladders added. Third, the post-World War II look, with power hand brakes instead of lever hand brakes. Fourth, the final rebuilt look (only part of the fleet), with narrow fascia boards, from 1954 onwards.

For my own modeling, the post-World War II look, appearance 3, is appropriate for most if not all of my PFE express reefers. Probably the best commercial model of the post-WW II cars was the brass version by WP Car Company. I have a couple of these. Here is what they look like (weathered and in service on my layout):

Here is another model I have, weathered by Al Massi and traded to me by Otis McGee for a Richard Hendrickson PRR express reefer. I don’t specifically know the origin of the model, but it might be a Challenger brass import. In the early 1950s, the prototype cars had become rather dingy, and this model reflects that.

In the 1950s, there were also some quite interesting PFE express cars in the form of 40-foot steel reefers. I will summarize their history and modeling in a future post.

Tony Thompson