I began this series of posts with prototype information and photos, focusing on later classes of Southern Pacific 0-6-0 switchers, and discussed some related points, such as tenders. You can find that post at this link: https://modelingthesp.blogspot.com/2025/02/southern-pacific-steam-switchers.html .

I followed that with describing the mechanism work on the M.B. Austin HO scale brass model I have, along with a couple more prototype photos. (That second post is here: https://modelingthesp.blogspot.com/2025/04/an-sp-steam-switcher-part-2.html ). The work was done by Mark Schutzer.

Finally, I showed the remainder of Mark’s work on the model, the new, much larger boiler weight and the sound decoder and speaker in the tender. The post describing and illustrating those steps is located here: https://modelingthesp.blogspot.com/2025/04/an-sp-steam-switcher-part-3.html ). Next I touched up the paint, which was quickly completed, and then turned to lettering.

As most SP modelers know, we have a superb reference document for painting and lettering of SP locomotives, in the Southern Pacific Painting and Lettering Guide, Locomotives and Passenger Cars, by Jeff Cauthen and John Signor, 2nd edition, SP Historical & Technical Society, Upland, CA, 2019. I have relied on the information in this book in lettering my 0-6-0 model.

The overall locomotive and tender were black, with an aluminum-painted boiler front. In 1947, SP adopted a gray enamel, Lettering Gray, for all locomotive lettering (except Daylight steam locomotives). Any model lettering for non-Daylight locomotives that is white or silver is incorrect from 1947 onwards. This has been well understood by decal makers, including Microscale, Foothill Model Works, and California Locomotive Works.

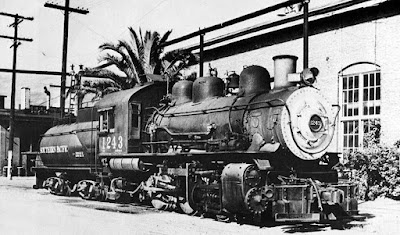

Here is a prototype photo which illustrates the locations of lettering elements (photographer unknown, Bob Brown collection, courtesy Clark Bauer). This is a Class S-10 engine at Bayshore, but lettering was the same on the Class S-12 engine that I am modeling. You can see the tender capacity data at the lower front of the tender, and engine class data under the cabside numbers. As was usually done, the road name on the tender is on the water compartment.

The points to be recognized in lettering a locomotive like this with a relatively small tender (7000 gallons of water) is that the road name on the tender after 1946 was only 9 inches high. Cab numerals, however, were to be 15 inches for all locomotives (again, except for Daylight schemes), and tender rear numerals 12 inches. I have used a mix of Microscale (set 87-105, SP Light Steam), and Foothill Model Works (sheet FMW-600, SP Steam), the latter using the excellent artwork of Charles H. Givens.

Here is a front view of the model, showing the engine number lettering

on the front number plate and on the (illuminated) sides of the

headlight casing. Here

the model has a coat of clear flat but is not yet weathered.

In addition to lettering, there is also some detail painting that is needed. Most SP steam locomotives had injectors and certain hot water and steam line valve handles painted some kind of red, which typically oxidized to a brownish-red color. I used Tamiya “Hull Red” (XF-9) for this.

Smokebox sides and stacks were painted with a graphite mixture, which gradually darkened and got dirty in service, but is usually evident in photos, as in the example above. I used Floquil “Graphite” for this. Smokebox fronts were painted aluminum, and number plates were black with aluminum numbers.

Cab window shades were canvas on an adjustable steel rod frame. When new, they were a khaki color, but of course got dirtier and dirtier until replaced. I used Tamiya “Deck Tan” (XF-78) for the base color, then used Pan Pastels to dirty it.

I also installed a cab apron in the model. What’s a cab apron? Prototype background and modeling techniques were described in a previous blog post (consult it at: https://modelingthesp.blogspot.com/2022/07/modeling-cab-aprons.html ). My first step in adding this part was to add a cab floor. The model had none, because the original mechanism had the open-frame motor extending back into the cab, with an appearance something like this (not my model).

With the new mechanism (see my “Part 2” post, linked in the top paragraph, above), this space is empty. I made a new floor from cardstock, and used the same material for a new apron (I have used styrene here in other locomotives). This effectively conceals the relatively large gap between engine and tender that is conventional in model locomotives.

Here is a rear view of the engine, switching on my layout at Shumala, showing the tender lettering,

including the “7000 gallons” legend at the bottom rear of the tank and the capacity data at lower front corner of the tank.

The model was lightly weathered using acrylic washes (see the “Reference pages” linked at the top right of the present post). But as that is a somewhat separate topic, I will conclude this post here.

Tony Thompson