I have written several posts about modeling railroad wheels, and will provide links below to prior posts. In the present post, I describe the wheel production process as it was practiced at Southern Pacific’s Sacramento General Shops (SGS) for many years. The basic description and most of the photos are from an article in the employee magazine, the Southern Pacific Bulletin (Pacific Lines), issue for July 1953. Here are those prior posts:

http://modelingthesp.blogspot.com/2016/04/truck-and-wheelset-modeling.html

http://modelingthesp.blogspot.com/2016/06/a-wheelset-work-area.html

On the prototype, steel wheels do experience wear, and have to be replaced when their tread contour falls outside preset limits. In the 1930s, there was extensive use of wheels with thicker treads, which could be re-contoured on a wheel lathe when worn. If capable of this rework for return to service one time, they were called two-wear wheels (abbreviated “2-W” in end lettering on freight cars), or if more than two wear cycles could be accommodated, they were multiple-wear wheels (abbreviated M-W). But such wheels necessarily were heavier than single-wear (or “1-W”) wheels, and railroads gradually concluded that carrying the extra wheel weight for the life of the wheel was not worth the savings versus new wheels.

Instead, cast wheels were recycled, at least on railroads with the capability to do so. Scrap wheels were moved to a central shop, then broken up into small enough pieces for convenient remelting, usually in a cupola furnace. Here is a pile of scrap wheels at SP’s SGS in the 1950s:

(All photos in this post are from Southern Pacific, published uncopyrighted and thus in the public domain.) Note that many wheels have ribbed backs, a strengthening feature of the wheel. These wheels of course have been pressed off their axles.

The cupola furnace at SGS could melt a charge of about 12,000 pounds of wheels (sometimes other high-carbon steel scrap would be included). To this charge would be added 50 to 60 pounds of limestone, a few pounds each of ferro-silicon and ferro-manganese to replenish alloying elements, and melted at about 2500• F. It was then heated above the melting temperature, to about 2750• F., and held for one and a half hours to homogenize the melt and allow impurities to migrate into the slag (floating on the iron) which formed from the limestone. The heat was then poured into smaller ladles for workmen to use in filling the wheel molds. Here is a photo of the cupola being bottom-tapped into a ladle.

The ladles were then moved over the sand molds encased in frames, and the molds filled with molten iron. The molds also contained steel “chillers” against what would become the wheel tread and flange, to accelerate cooling and raise the hardness of those areas. The chilled treads were also made uniform in dimensions by casting against these steel formers. Here are two workers filling a mold. The ladle looks big enough to fill four or five molds.

The entire foundry floor could accommodate a large number of wheel molds at a time. A full cupola charge of 12,000 pounds would produce about 15 wheels of 800 pounds each. Once the molds were filled, they were allowed to solidify and cool for 40 minutes, at which point they would be 1200 to 1400• F in temperature. Below is a view of the foundry from the crane catwalk. In this view, the crane is lifting a red-hot wheel from its mold.

The demolded wheels were then moved to annealing pits, originally simply sand-lined pits, but upgraded to insulated cylindrical steel tubes. In these pits, wheels were brought to a uniform 1400• for annealing, then cooled at a predetermined rate to room temperature over 72 hours. Once fully cooled, the new wheels were sandblasted. Shown below are new wheels freshly sandblasted. In the background are the 51 new annealing pits.

Once cleaned, the new wheels were inspected for any flaws, and also for dimensional correctness, using a circumference gauge. The photo at left shows Wheel Inspector Elmer Noe checking for circumference and flange dimensions. At right, Wheel Roller Felipe Casero has the skill to safely move these 800-pound wheels to where they are stored.

These new wheels could then be pressed onto axles and moved to regional shops for wheel replacement. Southern Pacific in the 1950s produced about 350 wheels a day in this foundry. If we assume 225 working days a year, and 350 wheels every working day, it’s an annual production of about 79,000 wheels, enough to equip 9800 freight cars. That’s about 20 percent of SP’s freight car fleet at the time, about 50,000 cars, implying that the average wheel lasted in service about five years.

I will return to some topics on freight car wheels and modeling in future posts. But I thought it might be interesting to see something about how one prototype managed this process.

Tony Thompson

Sunday, July 31, 2016

Thursday, July 28, 2016

A shout-out to Rapido Trains

I happened to travel Tuesday to the California State Railroad Museum in Sacramento to do some research on a couple of topics. (I may return to one or two of them in future posts.) But this post is about something that was encountered along the way.

Normally from my home in Berkeley, the simplest and by far the most pleasant way to go to Sacramento is by train, the CalTrans “Capitol Corridor” service. It is about an hour and 20 or 30 minutes by car, an hour and 45 minutes by train, and you are not driving bumper-to-bumper the whole way at 75 mph on Interstate 80 — if, that is, there are no accidents or other traffic tie-ups.

This is today a very convenient train service. There are 15 trains each way daily (11 daily on weekends or holidays), It isn’t quite hourly, but from the station at which I usually board, Emeryville, you can get eastward trains from 5:30 AM to 9:25 PM. The westward schedule is comparable. These are trainsets owned by the California Dept. of Transportation (CalTrans) and operated by Amtrak. Accordingly, crews and most paperwork is Amtrak.

What, you may be wondering, does all this have to do with Rapido Trains, a Canadian manufacturer of HO scale model train equipment? Here is the ticket jacket I was issued on departure, outer surfaces carrying ads as usual, and I was genuinely surprised by the front cover. Here it is, and you can click to enlarge:

Note the small lettering in white at the bottom of the photo: the locomotives pictured are Rapido models! Excellent graphical rendition, and an impressive idea on Rapido’s part.

I had not realized Rapido was advertising on Amtrak ticket folders — perhaps they do so throughout the U.S. — but kudos to them for doing so, bringing our hobby to the attention of the train-riding public as well as keeping their name in front of the miniscule percentage of ticket-buyers who are also model railroaders.

And if they advertise only in California or other selected markets, I still have to say congratulations, and well done. This is reaching a great many people, and who knows how many germs of hobby ideas will be planted by a passenger reading his or her ticket jacket.

Tony Thompson

Normally from my home in Berkeley, the simplest and by far the most pleasant way to go to Sacramento is by train, the CalTrans “Capitol Corridor” service. It is about an hour and 20 or 30 minutes by car, an hour and 45 minutes by train, and you are not driving bumper-to-bumper the whole way at 75 mph on Interstate 80 — if, that is, there are no accidents or other traffic tie-ups.

This is today a very convenient train service. There are 15 trains each way daily (11 daily on weekends or holidays), It isn’t quite hourly, but from the station at which I usually board, Emeryville, you can get eastward trains from 5:30 AM to 9:25 PM. The westward schedule is comparable. These are trainsets owned by the California Dept. of Transportation (CalTrans) and operated by Amtrak. Accordingly, crews and most paperwork is Amtrak.

What, you may be wondering, does all this have to do with Rapido Trains, a Canadian manufacturer of HO scale model train equipment? Here is the ticket jacket I was issued on departure, outer surfaces carrying ads as usual, and I was genuinely surprised by the front cover. Here it is, and you can click to enlarge:

Note the small lettering in white at the bottom of the photo: the locomotives pictured are Rapido models! Excellent graphical rendition, and an impressive idea on Rapido’s part.

I had not realized Rapido was advertising on Amtrak ticket folders — perhaps they do so throughout the U.S. — but kudos to them for doing so, bringing our hobby to the attention of the train-riding public as well as keeping their name in front of the miniscule percentage of ticket-buyers who are also model railroaders.

And if they advertise only in California or other selected markets, I still have to say congratulations, and well done. This is reaching a great many people, and who knows how many germs of hobby ideas will be planted by a passenger reading his or her ticket jacket.

Tony Thompson

Monday, July 25, 2016

Examples of Richard Hendrickson freight cars

I have written about a variety of Richard’s freight car models in earlier posts. I showed his open-car loads in two earlier posts, links to which are below. The first of these showed loads which required more than one car for their movement.

http://modelingthesp.blogspot.com/2015/03/richard-hendricksons-multi-car-loads.html

http://modelingthesp.blogspot.com/2015/09/more-richard-hendrickson-open-car-loads.html

I also showed a selection of his lumber loads (which can be viewed at: http://modelingthesp.blogspot.com/2015/06/richard-hendricksons-lumber-loads.html . These are on flat cars and thus are also open-car loads.

By the way, anyone not sure who Richard was, or has perhaps forgotten, might find my memorial post of interest, and it can be seen at this link: http://modelingthesp.blogspot.com/2014/07/in-memoriam-richard-hendrickson.html .

In the present post, I want to show other aspects of his modeling. I will begin with what I regard as a wonderfully weathered model, a C&EI box car with billboard initials. But as you see here, such lettering might well be seriously dirty after a range of years in service. In this photo, C&EI 64198 has reweigh and repack stencils consistent with Richard’s modeling date of October 1947, but for use on my layout, I have since re-patched and re-decaled these data for my 1953 era.

Richard especially liked tank car models, and had built quite a number. I did keep a few of them. One of my own favorites was the Magnolia car, which he had weathered pretty heavily. The white paint scheme for which Magnolia was famous had been discontinued around the start of World War II, and of course almost all tank cars got dirty and were rarely repainted, so even by 1947, any surviving white Magnolia cars would be seriously grimy. Here is Richard’s representation of that appearance, on MPCX 797.

My next example is from another one of Richard’s favorite subjects, the Santa Fe’s refrigerator car fleet. He depicted one of the SFRD cars from the days before icing machines, when Santa Fe followed the distinctive practice of arranging its ice hatches to open toward the car center, rather than toward the car end as nearly every other owner did. This is the “map side” of SFRD 35719.

Because I model Southern Pacific and its Pacific Fruit Express refrigerator car subsidiary, I should not ever operate this SFRD car on my layout as being loaded outbound from a packing house, but it can be loaded inbound, for example to my wholesale grocer.

I might not have chosen to mention this next model, as it was identified in the post cited at the top of the present post, about multi-car loads. But the photo there was an almost-overhead view. To show the car a little more clearly, here is a side view of SP 94033, Class G-50-13. In service, of course, a load like this would have to have an idler flat car under the near end, and that is how this car was portrayed in the post on multi-car loads.

Lastly, I will show one of the cars Richard prepared to include in the weathering clinic he and I presented jointly several times. This is from the earliest Union Pacific covered hopper class, CH-70-1, which was indeed painted boxcar red, though UP joined most other railroads in painting subsequent classes medium gray. I like the way the cement streaking was handled.

This modest selection is only intended as a sampler. Quite a few more of Richard’s models were auctioned on line last month, and the photos of them remain available on Google Drive for anyone who wants to see them. Here are the links:

https://drive.google.com/open?id=0Bz_ctrHrDz4wdVlRVkxlWXQ3RUE

https://drive.google.com/file/d/0Bz_ctrHrDz4wSDdoR1dkRWRCNFE/view?usp=sharing

I am proud to have these and a few others of Richard’s cars now operating on my layout. They have certainly enhanced both the variety and the quality of my freight car operations.

Tony Thompson

http://modelingthesp.blogspot.com/2015/03/richard-hendricksons-multi-car-loads.html

http://modelingthesp.blogspot.com/2015/09/more-richard-hendrickson-open-car-loads.html

I also showed a selection of his lumber loads (which can be viewed at: http://modelingthesp.blogspot.com/2015/06/richard-hendricksons-lumber-loads.html . These are on flat cars and thus are also open-car loads.

By the way, anyone not sure who Richard was, or has perhaps forgotten, might find my memorial post of interest, and it can be seen at this link: http://modelingthesp.blogspot.com/2014/07/in-memoriam-richard-hendrickson.html .

In the present post, I want to show other aspects of his modeling. I will begin with what I regard as a wonderfully weathered model, a C&EI box car with billboard initials. But as you see here, such lettering might well be seriously dirty after a range of years in service. In this photo, C&EI 64198 has reweigh and repack stencils consistent with Richard’s modeling date of October 1947, but for use on my layout, I have since re-patched and re-decaled these data for my 1953 era.

Richard especially liked tank car models, and had built quite a number. I did keep a few of them. One of my own favorites was the Magnolia car, which he had weathered pretty heavily. The white paint scheme for which Magnolia was famous had been discontinued around the start of World War II, and of course almost all tank cars got dirty and were rarely repainted, so even by 1947, any surviving white Magnolia cars would be seriously grimy. Here is Richard’s representation of that appearance, on MPCX 797.

My next example is from another one of Richard’s favorite subjects, the Santa Fe’s refrigerator car fleet. He depicted one of the SFRD cars from the days before icing machines, when Santa Fe followed the distinctive practice of arranging its ice hatches to open toward the car center, rather than toward the car end as nearly every other owner did. This is the “map side” of SFRD 35719.

Because I model Southern Pacific and its Pacific Fruit Express refrigerator car subsidiary, I should not ever operate this SFRD car on my layout as being loaded outbound from a packing house, but it can be loaded inbound, for example to my wholesale grocer.

I might not have chosen to mention this next model, as it was identified in the post cited at the top of the present post, about multi-car loads. But the photo there was an almost-overhead view. To show the car a little more clearly, here is a side view of SP 94033, Class G-50-13. In service, of course, a load like this would have to have an idler flat car under the near end, and that is how this car was portrayed in the post on multi-car loads.

Lastly, I will show one of the cars Richard prepared to include in the weathering clinic he and I presented jointly several times. This is from the earliest Union Pacific covered hopper class, CH-70-1, which was indeed painted boxcar red, though UP joined most other railroads in painting subsequent classes medium gray. I like the way the cement streaking was handled.

This modest selection is only intended as a sampler. Quite a few more of Richard’s models were auctioned on line last month, and the photos of them remain available on Google Drive for anyone who wants to see them. Here are the links:

https://drive.google.com/open?id=0Bz_ctrHrDz4wdVlRVkxlWXQ3RUE

https://drive.google.com/file/d/0Bz_ctrHrDz4wSDdoR1dkRWRCNFE/view?usp=sharing

I am proud to have these and a few others of Richard’s cars now operating on my layout. They have certainly enhanced both the variety and the quality of my freight car operations.

Tony Thompson

Friday, July 22, 2016

Route cards, Part 14 — still more examples

This is the fourth post in a series which primarily displays a range of prototype route cards from the collection of Ralph Heiss. Ralph was kind enough to scan these cards for my use. The previous three posts, containing 20-some examples of cards, are at the following links:

http://modelingthesp.blogspot.com/2016/07/route-cards-part-11-examples.html

http://modelingthesp.blogspot.com/2016/07/route-cards-part-12-more-examples.html

http://modelingthesp.blogspot.com/2016/07/route-cards-part-13-other-examples.html

The present post concludes this series with a number of additional cards, all of which appear to be intended for local switching (though of course it isn’t possible to be sure).

This first group of cards contains a striking one with the blue diagonal stripe, a Pacific Electric card for automobile car SP 193787, to the Schrimp Co. in Los Nietos, California. The other two are Union Pacific cards, the one in the center marked to Fullerton, the one on the right for car CNW 3103, directed to Corn Products Refining Company.

The next set shows some examples from widely separated places. The one on the left, from the Texas City Terminal Railway Co., is for empty tank car SHPX 9965 and the consignee is the G & C Chemical plant. The center card from the St. Louis-San Francisco is marked for zone 91, the Sherman Denison Subdivision (Texas). At right is a car from the Kansas City Terminal Railway Company, for car ATSF 93695, moving from Massey Concrete Products to the Santa Fe itself in Calwa, California (Fresno).

Now I turn to a pair of rectangular cards, the one on the the left a UP card for car MP 87334, to be switched to Whittier Glass, while on the right is a Missouri Pacific card for District 9, Zone 4, C.M.O. North, but the consignee and car information has faded away.

Another interesting pair of cards forms the next group. The one on the left is not identified by railroad, though it resembles SP and UP cards, and is clearly printed with Colton, a place served by both railroads. Contents are shown as merchandise. The number 90 may be a train or a switching zone. Another zone number is probably the meaning of the number 6 on the one on the right from the Central of Georgia, for PFE 66498, a load of lettuce.

The next group is all Union Pacific forms, though all three are different. The one on the left, for car SAL 27460, is to Pacific Cartage and is stamped 292 and amended to 292-02, which I believe is a switch job. The center card is to hold a car, though no writing can be discerned on it, and the one on the right directs the car to be switched to UP North Platte.

Finally, two more examples, both complex and interesting, beginning on the left with a form from the New Orleans Public Belt Railroad, for car NP 27605, with a load of rubber from the Streicher Line, destined to Goodyear Tire & Rubber in Topeka, Kansas, moving initially via the T&NO. At right is a Minnesota Transfer Railway Co. form for car L&N 16614, carrying a load of Cream of Wheat to Philadelphia.

All these cards are individually interesting, and in toto they amount to a fascinating insight (for me, anyway) into an important yet obscure process of identifying car movements. Many have a very bold number code on them, which could be discernible in HO scale, but many do not, and are probably acceptably modeled with a plain rectangle of paper, Practically all are white or manila, in the ones I have shown, but color photos from the transition era do show other color cards, pink, yellow, blue and green in examples I have seen. I continue to think that these are interesting items to add to your models!

Tony Thompson

http://modelingthesp.blogspot.com/2016/07/route-cards-part-11-examples.html

http://modelingthesp.blogspot.com/2016/07/route-cards-part-12-more-examples.html

http://modelingthesp.blogspot.com/2016/07/route-cards-part-13-other-examples.html

The present post concludes this series with a number of additional cards, all of which appear to be intended for local switching (though of course it isn’t possible to be sure).

This first group of cards contains a striking one with the blue diagonal stripe, a Pacific Electric card for automobile car SP 193787, to the Schrimp Co. in Los Nietos, California. The other two are Union Pacific cards, the one in the center marked to Fullerton, the one on the right for car CNW 3103, directed to Corn Products Refining Company.

The next set shows some examples from widely separated places. The one on the left, from the Texas City Terminal Railway Co., is for empty tank car SHPX 9965 and the consignee is the G & C Chemical plant. The center card from the St. Louis-San Francisco is marked for zone 91, the Sherman Denison Subdivision (Texas). At right is a car from the Kansas City Terminal Railway Company, for car ATSF 93695, moving from Massey Concrete Products to the Santa Fe itself in Calwa, California (Fresno).

Now I turn to a pair of rectangular cards, the one on the the left a UP card for car MP 87334, to be switched to Whittier Glass, while on the right is a Missouri Pacific card for District 9, Zone 4, C.M.O. North, but the consignee and car information has faded away.

Another interesting pair of cards forms the next group. The one on the left is not identified by railroad, though it resembles SP and UP cards, and is clearly printed with Colton, a place served by both railroads. Contents are shown as merchandise. The number 90 may be a train or a switching zone. Another zone number is probably the meaning of the number 6 on the one on the right from the Central of Georgia, for PFE 66498, a load of lettuce.

The next group is all Union Pacific forms, though all three are different. The one on the left, for car SAL 27460, is to Pacific Cartage and is stamped 292 and amended to 292-02, which I believe is a switch job. The center card is to hold a car, though no writing can be discerned on it, and the one on the right directs the car to be switched to UP North Platte.

Finally, two more examples, both complex and interesting, beginning on the left with a form from the New Orleans Public Belt Railroad, for car NP 27605, with a load of rubber from the Streicher Line, destined to Goodyear Tire & Rubber in Topeka, Kansas, moving initially via the T&NO. At right is a Minnesota Transfer Railway Co. form for car L&N 16614, carrying a load of Cream of Wheat to Philadelphia.

All these cards are individually interesting, and in toto they amount to a fascinating insight (for me, anyway) into an important yet obscure process of identifying car movements. Many have a very bold number code on them, which could be discernible in HO scale, but many do not, and are probably acceptably modeled with a plain rectangle of paper, Practically all are white or manila, in the ones I have shown, but color photos from the transition era do show other color cards, pink, yellow, blue and green in examples I have seen. I continue to think that these are interesting items to add to your models!

Tony Thompson

Tuesday, July 19, 2016

Upgrading an Accurail BREX reefer

Sound familiar? Many reading this will have just recently read Mont Switzer’s fine article in Model Railroader (the issue for August 2016, page 36). I’m going to talk about the exact same starting point, an Accurail wood-sheathed refrigerator car decorated for Burlington Refrigerator Express (BREX). But as you’ll see, my project is different from Mont’s. I will quickly add that this is no reflection at all on Mont’s article or his modeling. It’s just because my objectives are different in two ways.

First, my starting point is not a kit, but a partly completed project by Richard Hendrickson, which I wanted to finish. Thus some decisions about how to do this model had already been made by Richard, and I decided not to second-guess those. Second, Richard and I were aiming at something different from Mont, in that we wanted to backdate the car to a prior era (originally, for Richard’s modeling time of October 1947). Both points lead to differences between my car and Mont’s, but not a better or (I hope) worse model.

(Anyone not sure who Richard was might find my memorial post of interest, and it is at this link: http://modelingthesp.blogspot.com/2014/07/in-memoriam-richard-hendrickson.html .)

Let me start with a prototype photo, contributed by Bill Welch. It shows the pre-1951 paint scheme on cars like this, with black side hardware and, equally visibly, the words VENTILATOR - REFRIGERATOR to the right of the car door. In the later paint scheme that Mont modeled, this was replaced by the word REFRIGERATOR only. The space under the door is boxcar red.

Visible in this image is that the truck centers are closer to the car end than is the case for the Accurail model. Mont corrected this on his model, but Richard had already built up and glued together the underframe, so that wasn’t at all readily fixable. I decided to let it go as it is.

Richard had also assembled simplified brake gear, as seen here. The brake cylinder is Tichy and the levers appear to be scale 1 x 6-inch styrene strip, while reservoir and valve are the Accurail kit parts. I will add brake rods, likely all that Richard planned to do, since the deep center sill would hide anything more. Note too that the molded-on sill steps are removed, so that metal ones can be added.

On the car body, Richard had completely stripped off the ends, much as Mont did, to permit the application of wire grab irons and free-standing ladders. But unlike Mont, Richard also stripped the ladders from the car side so they too could be re-applied as freestanding parts. Here is the left side of the car, showing the B end also, which has been stripped and sanded, but not repainted. Richard had already matched the paint on the car side where ladder and grabs had been removed, including the area of dimensional data at the right.

My own work began with the roof. Richard had removed the cast-on corner grab irons and repainted the area to match the factory roof color. I simply drilled the holes to attach my preferred corner grab iron parts, Detail Associates FC 6205.

Note here that I scribed the running boards crosswise, to indicate separate planks. Also, Richard had notched the molded-on hatch support bar. In the Mont Switzer article cited at the top of this post, a separate brass strip part was used for this, but Richard evidently was going to be content with the molded part, as modified.

I will continue with this project in a future post. Because I haven’t had a wood-sheathed BREX reefer in my fleet, this one will be a nice addition.

Tony Thompson

First, my starting point is not a kit, but a partly completed project by Richard Hendrickson, which I wanted to finish. Thus some decisions about how to do this model had already been made by Richard, and I decided not to second-guess those. Second, Richard and I were aiming at something different from Mont, in that we wanted to backdate the car to a prior era (originally, for Richard’s modeling time of October 1947). Both points lead to differences between my car and Mont’s, but not a better or (I hope) worse model.

(Anyone not sure who Richard was might find my memorial post of interest, and it is at this link: http://modelingthesp.blogspot.com/2014/07/in-memoriam-richard-hendrickson.html .)

Let me start with a prototype photo, contributed by Bill Welch. It shows the pre-1951 paint scheme on cars like this, with black side hardware and, equally visibly, the words VENTILATOR - REFRIGERATOR to the right of the car door. In the later paint scheme that Mont modeled, this was replaced by the word REFRIGERATOR only. The space under the door is boxcar red.

Visible in this image is that the truck centers are closer to the car end than is the case for the Accurail model. Mont corrected this on his model, but Richard had already built up and glued together the underframe, so that wasn’t at all readily fixable. I decided to let it go as it is.

Richard had also assembled simplified brake gear, as seen here. The brake cylinder is Tichy and the levers appear to be scale 1 x 6-inch styrene strip, while reservoir and valve are the Accurail kit parts. I will add brake rods, likely all that Richard planned to do, since the deep center sill would hide anything more. Note too that the molded-on sill steps are removed, so that metal ones can be added.

On the car body, Richard had completely stripped off the ends, much as Mont did, to permit the application of wire grab irons and free-standing ladders. But unlike Mont, Richard also stripped the ladders from the car side so they too could be re-applied as freestanding parts. Here is the left side of the car, showing the B end also, which has been stripped and sanded, but not repainted. Richard had already matched the paint on the car side where ladder and grabs had been removed, including the area of dimensional data at the right.

My own work began with the roof. Richard had removed the cast-on corner grab irons and repainted the area to match the factory roof color. I simply drilled the holes to attach my preferred corner grab iron parts, Detail Associates FC 6205.

Note here that I scribed the running boards crosswise, to indicate separate planks. Also, Richard had notched the molded-on hatch support bar. In the Mont Switzer article cited at the top of this post, a separate brass strip part was used for this, but Richard evidently was going to be content with the molded part, as modified.

I will continue with this project in a future post. Because I haven’t had a wood-sheathed BREX reefer in my fleet, this one will be a nice addition.

Tony Thompson

Saturday, July 16, 2016

Route cards, Part 13 — other examples

The previous two posts in this series contain examples of the prototype route cards in the collection of Ralph Heiss. (You can read the most recent one at this link: http://modelingthesp.blogspot.com/2016/07/route-cards-part-12-more-examples.html .) Many are from the 1950s and 1960s. Most were retrieved from freight cars in service, often on route card boards which had a number of cards stapled to them. According to folks who have worked in yards, there was no reason and usually no time to remove old route cards when adding new ones; the new card would simply be stapled atop the accumulation, or alongside it.

Before I show more cards, I want to address a question I received via email. The questioner wondered whether flat cars had route card boards, and if so, where. As with many open-top cars, a common location was near the left bolster, as you see on this SP car (between the second and third stake pockets from the left). The photo was taken April 16, 1950 at Ithaca, New York (Arnold Menke collection).

But as always, clerks did things as they liked, and with any car having wood parts, they might well staple that route card anywhere convenient. That's shown in this photo of a route card simply affixed to the end of the deck planking of the car (which is a Class F-70-2 car of the SP, in an SP photo). You can click on the photo to enlarge it.

Returning to prototype route cards themselves, one particular type of card directs a car to be switched to interchange with another railroad. I showed a number of such cards in an earlier post (which you can peruse at this link: http://modelingthesp.blogspot.com/2013/12/route-cards-8.html ), and the Ralph Heiss collection includes more of them, too. Here I show a few of them. The one on the left is a Peoria & Pekin Union card, and is directed to the Nickel Plate (the initials “NKP” are underneath the large numeral 8; you can click to enlarge). The middle card is especially interesting, as it is round instead of rectangular; it is an Alton & Southern card directing a car to the Cotton Belt interchange. The one on the right is probably a card to move cars to an SP interchange, though no additional information can be discerned on the card itself.

Another group of this card type is shown below. The one on the left is quite clearly an interchange card, moving a car from the Burlington to the Chicago Great Western. The one on the right is less clear, with the symbol “CRI” possibly referring to the Rock Island under its old mark of CRIP, but is probably some other symbol. It is for Great Northern car 43955 at Proviso Yard, and the destination is shown as Elmira, New York via the Erie. Thus CRI is likely an interchange symbol to the Erie. It is an unusual card in one other respect: it is dated and includes the year, Oct. 28, 1955.

A third group of these kinds of cards is shown next. The left-most card clearly is an assignment to a “Fast Freight” though the railroad or train symbol are not shown. The center one is a Union Pacific card directing a car, UP 188952, to the Southern Pacific. The card at right directs an empty SP car home to the SP, evidently at an interchange point or directly connected to one.

Lastly, two more interesting examples. The left-most is a Rock Island card directing car ATSF 17184 to a “Red Ball” train destined to Council Bluffs, Iowa, perhaps as symbol Q37A, or maybe that is a classification track. The round yard stamp is for Burr Oak Yard, Rock Island’s yard in Blue Island (Chicago area) which mostly made up westward trains. The card on the right, dated Feb. 11, 1956, is another Proviso Yard (Chicago) card, and the symbol “FRD” is likely a train symbol, though it could mean “forward.” The car identified is SP automobile car 64782.

As in the previous posts in this series, the format and appearance of these route cards varies greatly from one example to the next. In O or G scale, it would be possible to try and reproduce some of these “looks,” but in HO only the fattest lettering would be discernible. I really have enjoyed examining and trying to learn from these cards, so once again, my warm thanks to Ralph Heiss for sharing them.

Tony Thompson

Before I show more cards, I want to address a question I received via email. The questioner wondered whether flat cars had route card boards, and if so, where. As with many open-top cars, a common location was near the left bolster, as you see on this SP car (between the second and third stake pockets from the left). The photo was taken April 16, 1950 at Ithaca, New York (Arnold Menke collection).

But as always, clerks did things as they liked, and with any car having wood parts, they might well staple that route card anywhere convenient. That's shown in this photo of a route card simply affixed to the end of the deck planking of the car (which is a Class F-70-2 car of the SP, in an SP photo). You can click on the photo to enlarge it.

Returning to prototype route cards themselves, one particular type of card directs a car to be switched to interchange with another railroad. I showed a number of such cards in an earlier post (which you can peruse at this link: http://modelingthesp.blogspot.com/2013/12/route-cards-8.html ), and the Ralph Heiss collection includes more of them, too. Here I show a few of them. The one on the left is a Peoria & Pekin Union card, and is directed to the Nickel Plate (the initials “NKP” are underneath the large numeral 8; you can click to enlarge). The middle card is especially interesting, as it is round instead of rectangular; it is an Alton & Southern card directing a car to the Cotton Belt interchange. The one on the right is probably a card to move cars to an SP interchange, though no additional information can be discerned on the card itself.

Another group of this card type is shown below. The one on the left is quite clearly an interchange card, moving a car from the Burlington to the Chicago Great Western. The one on the right is less clear, with the symbol “CRI” possibly referring to the Rock Island under its old mark of CRIP, but is probably some other symbol. It is for Great Northern car 43955 at Proviso Yard, and the destination is shown as Elmira, New York via the Erie. Thus CRI is likely an interchange symbol to the Erie. It is an unusual card in one other respect: it is dated and includes the year, Oct. 28, 1955.

A third group of these kinds of cards is shown next. The left-most card clearly is an assignment to a “Fast Freight” though the railroad or train symbol are not shown. The center one is a Union Pacific card directing a car, UP 188952, to the Southern Pacific. The card at right directs an empty SP car home to the SP, evidently at an interchange point or directly connected to one.

Lastly, two more interesting examples. The left-most is a Rock Island card directing car ATSF 17184 to a “Red Ball” train destined to Council Bluffs, Iowa, perhaps as symbol Q37A, or maybe that is a classification track. The round yard stamp is for Burr Oak Yard, Rock Island’s yard in Blue Island (Chicago area) which mostly made up westward trains. The card on the right, dated Feb. 11, 1956, is another Proviso Yard (Chicago) card, and the symbol “FRD” is likely a train symbol, though it could mean “forward.” The car identified is SP automobile car 64782.

As in the previous posts in this series, the format and appearance of these route cards varies greatly from one example to the next. In O or G scale, it would be possible to try and reproduce some of these “looks,” but in HO only the fattest lettering would be discernible. I really have enjoyed examining and trying to learn from these cards, so once again, my warm thanks to Ralph Heiss for sharing them.

Tony Thompson

Wednesday, July 13, 2016

An interesting Hendrickson gondola project

One of several uncompleted projects on Richard Hendrickson’s workbench at the time of his passing was an intriguing detailing effort on a 65-foot mill gondola. In this post, I describe and illustrate that project, for what may be learned from it. But it is among the projects I intend to auction later this summer. I describe it here as an instructive approach for anyone who might wish to do some of the same things with a gondola model. (Anyone not sure who Richard was might find my memorial post of interest, and it is at this link: http://modelingthesp.blogspot.com/2014/07/in-memoriam-richard-hendrickson.html .)

The body is the recent 65-foot gondola model from Athearn. Richard was working to upgrade details in several areas, and was likely aiming at a model of one of the Santa Fe gondolas of this 65-foot type, which was from one of classes GA-47, -48, or -55, all built between 1937 and 1941 and all to the same design except for trucks. One thing needed to model these cars was to backdate them with original Dreadnaught ends in a reverse configuration, which Richard had already done. He modeled the drop end at one end of the car in the lowered position, doubtless because he was planning a load which would be longer than the car. Note the filled and sanded ejector pin marks in the sides and floor.

In the photo above, you see also the placard board that Santa Fe placed prominently at the center of the car side, in the form of a white styrene rectangle.

Also visible in the photo above is that Richard had rebuilt the corner posts on the car to more nearly match the Santa Fe prototype. At one corners, he had also added individual grab irons, sill step, and as the photo below shows, a retainer valve. The end in the dropped position is one of Richard’s own epoxy castings.

I should mention, incidentally, that all the prototype information for this model work is from Richard’s own book, Santa Fe Open-Top Cars: Flat, Gondola and Hopper Cars, 1902–1959, published by the Santa Fe Railway Historical and Modeling Society in 2009. Here is a photo from that book, showing the interior of one of these cars. Note the pivoting loops on the car side, which can be raised up to hold a side stake to restrain some kinds of loads. These are called stake holders.

To me, perhaps the most impressive part of Richard’s work was his decision to add the stake holders on the car interior. This are rarely modeled, and when molded in place are usually rather flattened. Instead, Richard decided to add them as brass wire parts. He had only added about a quarter of the ones needed, but you can see a good sample of them in this photo.

These were attached with CA.

Obviously one challenge in fabricating these little brass wire parts is to make them uniform. Richard built a steel tool to do so. Here is a photo of the tool, along with a few of the fabricated parts he hadn’t attached yet, and a piece of the wire.

This is 0.014-inch wire. I don’t know if there was a mating part to this tool, or if pliers were used to form wire over the tool shape (I think the latter — I have experimented, and it works). What I have photographed is everything that was in a single box for this project, so if there was a mating tool part, it has been lost.

Each of the car projects Richard was working on are interesting. This is only one. Last year I showed my completion of another of his gondola models, that one for the Wheeling & Lake Erie (you can read the post at: http://modelingthesp.blogspot.com/2015/05/completing-richard-hendrickson-freight.html ). There is a third gondola project which will be among the ones to be auctioned, a C&O gondola, and there are several box car-type projects too. I will be announcing this auction presently to the Steam Era Freight Car and Resin Freight Cars email lists on Yahoo, and can be contacted directly for additional information.

Tony Thompson

The body is the recent 65-foot gondola model from Athearn. Richard was working to upgrade details in several areas, and was likely aiming at a model of one of the Santa Fe gondolas of this 65-foot type, which was from one of classes GA-47, -48, or -55, all built between 1937 and 1941 and all to the same design except for trucks. One thing needed to model these cars was to backdate them with original Dreadnaught ends in a reverse configuration, which Richard had already done. He modeled the drop end at one end of the car in the lowered position, doubtless because he was planning a load which would be longer than the car. Note the filled and sanded ejector pin marks in the sides and floor.

In the photo above, you see also the placard board that Santa Fe placed prominently at the center of the car side, in the form of a white styrene rectangle.

Also visible in the photo above is that Richard had rebuilt the corner posts on the car to more nearly match the Santa Fe prototype. At one corners, he had also added individual grab irons, sill step, and as the photo below shows, a retainer valve. The end in the dropped position is one of Richard’s own epoxy castings.

I should mention, incidentally, that all the prototype information for this model work is from Richard’s own book, Santa Fe Open-Top Cars: Flat, Gondola and Hopper Cars, 1902–1959, published by the Santa Fe Railway Historical and Modeling Society in 2009. Here is a photo from that book, showing the interior of one of these cars. Note the pivoting loops on the car side, which can be raised up to hold a side stake to restrain some kinds of loads. These are called stake holders.

To me, perhaps the most impressive part of Richard’s work was his decision to add the stake holders on the car interior. This are rarely modeled, and when molded in place are usually rather flattened. Instead, Richard decided to add them as brass wire parts. He had only added about a quarter of the ones needed, but you can see a good sample of them in this photo.

These were attached with CA.

Obviously one challenge in fabricating these little brass wire parts is to make them uniform. Richard built a steel tool to do so. Here is a photo of the tool, along with a few of the fabricated parts he hadn’t attached yet, and a piece of the wire.

This is 0.014-inch wire. I don’t know if there was a mating part to this tool, or if pliers were used to form wire over the tool shape (I think the latter — I have experimented, and it works). What I have photographed is everything that was in a single box for this project, so if there was a mating tool part, it has been lost.

Each of the car projects Richard was working on are interesting. This is only one. Last year I showed my completion of another of his gondola models, that one for the Wheeling & Lake Erie (you can read the post at: http://modelingthesp.blogspot.com/2015/05/completing-richard-hendrickson-freight.html ). There is a third gondola project which will be among the ones to be auctioned, a C&O gondola, and there are several box car-type projects too. I will be announcing this auction presently to the Steam Era Freight Car and Resin Freight Cars email lists on Yahoo, and can be contacted directly for additional information.

Tony Thompson

Sunday, July 10, 2016

Route cards, Part 12 — more examples

In a previous post, I showed a number of prototype route cards from the collection of Ralph Heiss, and commented on the various switching and train identifications they appear to have been used for. (That post can be found at this link: http://modelingthesp.blogspot.com/2016/07/route-cards-part-11-examples.html .) But the images he sent me from his collection include a number of other types of route cards.

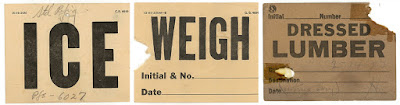

Here are a few evidently used on outgoing cars from a shipper or yard. It appears that they describe needed actions (weigh, ice) or the cargo on board (lumber). These of course are not destination cards except in the sense that weighing the car, or icing it, might be the first things before departure. The lumber card may describe a cargo with special needs, or may simply be informative. Note that none of the three are identified as to the railroad which printed them.

A couple of Pacific Fruit Express cards are also interesting in that they inform crews about how the car is set up (heaters installed though car is empty, or half-stage grates enabled), and may have been on the auxiliary placard board alongside the car door, rather than on the route card board.

That auxiliary board is the smaller of the two to the left of the door on this InterMountain model of a Class R-40-10 car repainted into the 1950 paint scheme (the post-1945 paint schemes were reviewed in previous posts, this one at this link: http://modelingthesp.blogspot.com/2016/06/pfe-lettering-post-ww-ii-part-2.html ). This car has its route card board on the bolster end at left, and as you can see, a small rectangle of paper has been used to represent the presence of a card. A second card is on the auxiliary board near the door.

Finally, an interesting shipper card from Shell Oil, simply describing the cargo. There would also have been a “flammable” placard, but this card, likely stapled on the edge of a wood running board, would further inform switch crews as to the cargo. It’s even an elongated shape suitable for that location.

Some additional route cards, somewhat reminiscent of those in the previous post about these cards, are shown below. The one on the left has such faded pencil marks, nothing can be read, while the middle one likewise contains almost no information beyond what is printed, and the rubber stamped “RUSH.” The one on the right might be a Cotton Belt card used at Valley Junction, or it might be some other road’s card directing cars to the Cotton Belt.

These cards offer further illustrations of the range of prototype route cards, and I will continue with more of them in future posts.

Tony Thompson

Here are a few evidently used on outgoing cars from a shipper or yard. It appears that they describe needed actions (weigh, ice) or the cargo on board (lumber). These of course are not destination cards except in the sense that weighing the car, or icing it, might be the first things before departure. The lumber card may describe a cargo with special needs, or may simply be informative. Note that none of the three are identified as to the railroad which printed them.

A couple of Pacific Fruit Express cards are also interesting in that they inform crews about how the car is set up (heaters installed though car is empty, or half-stage grates enabled), and may have been on the auxiliary placard board alongside the car door, rather than on the route card board.

That auxiliary board is the smaller of the two to the left of the door on this InterMountain model of a Class R-40-10 car repainted into the 1950 paint scheme (the post-1945 paint schemes were reviewed in previous posts, this one at this link: http://modelingthesp.blogspot.com/2016/06/pfe-lettering-post-ww-ii-part-2.html ). This car has its route card board on the bolster end at left, and as you can see, a small rectangle of paper has been used to represent the presence of a card. A second card is on the auxiliary board near the door.

Finally, an interesting shipper card from Shell Oil, simply describing the cargo. There would also have been a “flammable” placard, but this card, likely stapled on the edge of a wood running board, would further inform switch crews as to the cargo. It’s even an elongated shape suitable for that location.

Some additional route cards, somewhat reminiscent of those in the previous post about these cards, are shown below. The one on the left has such faded pencil marks, nothing can be read, while the middle one likewise contains almost no information beyond what is printed, and the rubber stamped “RUSH.” The one on the right might be a Cotton Belt card used at Valley Junction, or it might be some other road’s card directing cars to the Cotton Belt.

These cards offer further illustrations of the range of prototype route cards, and I will continue with more of them in future posts.

Tony Thompson

Thursday, July 7, 2016

Parts storage vs, junk, Part 2

In the first post in this series, I showed a Jack Delano photo of a car repair track at Proviso Yard in Chicago, emphasizing the neatly stacked truck sideframes and bolsters that are visible in that photo. I went on to comment about ways to realistically model such sideframes (the post can be seen at: http://modelingthesp.blogspot.com/2016/06/prototype-parts-storage-vs-junk.html ). There is in fact more to say on the topic of parts storage versus junk piles, and I will continue in this post.

I wrote a post recently about the modeling of railroad wheels and wheelsets (it’s at: http://modelingthesp.blogspot.com/2016/04/truck-and-wheelset-modeling.html ). Wheels also are naturally stacked neatly when stored, and to accompany my modeling of sideframe and bolster storage (shown in the post cited at the top of the present post), I decided to add some stacks of wheels as well. A typical steel wheel for a 50-ton car weighs about 750 pounds, so these are not something a worker walks around with, but they do get stacked up in the vicinity of shops that do wheel truing or wheel replacement. The machine shop attached to the roundhouse in my layout town of Shumala might well have done wheel replacement, so stacks of wheels would make sense.

Model wheels could come from a variety of sources, the best being the Tichy set no. 3004, which comprises a whole lot of wheels and axles which are readily combined into wheelsets, as I showed in the post cited in the previous paragraph. But older model wheels can serve too. Even though they are the once-standard Code 110 ( meaning 0.110 inches thick), the excessive thickness is not as apparent in a stack or other mass of wheels. I no longer operate any car trucks with plastic wheels, so have an ample supply of old wheels. They are easily pulled off of steel axles, which I also don’t want to operate. I glued up some stacks, and painted them dark brown, with some rusty overtones like in the prototype photo in the linked post at the top of the present post. Then I glued them to scale 2 x 8-inch planks. Here are two of them, along with a single wheel (the ribbed wheels are old Train Miniature wheels.) These will reside alongside my roundhouse at Shumala, near the machine shop.

As I mentioned, all these wheels are the old-fashioned “Code 110” wheels, but you can see that in stacks like these it’s not as obvious.

Another part largely misunderstood by modelers is prototype couplers. They ordinarily have a rather short shank, as with the Gould coupler shown below. The shape of the butt end varies with manufacturer and type of draft yoke (the part in which the coupler rides and which is strongly connected to the center sill).

Another kind of coupler butt is shown by the ARA standard Type D coupler below, with a horizontal slot for the key attachment to the draft yoke.

I hope it is evident that having your HO scale shop storage area on the layout contain couplers with the shanks of Kadee or Accurail couplers will not exactly represent what you see above.

Digging around in old stuff in some parts boxes and drawers, I found a few dummy couplers from back in the day. Some are plastic, some are cast metal. Varney made the best one, but others made good representations too. In fact, the Varney dummy is so good looking that I and other modelers used to put them on contest models for the most realistic appearance. But any of these dummies make fine scenery, with the butt cut to a length like what you see above.

In the plastic coupler shank on the right, you can probably see the word “VARNEY” embossed. (You can click to enlarge.) I will have a group of five or six dummy couplers like this in my parts storage area near the roundhouse.

As mentioned in the first post in this series, I think having realistic parts stored is essential, whether wheels, sideframes, bolsters, couplers, or whatever. And they should be neatly stored, in my opinion, not heaped up in a jumble of mixed parts. The prototype usually stacked things neatly, and so should we.

Tony Thompson

I wrote a post recently about the modeling of railroad wheels and wheelsets (it’s at: http://modelingthesp.blogspot.com/2016/04/truck-and-wheelset-modeling.html ). Wheels also are naturally stacked neatly when stored, and to accompany my modeling of sideframe and bolster storage (shown in the post cited at the top of the present post), I decided to add some stacks of wheels as well. A typical steel wheel for a 50-ton car weighs about 750 pounds, so these are not something a worker walks around with, but they do get stacked up in the vicinity of shops that do wheel truing or wheel replacement. The machine shop attached to the roundhouse in my layout town of Shumala might well have done wheel replacement, so stacks of wheels would make sense.

Model wheels could come from a variety of sources, the best being the Tichy set no. 3004, which comprises a whole lot of wheels and axles which are readily combined into wheelsets, as I showed in the post cited in the previous paragraph. But older model wheels can serve too. Even though they are the once-standard Code 110 ( meaning 0.110 inches thick), the excessive thickness is not as apparent in a stack or other mass of wheels. I no longer operate any car trucks with plastic wheels, so have an ample supply of old wheels. They are easily pulled off of steel axles, which I also don’t want to operate. I glued up some stacks, and painted them dark brown, with some rusty overtones like in the prototype photo in the linked post at the top of the present post. Then I glued them to scale 2 x 8-inch planks. Here are two of them, along with a single wheel (the ribbed wheels are old Train Miniature wheels.) These will reside alongside my roundhouse at Shumala, near the machine shop.

As I mentioned, all these wheels are the old-fashioned “Code 110” wheels, but you can see that in stacks like these it’s not as obvious.

Another part largely misunderstood by modelers is prototype couplers. They ordinarily have a rather short shank, as with the Gould coupler shown below. The shape of the butt end varies with manufacturer and type of draft yoke (the part in which the coupler rides and which is strongly connected to the center sill).

Another kind of coupler butt is shown by the ARA standard Type D coupler below, with a horizontal slot for the key attachment to the draft yoke.

I hope it is evident that having your HO scale shop storage area on the layout contain couplers with the shanks of Kadee or Accurail couplers will not exactly represent what you see above.

Digging around in old stuff in some parts boxes and drawers, I found a few dummy couplers from back in the day. Some are plastic, some are cast metal. Varney made the best one, but others made good representations too. In fact, the Varney dummy is so good looking that I and other modelers used to put them on contest models for the most realistic appearance. But any of these dummies make fine scenery, with the butt cut to a length like what you see above.

In the plastic coupler shank on the right, you can probably see the word “VARNEY” embossed. (You can click to enlarge.) I will have a group of five or six dummy couplers like this in my parts storage area near the roundhouse.

As mentioned in the first post in this series, I think having realistic parts stored is essential, whether wheels, sideframes, bolsters, couplers, or whatever. And they should be neatly stored, in my opinion, not heaped up in a jumble of mixed parts. The prototype usually stacked things neatly, and so should we.

Tony Thompson

Monday, July 4, 2016

Route cards, Part 11 — examples

I have recently received a number of most interesting examples of prototype route cards, the small cards attached to freight cars by car clerks as an aid to yard crews or local train crews in clearly identifying destinations of cars. As I showed earlier (a post at: http://modelingthesp.blogspot.com/2012/01/route-cards-7.html ), the board on which route cards were placed was recommended to be no less than 5-1/2 x 9 inches and made of wood, so that route cards could be tacked or stapled to the board. These could be located on the side sill of open-top cars, on the door of box cars, and elsewhere as convenient. To repeat a photo used in a prior post about route cards, here is a clerk using a hammer stapler to attach a route card to a placard board (Cotton Belt photo). There is also a route card board on this car door, just visible behind the clerk’s face.

Just to illustrate in model form that route card boards could be located as railroads chose (as long as convenient for clerks), this SP GS gondola (an Ulrich model) has its route card board in the rightmost panel on the car side. This is known from photographs to be the prototype location on cars like this; to view an example of such a photo, see my previous post at: http://modelingthesp.blogspot.com/2011/11/route-cards-3.html .

Ralph Heiss was kind enough to send me a selection from his collection of route cards. As might be expected, these are immensely variable. They were not standardized, and each railroad or shipper made up whatever suited them. Moreover, railroad codes for yard tracks, switching districts, industrial spurs or door spots, interchange tracks, or outgoing trains were entirely at each road’s discretion.

Here are a number of examples, all with code numbers which might be outbound tracks, particular switching areas, or train identities. The one at upper right carries the Cotton Belt emblem, but none of the others are specifically identified. The other three do look like Santa Fe formats, as illustrated in a previous post describing Keith Jordan’s use of similar documents. (You can read that post at: http://modelingthesp.blogspot.com/2013/12/route-cards-8.html .) All are roughly 3-1/2 inches square, a common size for such cards. The upper left card was attached to UP 196136; the lower left card to PFE 60469; and the lower right to PFE 63387.

Note here, as on most route cards, that the car clerk has written with pencil the car reporting marks and number and sometimes other information (date, tonnage, contents, etc.)

Here is another group of these cards, also seeming to designate destination only by a code, though the one at far right is evidently for a particular train or class of train; on its “destination” line is stamped “Peoria-53.” The two at left are both Union Pacific tags, and the left card was attached to WAB 84162. The rightmost one was on M 25699.

The two UP cards are interesting in that the codes are in such bold type. Even in HO scale, it might be possible to reproduce lettering like this, or at least suggest it.

Finally, here are three additional interesting cards, The left one was attached to Southern 11990; the middle one is a Great Northern form and was on SAL 56524; and the right one, a UP form, to SL-SF 1313, obviously destined to Los Angeles. Use of other than black type is interesting, too.

To me, these are a fascinating insight into what car clerks did, and what switch crews had to work with. There are a bunch more of these which Ralph was kind enough to share. I will be showing examples of them in future posts.

Tony Thompson

Just to illustrate in model form that route card boards could be located as railroads chose (as long as convenient for clerks), this SP GS gondola (an Ulrich model) has its route card board in the rightmost panel on the car side. This is known from photographs to be the prototype location on cars like this; to view an example of such a photo, see my previous post at: http://modelingthesp.blogspot.com/2011/11/route-cards-3.html .

Ralph Heiss was kind enough to send me a selection from his collection of route cards. As might be expected, these are immensely variable. They were not standardized, and each railroad or shipper made up whatever suited them. Moreover, railroad codes for yard tracks, switching districts, industrial spurs or door spots, interchange tracks, or outgoing trains were entirely at each road’s discretion.

Here are a number of examples, all with code numbers which might be outbound tracks, particular switching areas, or train identities. The one at upper right carries the Cotton Belt emblem, but none of the others are specifically identified. The other three do look like Santa Fe formats, as illustrated in a previous post describing Keith Jordan’s use of similar documents. (You can read that post at: http://modelingthesp.blogspot.com/2013/12/route-cards-8.html .) All are roughly 3-1/2 inches square, a common size for such cards. The upper left card was attached to UP 196136; the lower left card to PFE 60469; and the lower right to PFE 63387.

Note here, as on most route cards, that the car clerk has written with pencil the car reporting marks and number and sometimes other information (date, tonnage, contents, etc.)

Here is another group of these cards, also seeming to designate destination only by a code, though the one at far right is evidently for a particular train or class of train; on its “destination” line is stamped “Peoria-53.” The two at left are both Union Pacific tags, and the left card was attached to WAB 84162. The rightmost one was on M 25699.

The two UP cards are interesting in that the codes are in such bold type. Even in HO scale, it might be possible to reproduce lettering like this, or at least suggest it.

Finally, here are three additional interesting cards, The left one was attached to Southern 11990; the middle one is a Great Northern form and was on SAL 56524; and the right one, a UP form, to SL-SF 1313, obviously destined to Los Angeles. Use of other than black type is interesting, too.

To me, these are a fascinating insight into what car clerks did, and what switch crews had to work with. There are a bunch more of these which Ralph was kind enough to share. I will be showing examples of them in future posts.

Tony Thompson

Friday, July 1, 2016

Reflections on layout visits

In this post, I want to offer a few thoughts about layout visits. Such visits may occur during open-house weekends, at model railroad conventions via bus or self-guided tours, or as part of operating weekends. Over the years, I have visited quite a lot of layouts in different parts of the country, and still have the feeling I recognized very early on, which is that I have never visited a single layout without getting at least one idea or seeing something clever, original or really well done. Even a “Plywood Pacific” may have intriguing track arrangements or operating wrinkles of interest.

Last March, I participated in the Soundrail operating weekend in the Seattle area (and posted a brief description of some of the activities, which you can read at this link: http://modelingthesp.blogspot.com/2016/03/soundrail-2016.html ). In that post, I showed a photograph of a nicely done scenic detail on Roger Nulton’s layout, which really struck me as to how nicely observed and rendered it was. Also, I mentioned there the outstanding N scale layout of Jim Youngkins, and I saw a lot of terrific ideas that Jim has implemented on his layout. I will just show one of them here, an excellent schematic town map, on the fascia right at the town location, as an aid to switch crews. This does take up some fascia area, but is a great way to supply information. (You can click on the image to enlarge it.)

It is always interesting, too, to observe the layout owner or host during such events, and to see how much and what kind of information about the layout is provided. Sometimes it is a multi-page handout, a timetable, or set of operating instructions; sometimes a single page; or it may be only verbal. Of course layouts vary in how complex is the intent, and how advanced is construction or experience with operating sessions.

A year ago, my friend Paul Weiss, who has operated on my layout a few times, made an entertaining but, I think, perceptive comment on this topic (you can read his comment below this post about operating sessions: http://modelingthesp.blogspot.com/2015/07/an-operating-weekend.html ). With Paul’s permission, I am going to expand a little on his remarks. He alluded to the common observation that for layout hosts, “when a layout is 80 percent scenicked, guests perceive it to be mostly done. And yet the host seems to feel it is less than half way there and kind of apologizes for what he perceives as 65 percent incompleteness. This could be termed the Host Incompleteness Perception, manifested, for example, as a single cardboard mockup building seeming (to the host) to block the dozens of scratchbuilt beauties nearby . . . but not really.”

Paul also mentioned another syndrome that one may experience at operating sessions, what he termed “Host Flaw Hysteria,” in which even the most minor difficulty is perceived by the host as towering above the many aspects of the layout which do work and work well. The visiting operator naturally sees it the other way around. But Host Flaw Hysteria can work to advantage in motivating the host to be sure to correct, or at least minimize, those flaws before the next session.

Paul also wisely observed that “the fun for guest operators can be directly a function of the humor, grace, and humility of the host. The very inconsequential problems that may bubble up create fodder for tiny jokes and trigger dialogue about potential causes and fixes. This dialogue, where the collective experience of the guests may happen to complement that of the host, leads to good ideas sometimes. The gracious host, always eager to learn more, encourages this and has fun with it. It makes the session very rich indeed.” I have seen the same climate develop at a number of operating sessions in which I was privileged to participate, and entirely agree with Paul about the outcome.

I guess I continue to struggle with Host Flaw Hysteria, but am making progress on Host Incompleteness Perception. I don’t know what percentage of “completeness” I would assign to my layout, but nearly all track is installed and working, and a lot of scenery is done, along with most of the needed buildings. This photo at Shumala on my layout shows a reasonably complete scene, even though the host knows there are few things remaining to be done. This is the Surf turn doing some switching, behind an RSD-5 on this day.

Layout visits, whether just for viewing or for operating, can be instructive as well as simply fun to look at. Look more closely and you will find any number of interesting and thought-provoking aspects to any layout. I enjoy learning from such visits, and expect to continue to do so.

Tony Thompson

Last March, I participated in the Soundrail operating weekend in the Seattle area (and posted a brief description of some of the activities, which you can read at this link: http://modelingthesp.blogspot.com/2016/03/soundrail-2016.html ). In that post, I showed a photograph of a nicely done scenic detail on Roger Nulton’s layout, which really struck me as to how nicely observed and rendered it was. Also, I mentioned there the outstanding N scale layout of Jim Youngkins, and I saw a lot of terrific ideas that Jim has implemented on his layout. I will just show one of them here, an excellent schematic town map, on the fascia right at the town location, as an aid to switch crews. This does take up some fascia area, but is a great way to supply information. (You can click on the image to enlarge it.)

It is always interesting, too, to observe the layout owner or host during such events, and to see how much and what kind of information about the layout is provided. Sometimes it is a multi-page handout, a timetable, or set of operating instructions; sometimes a single page; or it may be only verbal. Of course layouts vary in how complex is the intent, and how advanced is construction or experience with operating sessions.

A year ago, my friend Paul Weiss, who has operated on my layout a few times, made an entertaining but, I think, perceptive comment on this topic (you can read his comment below this post about operating sessions: http://modelingthesp.blogspot.com/2015/07/an-operating-weekend.html ). With Paul’s permission, I am going to expand a little on his remarks. He alluded to the common observation that for layout hosts, “when a layout is 80 percent scenicked, guests perceive it to be mostly done. And yet the host seems to feel it is less than half way there and kind of apologizes for what he perceives as 65 percent incompleteness. This could be termed the Host Incompleteness Perception, manifested, for example, as a single cardboard mockup building seeming (to the host) to block the dozens of scratchbuilt beauties nearby . . . but not really.”

Paul also mentioned another syndrome that one may experience at operating sessions, what he termed “Host Flaw Hysteria,” in which even the most minor difficulty is perceived by the host as towering above the many aspects of the layout which do work and work well. The visiting operator naturally sees it the other way around. But Host Flaw Hysteria can work to advantage in motivating the host to be sure to correct, or at least minimize, those flaws before the next session.

Paul also wisely observed that “the fun for guest operators can be directly a function of the humor, grace, and humility of the host. The very inconsequential problems that may bubble up create fodder for tiny jokes and trigger dialogue about potential causes and fixes. This dialogue, where the collective experience of the guests may happen to complement that of the host, leads to good ideas sometimes. The gracious host, always eager to learn more, encourages this and has fun with it. It makes the session very rich indeed.” I have seen the same climate develop at a number of operating sessions in which I was privileged to participate, and entirely agree with Paul about the outcome.

I guess I continue to struggle with Host Flaw Hysteria, but am making progress on Host Incompleteness Perception. I don’t know what percentage of “completeness” I would assign to my layout, but nearly all track is installed and working, and a lot of scenery is done, along with most of the needed buildings. This photo at Shumala on my layout shows a reasonably complete scene, even though the host knows there are few things remaining to be done. This is the Surf turn doing some switching, behind an RSD-5 on this day.

Layout visits, whether just for viewing or for operating, can be instructive as well as simply fun to look at. Look more closely and you will find any number of interesting and thought-provoking aspects to any layout. I enjoy learning from such visits, and expect to continue to do so.

Tony Thompson

Subscribe to:

Posts (Atom)