I have written in a number of previous posts about the Empty Car Bills of various railroads (see for example: http://modelingthesp.blogspot.com/2015/04/waybills-part-40-more-empty-car-bills.html ), and as time passes, more of these documents come to light. This post shows two interesting car slips from the Northern Pacific, sent to me in physical original form by Gary Wildung.

The first is yet another version of the Empty Car Bill, shown below. It combines the “home” routing with the “to load” routing, as do many examples of this type of document. And it seems designed for handwritten entries; the material is light card stock, about like a file folder. (You can click on the image to enlarge it.) The NP’s document date for this form is 8-51.

I also found it interesting that the NP used a Car Card for loaded cars, This is less commonly encountered among the railroad paper I have seen. It is intended for dispatch of cars for which the waybill has not yet been received, but which needs to move. It is dated 6-50.

Interestingly, the instructions at the bottom explain that the slip

should accompany the car to destination, and that the waybill, when

prepared, will be sent separately to the agent at destination. Here is a larger image of those instructions:

This document is a quite logical approach to moving a “hot” car when for some reason the waybill is not ready. I have not seen anything exactly like this for other railroads, but it could serve as an abbreviated waybill for those modelers who do not wish to make up full, detailed waybills, as there is less information required. Of course, if you used only these slips, visitors could wonder why none of the agents on the railroad could prepare a timely waybill. <grin>

Thanks to Gary for making these interesting car slips available. They may give those interested in model layout operation some idea for document design.

Tony Thompson

Wednesday, December 30, 2015

Sunday, December 27, 2015

Modeling an insulated tank car, Part 2

In the previous post (see: http://modelingthesp.blogspot.com/2015/12/modeling-insulated-tank-car.html ), I described the model I wished to build, and showed a photo of the Mathieson prototype car I wanted to use as a guide. At the end of that post, I had completed modeling of the new expansion dome and surrounding details. I then finished body work by adding grab irons at each corner of the tank, with 0.010-inch brass wire.

With Athearn tank cars, I usually decide whether to replace the handrail supports (that are molded onto the car body) on the basis of the final body color. If the body will be black or a dark color, those Athearn supports are not very visible and are acceptable to me. But if the body will be a light color, the clumsiness of the Athearn feature is all too evident, and then I remove those supports and replace them with Precision Scale brass ones (their part no. 32110). The brass parts are more work but look hugely better — if they will be seen. The car being modeled here will have a dark green upper body, so I did not replace the Athearn supports.

The Athearn handrails supplied nowadays are not too oversize, though back in the day these were quite big. They used to be 0.029 inches in diameter; now they are about 0.023 inches, a 20 percent decrease and an improvement in appearance. But they are still oversize. Nearly all prototype tank car handrails were made from 1-1/4-inch iron pipe. That “nominal” pipe size, as it is known, can be seen in any lookup table to be 1.66 inches outside diameter, which in turn converts to exactly 0.019 inches in HO scale. Here again, on a light-color tank body, I would replace the oversize handrail, but on a dark body like my model will have, I will retain the Athearn wire parts.

If the Athearn handrails are retained, then the question of replacing the Athearn ladders arises. Again, if they end up a dark color, they look all right. The one thing they do need is have the top filed flat, as the “bulges” of the Athearn design look quite odd and certainly not prototypical. This is a 10-second job, to go from the left ladder to the right-hand one:

My next step was to attach ladders and handrails, then airbrush the entire upper body Dark Green, while the lower body is black. The ladders then need to be touched up as black (see the prototype photo in the prior post) below the level of the bottom sheet, which is just visible here.

The body is ready for decals. In my decal stash I had Champ sets HT-211 (Mathieson) and HT-70 and -71 (GATX and SHPX). The Mathieson set had the MAWX reporting marks used on a minority of Mathieson cars, but most were leased from SHPX, so I decided to use those reporting marks. The GATX set supplied basic data for a car built by General American (the Athearn underframe is a GA design). For locating details, see the prototype photo in the prior post.

Meanwhile, I carried out my usual upgrades to the Athearn underframe. I separated the draft gear box covers from the rest of the Athearn center sill, and drilled and tapped the lid, and the center post in each coupler box, for a 2-56 screw. The brake gear is reasonably well located, but the parts of the brake rigging which extend to the trucks are not represented. I usually add wire or styrene rod. On this model, I used white Plastruct 0.015-inch styrene rod, as can be seen here. No piping has been added yet.

Also, provision must be made for a vertical-staff handbrake. For this, I usually fill the locating hole in the Athearn underframe with the Athearn handbrake stand, then cut it off flush with the deck. Then I drill for a brass wire staff and add a Tichy or other appropriate brake wheel. I also apply the Athearn placard boards, though they are oversize, because they are steel stampings and thus sturdy. When I glue a correct-size placard to them, the black border isn’t too obvious.

The assembled and lettered car is shown in the photo below. It still needs weathering, which I will do fairly lightly to indicate a recent coat of paint. A few chalk marks were added; placards will be attached after weathering. (You can click to enlarge.)

The trucks are Athearn with Reboxx wheelsets (I think the 0.088-inch wheel treads are essential on a model that has the wheels as visible as a tank car), and the couplers are Kadee #158.

This car makes an interesting addition to my fleet of insulated tank cars, though it would be a much more common car type if shortened to 10,000-gallon size, as I did in the Warren car I mentioned in the previous post. I plan to make another of the shortened cars in a future project.

Tony Thompson

With Athearn tank cars, I usually decide whether to replace the handrail supports (that are molded onto the car body) on the basis of the final body color. If the body will be black or a dark color, those Athearn supports are not very visible and are acceptable to me. But if the body will be a light color, the clumsiness of the Athearn feature is all too evident, and then I remove those supports and replace them with Precision Scale brass ones (their part no. 32110). The brass parts are more work but look hugely better — if they will be seen. The car being modeled here will have a dark green upper body, so I did not replace the Athearn supports.

The Athearn handrails supplied nowadays are not too oversize, though back in the day these were quite big. They used to be 0.029 inches in diameter; now they are about 0.023 inches, a 20 percent decrease and an improvement in appearance. But they are still oversize. Nearly all prototype tank car handrails were made from 1-1/4-inch iron pipe. That “nominal” pipe size, as it is known, can be seen in any lookup table to be 1.66 inches outside diameter, which in turn converts to exactly 0.019 inches in HO scale. Here again, on a light-color tank body, I would replace the oversize handrail, but on a dark body like my model will have, I will retain the Athearn wire parts.

If the Athearn handrails are retained, then the question of replacing the Athearn ladders arises. Again, if they end up a dark color, they look all right. The one thing they do need is have the top filed flat, as the “bulges” of the Athearn design look quite odd and certainly not prototypical. This is a 10-second job, to go from the left ladder to the right-hand one:

My next step was to attach ladders and handrails, then airbrush the entire upper body Dark Green, while the lower body is black. The ladders then need to be touched up as black (see the prototype photo in the prior post) below the level of the bottom sheet, which is just visible here.

The body is ready for decals. In my decal stash I had Champ sets HT-211 (Mathieson) and HT-70 and -71 (GATX and SHPX). The Mathieson set had the MAWX reporting marks used on a minority of Mathieson cars, but most were leased from SHPX, so I decided to use those reporting marks. The GATX set supplied basic data for a car built by General American (the Athearn underframe is a GA design). For locating details, see the prototype photo in the prior post.

Meanwhile, I carried out my usual upgrades to the Athearn underframe. I separated the draft gear box covers from the rest of the Athearn center sill, and drilled and tapped the lid, and the center post in each coupler box, for a 2-56 screw. The brake gear is reasonably well located, but the parts of the brake rigging which extend to the trucks are not represented. I usually add wire or styrene rod. On this model, I used white Plastruct 0.015-inch styrene rod, as can be seen here. No piping has been added yet.

Also, provision must be made for a vertical-staff handbrake. For this, I usually fill the locating hole in the Athearn underframe with the Athearn handbrake stand, then cut it off flush with the deck. Then I drill for a brass wire staff and add a Tichy or other appropriate brake wheel. I also apply the Athearn placard boards, though they are oversize, because they are steel stampings and thus sturdy. When I glue a correct-size placard to them, the black border isn’t too obvious.

The assembled and lettered car is shown in the photo below. It still needs weathering, which I will do fairly lightly to indicate a recent coat of paint. A few chalk marks were added; placards will be attached after weathering. (You can click to enlarge.)

The trucks are Athearn with Reboxx wheelsets (I think the 0.088-inch wheel treads are essential on a model that has the wheels as visible as a tank car), and the couplers are Kadee #158.

This car makes an interesting addition to my fleet of insulated tank cars, though it would be a much more common car type if shortened to 10,000-gallon size, as I did in the Warren car I mentioned in the previous post. I plan to make another of the shortened cars in a future project.

Tony Thompson

Thursday, December 24, 2015

Modeling a gas station

I have written in numerous prior posts about oil companies, bulk oil dealers, and the tank cars owned by the oil companies. You can readily find those posts in the archive of this blog, by putting the desired key word into the search box directly to the right on this page. But I also wanted to show the retail side of this topic on my layout.

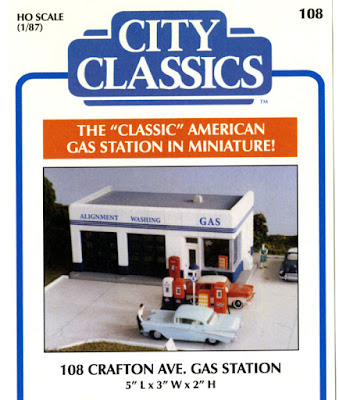

I have always planned to have a period gas station (or service station, if you will) on the layout. There have been plenty of gas station kits over the years, and many prototype stations were simple enough that they could be scratchbuilt without too much exertion. But there is an excellent gas station kit made by City Classics, which I especially like because when I lived in Pittsburgh, I knew City Classics’ proprietor, Jim Sacco, pretty well. That made me want to build that kit. It represents a “Moderne” style building, on which porcelain-enamel steel panels covered the building. The plain, glossy look led to structures of this style being called “iceboxes.”

Very properly, the kit comes in plain white, and you then need to decorate it. Each oil company had at least a general standard of color use, lettering, etc., though individual stations varied considerably in some cases. I immediately started looking on the Internet to see what I could find, for period decoration, and in fact there are a lot of photos out there. There is ample modeling information for almost any oil company chosen.

I decided I should choose one of the oil companies already represented on the layout by a bulk oil dealer. Among them is a Union 76 dealer, as I have described (see: http://modelingthesp.blogspot.com/2015/09/modeling-union-oil-dealer-part-2.html ). When I was a teenager, I tended to fill up at the Union 76 station near my home, so I naturally leaned toward doing the City Classics kit as a Union station. Here is a photo from the Phillips 66 website (the current owner of Union’s brand names), and it shows both the paint colors of gas pumps, and the use of orange on the building. It’s a large and more modern building, but shows the decoration theme. Pumps are white with blue on the sides. Other Union photos show orange used for a ground-level stripe around buildings, and in one case doors in the station were orange.

Another image found on the web is an older station, probably a one-off design, but of interest for its paint scheme. It was located in Big Bear, California.

Just for background, Union Oil, founded in 1890, created its “76” brand in 1932, and continued in the consumer marketing business until all retail operations were sold in 1997 to Tosco, which in turn was acquired by Phillips, which became ConocoPhillips in 2002. In 2012, ConocoPhillips split into two companies, one of which, renamed Phillips 66, carries out consumer marketing, and uses the “76” brand today (though they have replaced the distinctive Union orange with red). Union’s corporate parent since 1983 was Unocal Corp., which continued oil production and refining after the sale of its marking division to Tosco, and was acquired in 2005 by Chevron.

So I had a clear idea of some paint scheme and decoration ideas, which would be easy to adapt to the City Classics kit. Even the pumps in the kit wold be easy to model, matching the ones in the upper photo here. I acquired some round orange “76” emblems on the web and tried printing them out at small sizes, to use on gas pumps as well as on the building itself.

The subject of gas pumps led to thinking about related issues, such as the price of gasoline in my modeling year of 1953. I suppose it’s no surprise that prices for past years are readily found on the Internet. I used this site: http://www.fiftiesweb.com/pop/prices-1953.htm , and learned that gas cost about 22 cents a gallon in 1953. It’s not an idle curiosity, by the way, since in that day gas prices were often prominently advertised at stations, and I want to do the same. The City Classics kit includes a curbside sign for regular gas at 23 cents a gallon, perfect for me.

With this research under my belt, I am now starting work on my City Classics filling station kit, to be branded as a Union 76 station. More later.

Tony Thompson

I have always planned to have a period gas station (or service station, if you will) on the layout. There have been plenty of gas station kits over the years, and many prototype stations were simple enough that they could be scratchbuilt without too much exertion. But there is an excellent gas station kit made by City Classics, which I especially like because when I lived in Pittsburgh, I knew City Classics’ proprietor, Jim Sacco, pretty well. That made me want to build that kit. It represents a “Moderne” style building, on which porcelain-enamel steel panels covered the building. The plain, glossy look led to structures of this style being called “iceboxes.”

Very properly, the kit comes in plain white, and you then need to decorate it. Each oil company had at least a general standard of color use, lettering, etc., though individual stations varied considerably in some cases. I immediately started looking on the Internet to see what I could find, for period decoration, and in fact there are a lot of photos out there. There is ample modeling information for almost any oil company chosen.

I decided I should choose one of the oil companies already represented on the layout by a bulk oil dealer. Among them is a Union 76 dealer, as I have described (see: http://modelingthesp.blogspot.com/2015/09/modeling-union-oil-dealer-part-2.html ). When I was a teenager, I tended to fill up at the Union 76 station near my home, so I naturally leaned toward doing the City Classics kit as a Union station. Here is a photo from the Phillips 66 website (the current owner of Union’s brand names), and it shows both the paint colors of gas pumps, and the use of orange on the building. It’s a large and more modern building, but shows the decoration theme. Pumps are white with blue on the sides. Other Union photos show orange used for a ground-level stripe around buildings, and in one case doors in the station were orange.

Another image found on the web is an older station, probably a one-off design, but of interest for its paint scheme. It was located in Big Bear, California.

Just for background, Union Oil, founded in 1890, created its “76” brand in 1932, and continued in the consumer marketing business until all retail operations were sold in 1997 to Tosco, which in turn was acquired by Phillips, which became ConocoPhillips in 2002. In 2012, ConocoPhillips split into two companies, one of which, renamed Phillips 66, carries out consumer marketing, and uses the “76” brand today (though they have replaced the distinctive Union orange with red). Union’s corporate parent since 1983 was Unocal Corp., which continued oil production and refining after the sale of its marking division to Tosco, and was acquired in 2005 by Chevron.

So I had a clear idea of some paint scheme and decoration ideas, which would be easy to adapt to the City Classics kit. Even the pumps in the kit wold be easy to model, matching the ones in the upper photo here. I acquired some round orange “76” emblems on the web and tried printing them out at small sizes, to use on gas pumps as well as on the building itself.

The subject of gas pumps led to thinking about related issues, such as the price of gasoline in my modeling year of 1953. I suppose it’s no surprise that prices for past years are readily found on the Internet. I used this site: http://www.fiftiesweb.com/pop/prices-1953.htm , and learned that gas cost about 22 cents a gallon in 1953. It’s not an idle curiosity, by the way, since in that day gas prices were often prominently advertised at stations, and I want to do the same. The City Classics kit includes a curbside sign for regular gas at 23 cents a gallon, perfect for me.

With this research under my belt, I am now starting work on my City Classics filling station kit, to be branded as a Union 76 station. More later.

Tony Thompson

Monday, December 21, 2015

Modeling an insulated tank car

I have written in several places, and mentioned in many clinics, that the Athearn “chemical” tank car has some serious drawbacks as it comes from the box. Most recently, I showed a correction of the two most visible problems, the considerably oversize valve bonnet and the equally large platform around the bonnet, in a post about a Hooker ICC-105 tank car (that post is at this link: http://modelingthesp.blogspot.com/2015/05/another-approach-to-tank-car-platforms.html ).

But the body itself is a well-rendered insulated tank car body, of about 11,000 gallons size. That is large for most liquid cargoes of the transition era, but all right for pressurized gases such as propane or ammonia. The Athearn bottom sheet for the tank is the same one used on their riveted three-compartment tank car, and thus has to be stripped of its rivets; likewise the underframe was designed for that same three-compartment car, and has to have the triple outlets and other features removed. But these changes are quick and easy.

What then can be done with this model, beyond the ICC 105 conversions of the kind shown in the post cited in the first paragraph? Two can be mentioned. One is to shorten the tank, thus reducing its gallonage into the range of most tank cars of the transition era. I described building an ICC-104 Warren Petroleum car that way, in an earlier post (you can see it at: http://modelingthesp.blogspot.com/2011/06/tank-car-modeling.html ), and in an article in the July 2011 issue of Railroad Model Craftsman. That car received a scratchbuilt expansion dome.

The second possibility is to forego the insulated dome, as was added to my Warren car just mentioned, and instead add an uninsulated dome. Photos show that this was not an uncommon arrangement, likely for cargoes less sensitive to temperature variation, and thus these cars were usually insulated ICC 103 cars (AAR class TMI), with lower pressure settings than most ICC 104 cars. And a very nice dome of this kind is provided in the Tichy Tank Car Detail Set, their number 3007. It happens to have the correct base radius for the Athearn insulated tank, as you can see in the photo below. Obviously that oversize Athearn valve bonnet and associated details were removed first.

The 1960s Dow lettering will be stripped off before painting The dome-top details from the Tichy set have not yet been added.

My goal here was a Mathieson Chemical tank car of 10,500-gallon size, pretty close to the Athearn tank, and in the form of an insulated ICC-103, that is, a low-pressure general-service tank car. Some Mathieson insulated cars had dome platforms, some did not, but without doubt the most common arrangement with cars like this is just a short walkway on each side of the dome. To see many examples of pre-1955 tank cars, see Edward S. Kaminski, Tank Cars, American Car & Foundry Company, 1865 to 1955, Signature Press, Berkeley and Wilton, California, 2003. Here is a Mathieson car similar to what I was aiming at (AC&F photo, courtesy Ed Kaminski). It is an insulated ICC 103, built in 1938, and is somewhat smaller than my model would be.

Close examination of the paint scheme on this car shows that the bottom sheet of the insulated jacket is black, the upper part and ends a slightly lighter color. Mathieson in those years used a medium to dark green for many of their cars, and I believe the upper part in the photo is that color.

The Mathieson car had grab irons on each side of the dome, as seen in the photo above. I added these using 0.012-inch brass wire, and also attached the Tichy dome-top details. Note that the paint has been sanded off below the dome, in preparation for attaching the dome walks.

The car I wanted to model would have been built before 1948 (when platforms and running boards were first required to be steel). Thus I needed to model the dome walkways as wood planks. Here is how I did that. With about three scale feet of scale 4 x 4-inch styrene, filed on one corner at about 45 degrees, to match the slant of the tank, I created a support for the walk. This was glued to the tank fairly high on the side, almost at the base of the dome, as suggested by the Mathieson photo above.

The prototype dome walk (see Mathieson photo) is about the length of the dome diameter, that is to say, about five scale feet. I used a scale 1 x 8-inch piece of styrene, though a thicker piece could be used. This was glued to the shorter 4 x 4 support mentioned above. In the photo below, you see one walk installed, with the 4 x 4 support piece visible on the other side.

Finally, each dome walk should have a grab iron at its edge, as is visible in the Mathieson photo above, and diagonal supports. As shown below, I made the grab irons from 0.010-inch brass wire and secured them in place below the walk with CA, then made the diagonal supports from scale 1 x 3-inch styrene strips about 8 scale inches long.

At this point I will pause in describing the model construction. Next will come a few other details, all of which comprise simple and straightforward steps. They will be followed by painting and by work on the kit underframe. I will show those steps in a following post.

I close with a small personal note, as today is December 21, the shortest day. All through my youth, I always noticed that my dad welcomed this date, because now the days would be getting longer. I wrote about that a few years ago (see: http://modelingthesp.blogspot.com/2012/12/the-shortest-day.html ), and quoted, with warm permission, a wonderful poem on the subject by Susan Cooper. Enjoy.

Tony Thompson

But the body itself is a well-rendered insulated tank car body, of about 11,000 gallons size. That is large for most liquid cargoes of the transition era, but all right for pressurized gases such as propane or ammonia. The Athearn bottom sheet for the tank is the same one used on their riveted three-compartment tank car, and thus has to be stripped of its rivets; likewise the underframe was designed for that same three-compartment car, and has to have the triple outlets and other features removed. But these changes are quick and easy.

What then can be done with this model, beyond the ICC 105 conversions of the kind shown in the post cited in the first paragraph? Two can be mentioned. One is to shorten the tank, thus reducing its gallonage into the range of most tank cars of the transition era. I described building an ICC-104 Warren Petroleum car that way, in an earlier post (you can see it at: http://modelingthesp.blogspot.com/2011/06/tank-car-modeling.html ), and in an article in the July 2011 issue of Railroad Model Craftsman. That car received a scratchbuilt expansion dome.

The second possibility is to forego the insulated dome, as was added to my Warren car just mentioned, and instead add an uninsulated dome. Photos show that this was not an uncommon arrangement, likely for cargoes less sensitive to temperature variation, and thus these cars were usually insulated ICC 103 cars (AAR class TMI), with lower pressure settings than most ICC 104 cars. And a very nice dome of this kind is provided in the Tichy Tank Car Detail Set, their number 3007. It happens to have the correct base radius for the Athearn insulated tank, as you can see in the photo below. Obviously that oversize Athearn valve bonnet and associated details were removed first.

The 1960s Dow lettering will be stripped off before painting The dome-top details from the Tichy set have not yet been added.

My goal here was a Mathieson Chemical tank car of 10,500-gallon size, pretty close to the Athearn tank, and in the form of an insulated ICC-103, that is, a low-pressure general-service tank car. Some Mathieson insulated cars had dome platforms, some did not, but without doubt the most common arrangement with cars like this is just a short walkway on each side of the dome. To see many examples of pre-1955 tank cars, see Edward S. Kaminski, Tank Cars, American Car & Foundry Company, 1865 to 1955, Signature Press, Berkeley and Wilton, California, 2003. Here is a Mathieson car similar to what I was aiming at (AC&F photo, courtesy Ed Kaminski). It is an insulated ICC 103, built in 1938, and is somewhat smaller than my model would be.

Close examination of the paint scheme on this car shows that the bottom sheet of the insulated jacket is black, the upper part and ends a slightly lighter color. Mathieson in those years used a medium to dark green for many of their cars, and I believe the upper part in the photo is that color.

The Mathieson car had grab irons on each side of the dome, as seen in the photo above. I added these using 0.012-inch brass wire, and also attached the Tichy dome-top details. Note that the paint has been sanded off below the dome, in preparation for attaching the dome walks.

The car I wanted to model would have been built before 1948 (when platforms and running boards were first required to be steel). Thus I needed to model the dome walkways as wood planks. Here is how I did that. With about three scale feet of scale 4 x 4-inch styrene, filed on one corner at about 45 degrees, to match the slant of the tank, I created a support for the walk. This was glued to the tank fairly high on the side, almost at the base of the dome, as suggested by the Mathieson photo above.

The prototype dome walk (see Mathieson photo) is about the length of the dome diameter, that is to say, about five scale feet. I used a scale 1 x 8-inch piece of styrene, though a thicker piece could be used. This was glued to the shorter 4 x 4 support mentioned above. In the photo below, you see one walk installed, with the 4 x 4 support piece visible on the other side.

Finally, each dome walk should have a grab iron at its edge, as is visible in the Mathieson photo above, and diagonal supports. As shown below, I made the grab irons from 0.010-inch brass wire and secured them in place below the walk with CA, then made the diagonal supports from scale 1 x 3-inch styrene strips about 8 scale inches long.

At this point I will pause in describing the model construction. Next will come a few other details, all of which comprise simple and straightforward steps. They will be followed by painting and by work on the kit underframe. I will show those steps in a following post.

I close with a small personal note, as today is December 21, the shortest day. All through my youth, I always noticed that my dad welcomed this date, because now the days would be getting longer. I wrote about that a few years ago (see: http://modelingthesp.blogspot.com/2012/12/the-shortest-day.html ), and quoted, with warm permission, a wonderful poem on the subject by Susan Cooper. Enjoy.

Tony Thompson

Friday, December 18, 2015

Waybill posts collected

After the first two years of my posting to this blog about waybill topics, including a description of model waybills and how I make and use them, Mike White contacted me to ask if he could collect the entire set into a single PDF for convenience of those who might like to have everything in one piece. The only changes Mike wanted to make was to eliminate some minor overlaps among posts. I was happy for him to do so, and that PDF of Mike’s went onto Google Drive on February 22, 2013. It represented the first 26 posts in a series each labeled as a “Waybill Part” as well as a couple of posts about operation. Altogether, it totals 73 pages. That PDF is still available under the name Waybill Collection on Google Drive or through this post: http://modelingthesp.blogspot.com/2013/02/waybills-27-collected-posts.html .

But since that time, almost three years ago, I have continued to post about waybill topics and related model operation topics. Mike has been observing that fact, and recently contacted me for permission to once again collect all those waybill posts, not only the first 26 but a number of more recent ones, up to Waybills, Part 45 posted just last week, and also a few operating-topic posts related to waybills. Again, I readily consented, and the resulting PDF, more complete and extensive than the first one, is now available to anyone for viewing, downloading or printing, at the following link to Google Drive:

https://drive.google.com/open?id=0Bz_ctrHrDz4wVld1d0N4NUU3T3M

Small note of caution, should you wish to download: the file is fairly large, now 126 pages, and about 9 MB, and accordingly may strain some people’s computer system. But you can certainly read it at Google Drive without downloading, if you wish. And any particular post within the PDF can be viewed in the usual way here among the blog site collection, simply by searching the blog (using the search box at the top right of this page), under the search term of the particular post name.

The other option would be to download only the posts since Part 26 (where that first PDF ended), in other words, just download the added posts since the original Collection. A PDF of just those posts, starting with Part 27, is about 4.4 MB and is also available on Google Drive, at this link:

https://drive.google.com/open?id=0Bz_ctrHrDz4wRHYydktSN1F5Y0E

In that connection, the original PDF of the first 26 waybill posts, and some allied posts, is still available at this link:

https://drive.google.com/open?id=0Bz_ctrHrDz4wZlBiSmJpb3YwaFE

I can also send any of the three files directly to anyone wishing to receive them, via Hightail or Dropbox or other file sharing application if you wish. Contact me directly if you prefer that option.

All in all, I think Mike has done the community a service in collecting the posts this way, and I thank him for the effort. I hope some of you will find it useful.

Tony Thompson

But since that time, almost three years ago, I have continued to post about waybill topics and related model operation topics. Mike has been observing that fact, and recently contacted me for permission to once again collect all those waybill posts, not only the first 26 but a number of more recent ones, up to Waybills, Part 45 posted just last week, and also a few operating-topic posts related to waybills. Again, I readily consented, and the resulting PDF, more complete and extensive than the first one, is now available to anyone for viewing, downloading or printing, at the following link to Google Drive:

https://drive.google.com/open?id=0Bz_ctrHrDz4wVld1d0N4NUU3T3M

Small note of caution, should you wish to download: the file is fairly large, now 126 pages, and about 9 MB, and accordingly may strain some people’s computer system. But you can certainly read it at Google Drive without downloading, if you wish. And any particular post within the PDF can be viewed in the usual way here among the blog site collection, simply by searching the blog (using the search box at the top right of this page), under the search term of the particular post name.

The other option would be to download only the posts since Part 26 (where that first PDF ended), in other words, just download the added posts since the original Collection. A PDF of just those posts, starting with Part 27, is about 4.4 MB and is also available on Google Drive, at this link:

https://drive.google.com/open?id=0Bz_ctrHrDz4wRHYydktSN1F5Y0E

In that connection, the original PDF of the first 26 waybill posts, and some allied posts, is still available at this link:

https://drive.google.com/open?id=0Bz_ctrHrDz4wZlBiSmJpb3YwaFE

I can also send any of the three files directly to anyone wishing to receive them, via Hightail or Dropbox or other file sharing application if you wish. Contact me directly if you prefer that option.

All in all, I think Mike has done the community a service in collecting the posts this way, and I thank him for the effort. I hope some of you will find it useful.

Tony Thompson

Tuesday, December 15, 2015

Waybills, Part 45: preferred movement bills

Among the numerous waybill forms standardized by the AAR was one for “preferred movement,” and that bill is my topic for today. The usual standard waybill, the “general-service” bill, as it were, was AAR Form AD-98, and is familiar to most modelers through a variety of sources. Its use was mandatory, and it was to be printed on white paper. I have shown a typical blank waybill of this type (see: http://modelingthesp.blogspot.com/2012/02/waybills-18-resources.html ) and have also shown the process by which I modified the prototype form to achieve a compacted model version (you can read that post at: http://modelingthesp.blogspot.com/2011/02/waybills-4.html ).

There was also a livestock form (AAR Standard Form AD-101), printed on white stock, also a mandatory form, and a perishable form (AAR Standard Form AD-113), printed on pink stock, which was a recommended form. These were pretty much the principal forms which modelers need to recognize. But my topic here is an additional interesting one, the preferred-movement bill.

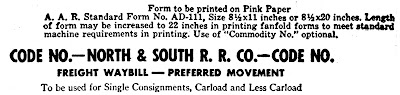

In essence, this waybill form, AAR Standard Form AD-111, was intended to be used for priority cargoes, and use of a different form was supposed to identify these shipments to clerks and others who might handle the waybill and assign priority outbound trains. It can be regarded as a “rush” waybill. Like the perishable form, Form 111 was a recommended, not mandatory, form, and is stated to be printed on pink stock.

The body of the form is not as important as the header, which was slightly different than for other forms, as shown below. This is just the top of the form, with the AAR Form info shown above it (all standard forms are shown with this sort of dimensional recommendations).

Note the railroad name arrangement, flanked at both ends by the AAR code number. I have put the complete AAR list of those railroad code numbers on Google Drive, as you can access from the post at the following link: http://modelingthesp.blogspot.com/2012/08/railway-accounting-code-numbers.html .

The Form 111 header above was scanned from the invaluable AAR publication, Railway Accounting Rules, which contains dozens of standard forms (and rules for using them, if you care about that aspect). I discussed that book in a previous post (see it at: http://modelingthesp.blogspot.com/2012/02/waybills-18-resources.html ); I use the 1950 edition of this book.

The body of this waybill was quite similar to the regular freight waybill, Form 98, differing only in minor aspects that I, for one, don’t feel the need to use as a modeler. So my own standard model waybill can be used as a “preferred movement” waybill just by changing the header, and of course printing it on pink stock.This will help operators on the layout identify the “hottest” cars for priority handling, just as it did on the prototype.

To show some examples, I have used foodstuffs directed to the wholesale grocer on my layout, Peerless Foods, and a shipment of parts vital to a time-critical item of production. at Jupiter Pump & Compressor. I suppose almost any cargo could be shipped under a “rush” order, but railroaders have told me that these kinds of waybills were not common, so I am only making a few. (You can click on the image to enlarge, if you wish.)

One of these is a food waybill, understandable as a preferred movement, but the other is chosen to represent urgently needed parts for production. The one on the right has a pencil notation on it, as I add to many bills, as a partial representation of the very common handwriting additions and corrections to prototype waybills.

These preferred-movement bills will add some variety to my waybill operation, and will serve, as does the occasional LCL waybill marked “stop this car at . . .”, to keep crews on their toes.

Tony Thompson

There was also a livestock form (AAR Standard Form AD-101), printed on white stock, also a mandatory form, and a perishable form (AAR Standard Form AD-113), printed on pink stock, which was a recommended form. These were pretty much the principal forms which modelers need to recognize. But my topic here is an additional interesting one, the preferred-movement bill.

In essence, this waybill form, AAR Standard Form AD-111, was intended to be used for priority cargoes, and use of a different form was supposed to identify these shipments to clerks and others who might handle the waybill and assign priority outbound trains. It can be regarded as a “rush” waybill. Like the perishable form, Form 111 was a recommended, not mandatory, form, and is stated to be printed on pink stock.

The body of the form is not as important as the header, which was slightly different than for other forms, as shown below. This is just the top of the form, with the AAR Form info shown above it (all standard forms are shown with this sort of dimensional recommendations).

Note the railroad name arrangement, flanked at both ends by the AAR code number. I have put the complete AAR list of those railroad code numbers on Google Drive, as you can access from the post at the following link: http://modelingthesp.blogspot.com/2012/08/railway-accounting-code-numbers.html .

The Form 111 header above was scanned from the invaluable AAR publication, Railway Accounting Rules, which contains dozens of standard forms (and rules for using them, if you care about that aspect). I discussed that book in a previous post (see it at: http://modelingthesp.blogspot.com/2012/02/waybills-18-resources.html ); I use the 1950 edition of this book.

The body of this waybill was quite similar to the regular freight waybill, Form 98, differing only in minor aspects that I, for one, don’t feel the need to use as a modeler. So my own standard model waybill can be used as a “preferred movement” waybill just by changing the header, and of course printing it on pink stock.This will help operators on the layout identify the “hottest” cars for priority handling, just as it did on the prototype.

To show some examples, I have used foodstuffs directed to the wholesale grocer on my layout, Peerless Foods, and a shipment of parts vital to a time-critical item of production. at Jupiter Pump & Compressor. I suppose almost any cargo could be shipped under a “rush” order, but railroaders have told me that these kinds of waybills were not common, so I am only making a few. (You can click on the image to enlarge, if you wish.)

One of these is a food waybill, understandable as a preferred movement, but the other is chosen to represent urgently needed parts for production. The one on the right has a pencil notation on it, as I add to many bills, as a partial representation of the very common handwriting additions and corrections to prototype waybills.

These preferred-movement bills will add some variety to my waybill operation, and will serve, as does the occasional LCL waybill marked “stop this car at . . .”, to keep crews on their toes.

Tony Thompson

Saturday, December 12, 2015

A plant switcher at Jupiter Pump & Compressor

I have written in earlier posts about my plans for a Jupiter Pump and Compressor Company plant at the town of Ballard on my layout, intended to represent one of the larger industries on the layout (see for example: http://modelingthesp.blogspot.com/2015/10/jupiter-pump-compressor-part-2.html ). I had always had the idea that I could suggest a much larger plant than there was space to actually model, by having a plant switcher and some non-interchange cars on the plant siding(s).

This idea had languished for some time, meandering along the lines of possibly a small steam engine, likely a tank type to keep the size minimal. Somewhere in all my stuff is an ancient Varney “Dockside” 0-4-0, suitably small but unfortunately all too recognizable as one of the hobby’s classics. There is also an 0-6-0 tank engine among my older models in storage. But no decisions had been made. This topic began to rise to the surface, however, with the completion of track to the plant, as shown in the post cited at the top of the present post.

I was still at the no-decision stage, when I happened to visit the Athearn booth at the National Train Show in Portland last August (as usual, in conjunction with the national convention of NMRA). There I saw their new EMD Model 40 locomotive, a very small industrial switcher. The light over my head definitely went on. Even though the model would not come equipped with DCC, it could still be used as a display piece, which is how I was leaning anyway. But at that time, the model was not yet available.

I did some quick checking to see if this locomotive might make sense on my layout. EMD built just eleven of these 300-horsepower units, between 1940 and 1943. Beyond the two engines which EMD kept as plant switchers, five of them went to the U.S. Army and Navy for switching on military bases, and four others went to the government’s Defense Plant Corporation. At least some became surplus after the war and ended up in a variety of places. I decided that Jupiter, being a west coast company, certainly could have acquired one from the military or DPC. All this started me itching to buy one, but Athearn continued to say that the model was “coming.”

Still, I could now think about how to manage the placement and even the use of this switcher. I had already organized a pair of sidings into the Jupiter plant. Maybe I could add a third, dummy siding as well, to display the switcher and probably an in-plant car or two. I have gradually accumulated several freight cars which would fit this category. As this “planning” slowly progressed, I heard from a source that you could now buy the Model 40 direct from Athearn, so I went ahead and did so. It arrived quickly and looked as great as I remembered from Portland.

As soon as I could get the locomotive lettered, I took this photo. The lettering is from an old Walthers alphabet set, “Square Gothic Extended #8,” which I had buried in my decal stash.

The locomotive received a little weathering, especially on the running gear, and was ready for placement on the layout, at least to try it out in the selected location for the dummy siding. I decided to try it next to an in-plant type of car I created some years back, a European side-door gondola fitted with conventional U.S. trucks.Here you see them on a piece of flextrack just set in place. Foreground track is also just resting in place.

I think this will work out well, using the Model 40 essentially as scenery in front of the plant. And if need be, I might always be able to go back and squeeze a DCC decoder into it for operation.

Tony Thompson

This idea had languished for some time, meandering along the lines of possibly a small steam engine, likely a tank type to keep the size minimal. Somewhere in all my stuff is an ancient Varney “Dockside” 0-4-0, suitably small but unfortunately all too recognizable as one of the hobby’s classics. There is also an 0-6-0 tank engine among my older models in storage. But no decisions had been made. This topic began to rise to the surface, however, with the completion of track to the plant, as shown in the post cited at the top of the present post.

I was still at the no-decision stage, when I happened to visit the Athearn booth at the National Train Show in Portland last August (as usual, in conjunction with the national convention of NMRA). There I saw their new EMD Model 40 locomotive, a very small industrial switcher. The light over my head definitely went on. Even though the model would not come equipped with DCC, it could still be used as a display piece, which is how I was leaning anyway. But at that time, the model was not yet available.

I did some quick checking to see if this locomotive might make sense on my layout. EMD built just eleven of these 300-horsepower units, between 1940 and 1943. Beyond the two engines which EMD kept as plant switchers, five of them went to the U.S. Army and Navy for switching on military bases, and four others went to the government’s Defense Plant Corporation. At least some became surplus after the war and ended up in a variety of places. I decided that Jupiter, being a west coast company, certainly could have acquired one from the military or DPC. All this started me itching to buy one, but Athearn continued to say that the model was “coming.”

Still, I could now think about how to manage the placement and even the use of this switcher. I had already organized a pair of sidings into the Jupiter plant. Maybe I could add a third, dummy siding as well, to display the switcher and probably an in-plant car or two. I have gradually accumulated several freight cars which would fit this category. As this “planning” slowly progressed, I heard from a source that you could now buy the Model 40 direct from Athearn, so I went ahead and did so. It arrived quickly and looked as great as I remembered from Portland.

As soon as I could get the locomotive lettered, I took this photo. The lettering is from an old Walthers alphabet set, “Square Gothic Extended #8,” which I had buried in my decal stash.

The locomotive received a little weathering, especially on the running gear, and was ready for placement on the layout, at least to try it out in the selected location for the dummy siding. I decided to try it next to an in-plant type of car I created some years back, a European side-door gondola fitted with conventional U.S. trucks.Here you see them on a piece of flextrack just set in place. Foreground track is also just resting in place.

I think this will work out well, using the Model 40 essentially as scenery in front of the plant. And if need be, I might always be able to go back and squeeze a DCC decoder into it for operation.

Tony Thompson

Tuesday, December 8, 2015

Fifth anniversary of this blog

I began this blog about Southern Pacific modeling on December 8,

2010, a date chosen not for any reason other than I was ready to begin that day. And today, here it is, December 8. Once again this year, as has been the case on each of the four anniversaries before this one, I am surprised and impressed with the viewership

this blog has enjoyed, not just this year, but looking back for all five years.

My original intention was to post a couple of times a week, and that has proven to be a good rhythm for me. I have continued over these years in presenting about ten posts per month, and about 120 to 125 per year. The post you are reading is the 620th, so the average rate is exactly 124 per year. These posts have varied widely in how many comments they receive, but as has been increasingly true in recent years, readers with questions, corrections or comments tend to email me directly. That’s not a complaint, just a description.

Page views have continued at a high level. The first year there were about 50,000, a number which seemed impossibly huge to me when I saw it, and far beyond anything I had ever imagined would happen with this blog. The following year there were almost 100,000 more, bring the total to 150,000 after two years. Even more amazing to me.

The third anniversary in 2013 brought to light even bigger annual viewing numbers, reaching almost to 300,000 views total, thus almost 150,000 additional views in that one year alone. Since then, the viewing has continue to increase, though the rate of increase has flattened out quite a bit. The total reached 468,000 views after four years, meaning that there were almost 170,000 new views that year. The number of new views in the fifth year is about the same, another indication of flattening, though of course it remains at an amazingly high level. Total page views since the beginning in December 2010 reached 600,000 just before 5 PM on September 28, 2015, and now has reached a total above 632,000 views. I can’t say it enough times: I am just amazed—and also very gratified.

My original goal was to present a perspective on modeling the SP in HO scale, and to add historical as well as modeling and operating information where possible. Those goals have remained in place, and I feel like I have addressed them in the way I wanted to do. Although not originally central to my plans, it has turned out that modeling projects on my SP layout have formed a significant part of the blog output. That makes it fun, as I now tend to plan any project, whether rolling stock or layout, with photography in mind, to document in a possible future post. This has probably increased my percentage of completed projects, if nothing else!

I will just include one photo from the layout as it now is, showing Ten-wheeler 2344 switching at Shumala. Set into the fascia at right is a push-pull handle for a switch at the back of this scene.

In recent years, the blog has acquired new features too. These include increases in the number of documents posted on Google Docs and available to anyone on the Internet, such as the recent posting of a commodity table for tank cars ( http://modelingthesp.blogspot.com/2015/11/a-tank-car-commodity-table.html ). In addition, there are now reference pages, accessible by the list at the upper right of the top of the blog page. These reference pages were created by combining eleven posts about my method of freight car weathering using acrylic washes, into two reference pages, one on the basic method, the other on specifics for individual car types and additional details.

Although I didn’t begin this blog with very specific plans, least of all with any time frame in mind, I am sure I had no idea that it would extend to five full years and beyond, with over 600 individual posts, nor had I ever remotely imagined more than 600,000 page views in that time. These numbers still make me shake my head. But recognizing that there is a readership increases my motivation to continue, and to enjoy continuing. Thanks for your interest and support.

Tony Thompson

My original intention was to post a couple of times a week, and that has proven to be a good rhythm for me. I have continued over these years in presenting about ten posts per month, and about 120 to 125 per year. The post you are reading is the 620th, so the average rate is exactly 124 per year. These posts have varied widely in how many comments they receive, but as has been increasingly true in recent years, readers with questions, corrections or comments tend to email me directly. That’s not a complaint, just a description.

Page views have continued at a high level. The first year there were about 50,000, a number which seemed impossibly huge to me when I saw it, and far beyond anything I had ever imagined would happen with this blog. The following year there were almost 100,000 more, bring the total to 150,000 after two years. Even more amazing to me.

The third anniversary in 2013 brought to light even bigger annual viewing numbers, reaching almost to 300,000 views total, thus almost 150,000 additional views in that one year alone. Since then, the viewing has continue to increase, though the rate of increase has flattened out quite a bit. The total reached 468,000 views after four years, meaning that there were almost 170,000 new views that year. The number of new views in the fifth year is about the same, another indication of flattening, though of course it remains at an amazingly high level. Total page views since the beginning in December 2010 reached 600,000 just before 5 PM on September 28, 2015, and now has reached a total above 632,000 views. I can’t say it enough times: I am just amazed—and also very gratified.

My original goal was to present a perspective on modeling the SP in HO scale, and to add historical as well as modeling and operating information where possible. Those goals have remained in place, and I feel like I have addressed them in the way I wanted to do. Although not originally central to my plans, it has turned out that modeling projects on my SP layout have formed a significant part of the blog output. That makes it fun, as I now tend to plan any project, whether rolling stock or layout, with photography in mind, to document in a possible future post. This has probably increased my percentage of completed projects, if nothing else!

I will just include one photo from the layout as it now is, showing Ten-wheeler 2344 switching at Shumala. Set into the fascia at right is a push-pull handle for a switch at the back of this scene.

In recent years, the blog has acquired new features too. These include increases in the number of documents posted on Google Docs and available to anyone on the Internet, such as the recent posting of a commodity table for tank cars ( http://modelingthesp.blogspot.com/2015/11/a-tank-car-commodity-table.html ). In addition, there are now reference pages, accessible by the list at the upper right of the top of the blog page. These reference pages were created by combining eleven posts about my method of freight car weathering using acrylic washes, into two reference pages, one on the basic method, the other on specifics for individual car types and additional details.

Although I didn’t begin this blog with very specific plans, least of all with any time frame in mind, I am sure I had no idea that it would extend to five full years and beyond, with over 600 individual posts, nor had I ever remotely imagined more than 600,000 page views in that time. These numbers still make me shake my head. But recognizing that there is a readership increases my motivation to continue, and to enjoy continuing. Thanks for your interest and support.

Tony Thompson

Sunday, December 6, 2015

Athearn tank car parts

Why on earth am I posting about this? Over the years during which I have been writing this blog, I have gotten several queries about how to get Athearn parts, and as it happens, there were two such questions in the last month or so. Accordingly, I will briefly repeat my understanding of the situation.

Athearn does have a parts section to their website (you can visit it at: http://www.athearn.com/ and click on PARTS in the tabs along the top), but in their wisdom they show there only the very best selling parts of their entire line. As an Athearn representative said to me on the phone a few years ago, however, they do stock a great many of the parts which are not shown on the website, and are happy to sell them. You just have to know how to do so. The key is to know the part number, and then to contact Athearn for availability. The contact is their Parts Department, and you can email them at: parts@athearn.com . They will let you know the current price and whether the part is in stock. There is a significant shipping charge regardless of how small your order is.

I suppose the reason I am asked about this issue is because I have written a number of blog posts, and some magazine articles too, which use Athearn tank cars as a starting point or components for models. These tank car parts are usually in stock (if they are out of stock, be patient, as they tend to re-run them reasonably often — or at least they have in the past). It speeds up ordering to know part numbers, and in the case of the old 42-foot tank cars, these have not changed. They are shown on old kit directions, if you have kept copies. If not, I am going to attach them below. Note that the part numbers are helpfully listed in the lower left corner. You can click to enlarge the image.

That is the “regular” tank car, sold as single-dome and triple-dome versions. I have used the triple-dome body (part 14990) for years as a sacrifice body, to cut off dome tops and raise the dome height to the correct size for single-dome cars. The other set of parts (for a car which in Athearn’s version is different only above the bottom sheet) is the so-called “chemical” car:

Here too, the parts are listed at lower left as well as called out for each part in the drawing which serves as kit assembly instructions.

In addition to the sacrifice triple-dome body, one can buy the principal underframe parts if intending to use it for a General American underframe (parts 15503 and 15504), as I have done on occasion. One example was a tank swap, using a cut-down Athearn underframe with an InterMountain tank (you can see it in this post: http://modelingthesp.blogspot.com/2011/01/tank-car-projects-for-cocoa-beach-2.html ). That same project was described in more detail in my article in Railroad Model Craftsman (the issue for July 2011).

On another occasion, I was trying to cut up a “chemical” tank car body, and got the thing angled in my miter box, thus cutting it rather unsquare. I just bought another part no. 15490 and did the job more carefully the second time.

I should say in closing that the old Athearn tank cars (all three described above) are really fairly crude by modern standards, with many details quite inferior to today’s models, and I am fully aware of those shortcomings. But as yet no one else makes a halfway decent General American underframe, which the Athearn parts can be converted into, and as yet we have no good insulated tank body suitable for kitbashing. I can hardly wait for the announced (and badly needed) 6000-gallon insulated tank cars from Broadway Limited, but for now, Athearn remains one modeling route we can use.

Tony Thompson

Athearn does have a parts section to their website (you can visit it at: http://www.athearn.com/ and click on PARTS in the tabs along the top), but in their wisdom they show there only the very best selling parts of their entire line. As an Athearn representative said to me on the phone a few years ago, however, they do stock a great many of the parts which are not shown on the website, and are happy to sell them. You just have to know how to do so. The key is to know the part number, and then to contact Athearn for availability. The contact is their Parts Department, and you can email them at: parts@athearn.com . They will let you know the current price and whether the part is in stock. There is a significant shipping charge regardless of how small your order is.

I suppose the reason I am asked about this issue is because I have written a number of blog posts, and some magazine articles too, which use Athearn tank cars as a starting point or components for models. These tank car parts are usually in stock (if they are out of stock, be patient, as they tend to re-run them reasonably often — or at least they have in the past). It speeds up ordering to know part numbers, and in the case of the old 42-foot tank cars, these have not changed. They are shown on old kit directions, if you have kept copies. If not, I am going to attach them below. Note that the part numbers are helpfully listed in the lower left corner. You can click to enlarge the image.

That is the “regular” tank car, sold as single-dome and triple-dome versions. I have used the triple-dome body (part 14990) for years as a sacrifice body, to cut off dome tops and raise the dome height to the correct size for single-dome cars. The other set of parts (for a car which in Athearn’s version is different only above the bottom sheet) is the so-called “chemical” car:

Here too, the parts are listed at lower left as well as called out for each part in the drawing which serves as kit assembly instructions.

In addition to the sacrifice triple-dome body, one can buy the principal underframe parts if intending to use it for a General American underframe (parts 15503 and 15504), as I have done on occasion. One example was a tank swap, using a cut-down Athearn underframe with an InterMountain tank (you can see it in this post: http://modelingthesp.blogspot.com/2011/01/tank-car-projects-for-cocoa-beach-2.html ). That same project was described in more detail in my article in Railroad Model Craftsman (the issue for July 2011).

On another occasion, I was trying to cut up a “chemical” tank car body, and got the thing angled in my miter box, thus cutting it rather unsquare. I just bought another part no. 15490 and did the job more carefully the second time.

I should say in closing that the old Athearn tank cars (all three described above) are really fairly crude by modern standards, with many details quite inferior to today’s models, and I am fully aware of those shortcomings. But as yet no one else makes a halfway decent General American underframe, which the Athearn parts can be converted into, and as yet we have no good insulated tank body suitable for kitbashing. I can hardly wait for the announced (and badly needed) 6000-gallon insulated tank cars from Broadway Limited, but for now, Athearn remains one modeling route we can use.

Tony Thompson

Thursday, December 3, 2015

Delivering loads from automobile cars

Automobile cars were at one time a car category within the Association of American Railroads (AAR) classifications, namely any box car with double doors. They were still sub-types of the “X” classes, such as XAR for cars with auto racks, or XAP for cars restricted to auto parts, but were recommended to be lettered “AUTOMOBILE” on the car side. This applied to 40-foot, 50-foot, or other length cars, so long as they had double doors.

These cars were not, of course, restricted to service related to automobiles. Many railroads, including Southern Pacific, often would order as many or more cars without special equipment as those with equipment such as auto racks. The rack-less cars could of course be assigned to auto parts service, but at least on SP, were in considerable demand for lumber service. Rough lumber was ordinarily shipped on flat cars or in gondolas, but finished lumber usually moved in box cars, especially double-door cars which were easier to load. Empty Car Directives on SP often requested all empty, non-assigned double-door cars to be sent to lumber-loading areas, such as Eugene and Klamath Falls, Oregon. And naturally these cars would be used for any other large cargo.

I mention this versatility because of the thought process I use in assigning car service to the freight cars on my layout. I have a collection of automobile cars, both 40- and 50-foot length, and sometimes run them as an auto service train on the main line. (SP operated a train called the Los Angeles Auto Parts or LAAP on the Coast Division in the period I model, the early 1950s; these were auto parts which came over the Overland Route and then south to auto assembly plants in Southern California.) But I also gave some thought to ways automobile cars could have destinations on my mythical SP branch, the Santa Rosalia Branch.

An obvious one is lumber, as mentioned above. I don’t have any lumber yards on my layout, but team tracks were very commonly used to deliver cargoes like lumber, and I do have numerous waybills in my system for auto and box cars to deliver lumber to team tracks (and also for flat cars and gondolas to do the same). One can also imagine that a small-town auto dealer might receive assembled automobiles at a team or house track which had a suitable platform for driving the cars away. It’s known that an auto car which held, say, four automobiles might unload a couple of them at one town, and move on to another town for the remainder, especially at the beginning of a model year. I have waybills like that too.

But as I stated above, almost any load too big to load into a single-door box car, or too long for a 40-foot car, might travel in a 50-foot automobile car. Here’s an example I found on the internet, an Aeronca airplane, with wings and tail planes removed, being loaded into a PRR auto car. The truck is lettered for the Aeronca Corporation, located in Middletown, Ohio. Though Aeronca ceased airplane production in 1951 (I model 1953), it continued to produce aircraft parts for others, and also continued to repair, refurbish and resell older Aeronca airplanes. This plane being loaded may be one of the latter.

This is a classic example of a load which is bulky but not terribly heavy, and the auto car will easily carry both the fuselage and wings, along with other parts. It might go to an airport where there is a railroad spur, but could also be delivered to a team track.

I have a brass model of the same type of Pennsylvania auto car (mine is Class X32A), as you see here. The model is a Railworks product. It happens not to have the “AUTOMOBILE” lettering.

I have made up a waybill for a load like the airplane example you see above, for delivery via a team track. This is for a used airplane, probably refurbished, being sold from the Aeronca plant in Middletown. Middletown is served by the New York Central.

Once again, I have taken advantage of the “universal industry” characteristic of team and house tracks, as I have discussed in previous posts. Here is one if them: http://modelingthesp.blogspot.com/2015/10/operations-non-rail-served-customers.html . So you can take advantage of the fact that your team tracks can handle a wide variety of inbound (and outbound) loads, even airplanes!

Tony Thompson

These cars were not, of course, restricted to service related to automobiles. Many railroads, including Southern Pacific, often would order as many or more cars without special equipment as those with equipment such as auto racks. The rack-less cars could of course be assigned to auto parts service, but at least on SP, were in considerable demand for lumber service. Rough lumber was ordinarily shipped on flat cars or in gondolas, but finished lumber usually moved in box cars, especially double-door cars which were easier to load. Empty Car Directives on SP often requested all empty, non-assigned double-door cars to be sent to lumber-loading areas, such as Eugene and Klamath Falls, Oregon. And naturally these cars would be used for any other large cargo.

I mention this versatility because of the thought process I use in assigning car service to the freight cars on my layout. I have a collection of automobile cars, both 40- and 50-foot length, and sometimes run them as an auto service train on the main line. (SP operated a train called the Los Angeles Auto Parts or LAAP on the Coast Division in the period I model, the early 1950s; these were auto parts which came over the Overland Route and then south to auto assembly plants in Southern California.) But I also gave some thought to ways automobile cars could have destinations on my mythical SP branch, the Santa Rosalia Branch.

An obvious one is lumber, as mentioned above. I don’t have any lumber yards on my layout, but team tracks were very commonly used to deliver cargoes like lumber, and I do have numerous waybills in my system for auto and box cars to deliver lumber to team tracks (and also for flat cars and gondolas to do the same). One can also imagine that a small-town auto dealer might receive assembled automobiles at a team or house track which had a suitable platform for driving the cars away. It’s known that an auto car which held, say, four automobiles might unload a couple of them at one town, and move on to another town for the remainder, especially at the beginning of a model year. I have waybills like that too.

But as I stated above, almost any load too big to load into a single-door box car, or too long for a 40-foot car, might travel in a 50-foot automobile car. Here’s an example I found on the internet, an Aeronca airplane, with wings and tail planes removed, being loaded into a PRR auto car. The truck is lettered for the Aeronca Corporation, located in Middletown, Ohio. Though Aeronca ceased airplane production in 1951 (I model 1953), it continued to produce aircraft parts for others, and also continued to repair, refurbish and resell older Aeronca airplanes. This plane being loaded may be one of the latter.

This is a classic example of a load which is bulky but not terribly heavy, and the auto car will easily carry both the fuselage and wings, along with other parts. It might go to an airport where there is a railroad spur, but could also be delivered to a team track.

I have a brass model of the same type of Pennsylvania auto car (mine is Class X32A), as you see here. The model is a Railworks product. It happens not to have the “AUTOMOBILE” lettering.

I have made up a waybill for a load like the airplane example you see above, for delivery via a team track. This is for a used airplane, probably refurbished, being sold from the Aeronca plant in Middletown. Middletown is served by the New York Central.

Once again, I have taken advantage of the “universal industry” characteristic of team and house tracks, as I have discussed in previous posts. Here is one if them: http://modelingthesp.blogspot.com/2015/10/operations-non-rail-served-customers.html . So you can take advantage of the fact that your team tracks can handle a wide variety of inbound (and outbound) loads, even airplanes!

Tony Thompson

Subscribe to:

Comments (Atom)