Nearly all operating sessions I have hosted on my layout, here in Berkeley or when I lived in Pittsburgh, PA, were what you could call “private” sessions, where friends made up the crew. Some came when invited, several came as part of regular “work” nights in Pittsburgh. What I have rarely done was host a session where I did not choose the participants, that is, where people signed up for a chance at sessions, and were assigned to my layout by a third party. That happens as part of some conventions, as was the case here, with the just-concluded 2015 meeting of the Pacific Coast Region of NMRA.

All registrants for the convention were entitled to request operating sessions on any of the available layout they wished, and were asked to rank-order their requests, so that if a high choice was not available, another choice could be awarded. Some layouts are famous and everyone tends to request them, so a ranked list of preferences is an approach to try and apportion resources fairly.

My layout was listed as accommodating four operators per session, as two two-person crews, which is about all that can be kept busy on a layout the size of mine. The sessions were for three hours, 7 to 10 PM on both nights that we operated.

The scheme I designed for these sessions was to start one crew at Shumala with the newly-arrived cars off the SP Guadalupe local, and to carry out all local switching needed. The second crew began at Santa Rosalia, and switched there and at Ballard. As soon as the Ballard train was ready to return to Shumala with the cars it had picked up, I ran the Surf turn, passing by on its way back to San Luis Obispo, which picked up the outbound cars the Shumala crew had set out, and the turn also dropped off another batch of cars for the branch.

I will just show a few snapshots from the two sessions. Below you see Tom Crawford (left) and Stan Keiser working at Shumala at the beginning of the session on the first night. You’ll notice we were all wearing our convention badges on red lanyards.

Meanwhile (below), once they finished at Santa Rosalia, Dave Connery (foreground) and Ed Merrin (partly hidden) switched at Ballard. I’m observing in the background. My job was to hang around and answer questions or try and solve problems, but to stay out of the way.

Then when all Ballard work was complete, the branch train returned to Shumala. Both nights, the crews elected to switch sides of the layout at this point, so that each crew got to switch all the towns. The former Shumala crew thus took all the Ballard-bound cars in their yard, and set off to Ballard, while the former Ballard crew did the additional switching at Shumala with the cars they had brought off the branch, and dealt with the new arrivals off the SP. Both nights, these two assignments combined to take about the full three hours to complete.

Here, in a scene from the second night, is the crew which started at Santa Rosalia, and is now working at Shumala, Jeff Allen at left and Steve Williams.

The operating scheme largely worked well, the crews pretty much understood the work directions and waybills, and rolling stock mostly behaved itself. Each crew probably moved on the order of 50 cars in each session. On the debit side, I still have a few electrical gremlins to slay. But because it was a completely different operating scenario from any previous operating session, it was an interesting challenge, and all in all, I was pleased with how well it went.

Tony Thompson

Monday, May 18, 2015

Friday, May 15, 2015

SP depot, Santa Rosalia, Part 4

In the previous post, Part 3, I described completing the main structure (except the roof), as well as adding an interior second floor (you can read that post at: http://modelingthesp.blogspot.com/2015/04/sp-depot-santa-rosalia-part-3.html ). I also mentioned that I planned to diverge from the kit instructions regarding the roof. In this post, I complete the interior, and address the roof assembly.

I decided to add lengthwise interior walls to reflect the actual floor plan of the second floor of the depot, as shown in the previous post. These also serve as a view block for sightlines through the building. These were just made from styrene, and I chose to leave an open door between the living room (behind the bay section) and the kitchen behind it. I painted them a yellowish brown color.

Next I turned to the roof. Because I wanted to make sure the peel-and-stick shingles would lie as flat as possible, I decided to shingle the roof before adding the rafter tails on the underside of the roof sheets. That way, I could press each roof section under weight to ensure the best possible adherence of the shingles.

The first step is to mark pencil lines on the upper surface of each roof sheet, using the template in the kit instructions as a guide. Though tedious (the kind of procedure I don’t do all in one sitting), this is straightforward. My next step was to airbrush all the sheets of shingle strips the SP depot roof color, Moss Green (Tru-Color no. 154). Be sure you paint the shingle side, not the backing side, as was also important in the sheets of Light Brown depot trim strips. (I confess I had to go back and repaint a few, after failing to make sure that the correct side of every sheet was painted the first time.)

Shown below are three of the roof sheets with pencil lines for shingle alignment, and one sheet of the airbrushed strips of shingle material. (You can click on the image to enlarge it.)

Next I started applying the shingles. Like the task of penciling in the alignment lines, this is a pretty tedious process, though with care it goes smoothly. I did not do over a quarter of any of the roof surfaces at any one sitting, thus preserving my desired happy demeanor. And after each session, I did press the roof pieces having new shingles under weight, and found that this did keep the roof segments flat. The photo below shows some completed and partly completed roof segments (some edges are not trimmed yet).

Note the roof piece with square holes for the chimneys (you can see this same piece in the first photo in this post, with locations penciled in). These locations are measured from the kit directions, and match the flue locations shown in the floor plan of the second floor (previous post, cited at the top of this post).

Once the roof pieces were complete, I added the rafter segments underneath. This went rapidly and easily. I then set about fitting the first floor roof around the building. I immediately discovered an interference. Trim piece D-3, on the second floor wall above the freight room, though located as needed to accommodate the attic windows above, prevented a close fit of the roof pieces to that wall of the building. I carefully cut across the vertical boards on this trim piece and gently pried it free of the wall. I figured I can fit it to the final roof location once the roof is installed.

But once that trim piece was removed, attachment of all four pieces of the first-floor roof went well. The kit directions warn of complications here, though I didn’t really encounter any (except for that misfitting trim piece). Next I turned to the second-floor roof, which I was making removable. As I have done elsewhere, I simply cut styrene “formers” to the roof pitch angle (readily available on the gable walls of the second story) and attached them with canopy glue, along with 1/8-inch square styrene blocking, one strip on each side of each former. For the moment, I ignored the roof over the bay section.

But as soon as the roof structure you see was done, I glued on the bay roof and added a small styrene former inside it, just like the ones in the main roof, above. Note that I omitted rafter ends on what is the back of my model.

Below is the completed model. The freight dock is very nice, though not a great shape for my space, and I may build a new one. Looking at photos of SP depots, particularly CS 22 depots, in Henry Bender’s book (Southern Pacific Lines Standard-Design Depots, Signature Press, 2013), you quickly discover that there were hardly any two freight docks alike, so I feel free to create whatever fits my space best.

Note that the trim piece D-3 above the freight room roof has been re-fitted.

This depot is a great SP structure, and we all owe tremendous thanks to American Model Builders for creating it. Most of it goes together easily and accurately, and though I wouldn’t recommend it to a beginner, I enjoyed the build and found it went quite well. It will be the centerpiece of my town of Santa Rosalia.

Tony Thompson

I decided to add lengthwise interior walls to reflect the actual floor plan of the second floor of the depot, as shown in the previous post. These also serve as a view block for sightlines through the building. These were just made from styrene, and I chose to leave an open door between the living room (behind the bay section) and the kitchen behind it. I painted them a yellowish brown color.

Next I turned to the roof. Because I wanted to make sure the peel-and-stick shingles would lie as flat as possible, I decided to shingle the roof before adding the rafter tails on the underside of the roof sheets. That way, I could press each roof section under weight to ensure the best possible adherence of the shingles.

The first step is to mark pencil lines on the upper surface of each roof sheet, using the template in the kit instructions as a guide. Though tedious (the kind of procedure I don’t do all in one sitting), this is straightforward. My next step was to airbrush all the sheets of shingle strips the SP depot roof color, Moss Green (Tru-Color no. 154). Be sure you paint the shingle side, not the backing side, as was also important in the sheets of Light Brown depot trim strips. (I confess I had to go back and repaint a few, after failing to make sure that the correct side of every sheet was painted the first time.)

Shown below are three of the roof sheets with pencil lines for shingle alignment, and one sheet of the airbrushed strips of shingle material. (You can click on the image to enlarge it.)

Next I started applying the shingles. Like the task of penciling in the alignment lines, this is a pretty tedious process, though with care it goes smoothly. I did not do over a quarter of any of the roof surfaces at any one sitting, thus preserving my desired happy demeanor. And after each session, I did press the roof pieces having new shingles under weight, and found that this did keep the roof segments flat. The photo below shows some completed and partly completed roof segments (some edges are not trimmed yet).

Note the roof piece with square holes for the chimneys (you can see this same piece in the first photo in this post, with locations penciled in). These locations are measured from the kit directions, and match the flue locations shown in the floor plan of the second floor (previous post, cited at the top of this post).

Once the roof pieces were complete, I added the rafter segments underneath. This went rapidly and easily. I then set about fitting the first floor roof around the building. I immediately discovered an interference. Trim piece D-3, on the second floor wall above the freight room, though located as needed to accommodate the attic windows above, prevented a close fit of the roof pieces to that wall of the building. I carefully cut across the vertical boards on this trim piece and gently pried it free of the wall. I figured I can fit it to the final roof location once the roof is installed.

But once that trim piece was removed, attachment of all four pieces of the first-floor roof went well. The kit directions warn of complications here, though I didn’t really encounter any (except for that misfitting trim piece). Next I turned to the second-floor roof, which I was making removable. As I have done elsewhere, I simply cut styrene “formers” to the roof pitch angle (readily available on the gable walls of the second story) and attached them with canopy glue, along with 1/8-inch square styrene blocking, one strip on each side of each former. For the moment, I ignored the roof over the bay section.

But as soon as the roof structure you see was done, I glued on the bay roof and added a small styrene former inside it, just like the ones in the main roof, above. Note that I omitted rafter ends on what is the back of my model.

Below is the completed model. The freight dock is very nice, though not a great shape for my space, and I may build a new one. Looking at photos of SP depots, particularly CS 22 depots, in Henry Bender’s book (Southern Pacific Lines Standard-Design Depots, Signature Press, 2013), you quickly discover that there were hardly any two freight docks alike, so I feel free to create whatever fits my space best.

Note that the trim piece D-3 above the freight room roof has been re-fitted.

This depot is a great SP structure, and we all owe tremendous thanks to American Model Builders for creating it. Most of it goes together easily and accurately, and though I wouldn’t recommend it to a beginner, I enjoyed the build and found it went quite well. It will be the centerpiece of my town of Santa Rosalia.

Tony Thompson

Tuesday, May 12, 2015

Kitbashing the Santa Rosalia cannery

In my previous post (see: http://modelingthesp.blogspot.com/2015/05/flash-tracklayers-enter-santa-rosalia.html ), I showed new trackage entering Santa Rosalia, and in the background are a couple of new structures. This post is about them.

One feature I always wanted to include in my town of Santa Rosalia, which lies just at the Pacific Ocean shore, was a fish cannery. At one time, there were canneries of various sizes at a number of locations on the California coast, and I would have space for a small one. A background flat or nearly flat structure seemed to be the best approach in my limited space, and for a number of years I had kept my eyes open for any kit or other structure, which looked like a cannery to me.

I have considered a substantial number of candidates over those years, without feeling I was getting it right, until one day I happened to look closely at a Walthers “Cornerstone” background building, Arrowhead Ale (Walthers no. 933-3193). Now “ale” sounds great, and tempting as it was to have a brewery on the layout (I do enjoy a good beer from time to time), this structure looked just right to me as a cannery, so I bought one. It’s a two-story building, not too large for my small coastal town, and has a suitably old-fashioned look.

When I opened the box, I discovered that extra parts are included, most prominently a whole bunch of extra windows, and also some extra wall sections. These of course immediately suggested that perhaps I could concoct additions to the structure to make it longer. If built as intended, the main building is 11.5 inches long (the loading platform projects another 3/4 inch), but I could see how to use the 4.25-inch width of that extra wall molding to add to the main building.

Here is the kit box photo, indicating what Walthers had in mind. Of course they have added other buildings alongside, and the appearance of still more buildings behind this one through use of a backdrop. I too have a backdrop, but not an urban one like this.

My first step was to cut up the extra wall section to make a two-story addition to the main building. I only used two stories out of the six in the molding, the bottom piece and the third from the bottom. This comes out very close to the height of the main building, and avoids the round-topped windows, a window style which is not in the main structure.

Once the cuts on pieces one and three were cleaned up, I used Plastruct “Plastic Weld” to join them, as it softens the plastic enough to enable pressing the parts together and squashing any irregularities, to make a tight joint.

I decided to use a distinctly gray grout color on this brick building, and also to color the window lintels and sills as concrete. I completed those steps before the windows were installed. Then after the windows and doors were installed, I used mixtures of acrylic tube Raw Umber and Yellow Ochre to touch up the stone of the base wall area. With that complete, I did some weathering of the walls with acrylic washes, in my usual way. Here are the wall panels at this point. The panel at left is the assembly of the cut pieces shown in the photo above.

I could now assemble the structure, simply following kit directions. I added a few window shades, and for the leftmost piece in the photo above, a plain gray backing as a view block for the windows. Here you see the structure in place on the layout, with the Pismo Marine Services building at left. (You can click on the image to enlarge it.)

(Pismo Marine was made from one of the buildings in a KingMill Enterprises background flat, their “Commerce Street No. 9,” just one of a series of superb products. That same flat was the source from which I created my Caslon Printing Company, which you can view at this link: http://modelingthesp.blogspot.com/2013/02/background-flats-2-kitbashing.html . You can visit their site to see all their fine backdrop buildings, at: http://www.kingmill.com/All-Products_c_9-2.html .)

You may notice that the business in my cannery is named “Martinelli Brothers.” There was once a prototype Martinelli Brothers fish cannery in northern California, part of the one-time dominance of the California fishing fleet by Italian immigrants. It is no coincidence that all the big restaurants around San Francisco’s Fisherman’s Wharf bear the names of Italian-heritage proprietors.

Both these simple background buildings turned out well, from my viewpoint, and are not only interesting and appropriate industries, but also help set the coastal location for my town of Santa Rosalia.

Tony Thompson

One feature I always wanted to include in my town of Santa Rosalia, which lies just at the Pacific Ocean shore, was a fish cannery. At one time, there were canneries of various sizes at a number of locations on the California coast, and I would have space for a small one. A background flat or nearly flat structure seemed to be the best approach in my limited space, and for a number of years I had kept my eyes open for any kit or other structure, which looked like a cannery to me.

I have considered a substantial number of candidates over those years, without feeling I was getting it right, until one day I happened to look closely at a Walthers “Cornerstone” background building, Arrowhead Ale (Walthers no. 933-3193). Now “ale” sounds great, and tempting as it was to have a brewery on the layout (I do enjoy a good beer from time to time), this structure looked just right to me as a cannery, so I bought one. It’s a two-story building, not too large for my small coastal town, and has a suitably old-fashioned look.

When I opened the box, I discovered that extra parts are included, most prominently a whole bunch of extra windows, and also some extra wall sections. These of course immediately suggested that perhaps I could concoct additions to the structure to make it longer. If built as intended, the main building is 11.5 inches long (the loading platform projects another 3/4 inch), but I could see how to use the 4.25-inch width of that extra wall molding to add to the main building.

Here is the kit box photo, indicating what Walthers had in mind. Of course they have added other buildings alongside, and the appearance of still more buildings behind this one through use of a backdrop. I too have a backdrop, but not an urban one like this.

My first step was to cut up the extra wall section to make a two-story addition to the main building. I only used two stories out of the six in the molding, the bottom piece and the third from the bottom. This comes out very close to the height of the main building, and avoids the round-topped windows, a window style which is not in the main structure.

Once the cuts on pieces one and three were cleaned up, I used Plastruct “Plastic Weld” to join them, as it softens the plastic enough to enable pressing the parts together and squashing any irregularities, to make a tight joint.

I decided to use a distinctly gray grout color on this brick building, and also to color the window lintels and sills as concrete. I completed those steps before the windows were installed. Then after the windows and doors were installed, I used mixtures of acrylic tube Raw Umber and Yellow Ochre to touch up the stone of the base wall area. With that complete, I did some weathering of the walls with acrylic washes, in my usual way. Here are the wall panels at this point. The panel at left is the assembly of the cut pieces shown in the photo above.

I could now assemble the structure, simply following kit directions. I added a few window shades, and for the leftmost piece in the photo above, a plain gray backing as a view block for the windows. Here you see the structure in place on the layout, with the Pismo Marine Services building at left. (You can click on the image to enlarge it.)

(Pismo Marine was made from one of the buildings in a KingMill Enterprises background flat, their “Commerce Street No. 9,” just one of a series of superb products. That same flat was the source from which I created my Caslon Printing Company, which you can view at this link: http://modelingthesp.blogspot.com/2013/02/background-flats-2-kitbashing.html . You can visit their site to see all their fine backdrop buildings, at: http://www.kingmill.com/All-Products_c_9-2.html .)

You may notice that the business in my cannery is named “Martinelli Brothers.” There was once a prototype Martinelli Brothers fish cannery in northern California, part of the one-time dominance of the California fishing fleet by Italian immigrants. It is no coincidence that all the big restaurants around San Francisco’s Fisherman’s Wharf bear the names of Italian-heritage proprietors.

Both these simple background buildings turned out well, from my viewpoint, and are not only interesting and appropriate industries, but also help set the coastal location for my town of Santa Rosalia.

Tony Thompson

Sunday, May 10, 2015

Flash! Tracklayers enter Santa Rosalia!

For a couple of years now, I have been describing my goals for the end of my mythical SP branch line, at the seacoast town of Santa Rosalia. In the fall of 2013, I was building the benchwork and completing the backdrop extension to that corner of the layout (see: http://modelingthesp.blogspot.com/2014/01/constructing-santa-rosalia-backdrop.html ). In the summer of 2014, I was starting on modeling the water’s edge (read about it at: http://modelingthesp.blogspot.com/2014/07/constructing-santa-rosalia-waters-edge.html ). More recently, I have been posting about constructing the American Model Builders kit for the SP Common Standard No. 22 depot (for example, recently at: http://modelingthesp.blogspot.com/2015/03/sp-depot-santa-rosalia-part-2.html ), and about the trestle to carry the track from Ballard over Oso Flaco Creek into Santa Rosalia (check it out: http://modelingthesp.blogspot.com/2015/04/building-sp-pile-trestle.html ). But all these things are preliminaries.

When the Santa Rosalia name was chosen, I wanted to use one of the typical Spanish saint’s names, as are so common in California as well as throughout Latin America, but did not want to choose one already used in California. There is a real Santa Rosalia (a small place) in Baja California but not in American California, so I chose that. For those unsure of my modeled area, I described some time ago the layout locale that I envision for my mythical branch line, including a map with the location of Santa Rosalia. You can view it at: http://modelingthesp.blogspot.com/2011/01/layout-design-locale.html .

With operating sessions on my layout coming up at the rapidly approaching convention of Pacific Coast Region (NMRA), I was determined to get some trackage into Santa Rosalia to extend the switching work to that point. Essentially there is a kind of yard throat as a train enters Santa Rosalia, with multiple switches giving access to multiple tracks (the cannery track, house track, main, and siding). In my column for the “Getting Real” series in Model Railroad Hobbyist, for October 2014 (you can download any issue of MRH free at their site, http://model-railroad-hobbyist.com/magazine ), I presented schematic maps for some of my towns, but not for Santa Rosalia, mostly because the track plan was in flux. But it is now pretty well set. It’s shown below as it’s being built.

Here are some views of the new track at Santa Rosalia. First, I show the curving track that has just crossed the creek, and extends into town. And yes, that’s actually a box of Varney spikes on the right (sold as 1/4-pound of spikes, “over 3000 spikes”). I bought this box back in the 1970s for my first layout efforts, and I still have about a third of a box. The water tank is not in its correct location; it will be placed down past the depot.

Looking farther to the right of the above photo, the current extent of track is shown. Obviously I already have both the “cannery track” buildings in place (see map above). But rather than talk about them now, I will describe their construction in my next post.

At lower right, you see the Xeroxed three-way switch that will be located there.

It’s fun to be able to operate into Santa Rosalia, something I have waiting a long time to do. And it will give my operating session crews more to do also.

Tony Thompson

When the Santa Rosalia name was chosen, I wanted to use one of the typical Spanish saint’s names, as are so common in California as well as throughout Latin America, but did not want to choose one already used in California. There is a real Santa Rosalia (a small place) in Baja California but not in American California, so I chose that. For those unsure of my modeled area, I described some time ago the layout locale that I envision for my mythical branch line, including a map with the location of Santa Rosalia. You can view it at: http://modelingthesp.blogspot.com/2011/01/layout-design-locale.html .

With operating sessions on my layout coming up at the rapidly approaching convention of Pacific Coast Region (NMRA), I was determined to get some trackage into Santa Rosalia to extend the switching work to that point. Essentially there is a kind of yard throat as a train enters Santa Rosalia, with multiple switches giving access to multiple tracks (the cannery track, house track, main, and siding). In my column for the “Getting Real” series in Model Railroad Hobbyist, for October 2014 (you can download any issue of MRH free at their site, http://model-railroad-hobbyist.com/magazine ), I presented schematic maps for some of my towns, but not for Santa Rosalia, mostly because the track plan was in flux. But it is now pretty well set. It’s shown below as it’s being built.

Here are some views of the new track at Santa Rosalia. First, I show the curving track that has just crossed the creek, and extends into town. And yes, that’s actually a box of Varney spikes on the right (sold as 1/4-pound of spikes, “over 3000 spikes”). I bought this box back in the 1970s for my first layout efforts, and I still have about a third of a box. The water tank is not in its correct location; it will be placed down past the depot.

Looking farther to the right of the above photo, the current extent of track is shown. Obviously I already have both the “cannery track” buildings in place (see map above). But rather than talk about them now, I will describe their construction in my next post.

At lower right, you see the Xeroxed three-way switch that will be located there.

It’s fun to be able to operate into Santa Rosalia, something I have waiting a long time to do. And it will give my operating session crews more to do also.

Tony Thompson

Thursday, May 7, 2015

Building a California tankhouse, Part 2

In Part 1 (see it at: http://modelingthesp.blogspot.com/2015/04/building-california-tankhouse.html ), I gave the background of these interesting structures, and showed my construction of the bottom part, the upward-tapering enclosure of the tank supports. The structure is completed in this post.

In the prototype tankhouses I have looked at, the upper part, the “upper story,” has the same or almost the same dimensions as the ground footprint of the lower part. To model this, I used Evergreen styrene “Novelty Siding,” 0.040-inch thickness, no. 4083. I simply cut out sides and ends with the same footprint as my first story. In thinking about windows for this upper story, I realized that there seem to be no two of these prototype structures alike in number or placement of windows, so almost any arrangement would be acceptable. I chose a window from my scrapbox, a left-over from a Campbell kit of long ago.

Next the window frame was painted SP Light Brown (Tru-Color Paint no. 163) and the four sides and floor of the upper story were airbrushed SP Colonial Yellow (TCP no. 153). Now I was ready to assemble this top story. (The center of the floor didn’t need to be painted.)

As you can see, I decided to place the window in one end of the top story.

I used my usual styrene structure assembly method, with 1/8-inch square styrene inside all corners. Here are the parts that you saw above, assembled including trim strips, and ready to mate with the first story.

My next job was the roof. I used Rix “Pikestuff” styrene shingled roofing, their part no. 1007, prepainted SP’s standard roof color, Moss Green (Tru-Color no. 154). A narrow strip of flashing along the peak completed the roof. I then used canopy glue to attach the two stories together.

The tank house is now complete except for weathering. It will be part of my stock pen, as the former water source for watering troughs. (I introduced the subject of this stock pen in a prior post; you can read it at this link: http://modelingthesp.blogspot.com/2015/03/a-stock-pen-for-east-shumala.html .) Like many of these tankhouses, it would have been made obsolete as a tank when domestic water became available in small towns. I will show it again when the stock pen complex is complete, which I expect to be soon.

Tony Thompson

In the prototype tankhouses I have looked at, the upper part, the “upper story,” has the same or almost the same dimensions as the ground footprint of the lower part. To model this, I used Evergreen styrene “Novelty Siding,” 0.040-inch thickness, no. 4083. I simply cut out sides and ends with the same footprint as my first story. In thinking about windows for this upper story, I realized that there seem to be no two of these prototype structures alike in number or placement of windows, so almost any arrangement would be acceptable. I chose a window from my scrapbox, a left-over from a Campbell kit of long ago.

Next the window frame was painted SP Light Brown (Tru-Color Paint no. 163) and the four sides and floor of the upper story were airbrushed SP Colonial Yellow (TCP no. 153). Now I was ready to assemble this top story. (The center of the floor didn’t need to be painted.)

As you can see, I decided to place the window in one end of the top story.

I used my usual styrene structure assembly method, with 1/8-inch square styrene inside all corners. Here are the parts that you saw above, assembled including trim strips, and ready to mate with the first story.

My next job was the roof. I used Rix “Pikestuff” styrene shingled roofing, their part no. 1007, prepainted SP’s standard roof color, Moss Green (Tru-Color no. 154). A narrow strip of flashing along the peak completed the roof. I then used canopy glue to attach the two stories together.

The tank house is now complete except for weathering. It will be part of my stock pen, as the former water source for watering troughs. (I introduced the subject of this stock pen in a prior post; you can read it at this link: http://modelingthesp.blogspot.com/2015/03/a-stock-pen-for-east-shumala.html .) Like many of these tankhouses, it would have been made obsolete as a tank when domestic water became available in small towns. I will show it again when the stock pen complex is complete, which I expect to be soon.

Tony Thompson

Monday, May 4, 2015

Constructing section buildings, Part 2

In my previous post on this topic, I described the construction of the main part of the building, but did not address the complexities of the roofs. (See: http://modelingthesp.blogspot.com/2014/03/constructing-section-buildings-part-1.html ). In this post, I describe completing the roofs.

Before continuing, I want to mention that there are very complete drawings for SP tool houses in Volume 2 of the series, Southern Pacific Lines Common Standard Plans (Steam Age Equipment Company, Dunsmuir, CA, 1993), as well as a few photos. Anyone desiring more detail, particularly in the interior, or other variations, can profitably examine these drawings.

Southern Pacific usually shingled the roofs of these kinds of section facilities, at least until the 1940s. Rolled (tarpaper-type) roofing was also seen in some instances, particularly as roofs were replaced. In the past, I have used Sylvan Products molded shingle roofing. Rix Products “Pikestuff” also makes a very nice styrene sheet of shingled roof material. From time to time, I have applied the individual rows of stick-on shingles, such as those produced by Campbell, but that method can leave far too much variation among shingles, and relief of individual shingles, to be realistic for even a rarely-maintained roof. That type of shingling has to be applied, in my opinion, only when you can weight shingled roof sections for a time to ensure everything sticks down tight.

To install the roofing material, I needed to complete the support structure for the roof. As I have done with other structures, I used the triangular off-cuts from cutting out the building ends, to re-combine into a segment with the identical roof pitch used on the building ends. I showed clear photographs of this process in my November, 2012 column in the on-line magazine Model Railroad Hobbyist or MRH. Like all MRH issues, that issue can be downloaded free at: http://model-railroad-hobbyist.com/magazine/mrh-2012-11-nov . (That column was about scratchbuilding an SP depot for my town of Shumala.)

I used the cross-beam at the open end of the large structure to support the triangular end pieces. Once the triangles were in place, I also added a center beam, which will be painted Colonial Yellow to act as the top of the structure side of the taller part of the building.

You may be wondering why one end of the structure has no wall. That will become clear below.

Next came roof sections. For the AL&W kit, shown in the first post on this topic, I could use the roof segments and shingles provided in the kit. For the scratchbuilt building, I simply cut rectangles from Rix “Pikestuff” no. 1007 styrene shingle roof material, duplicating the end and side overhang of the roof on the AL&W building (the overhangs are about a foot on both sides and ends).

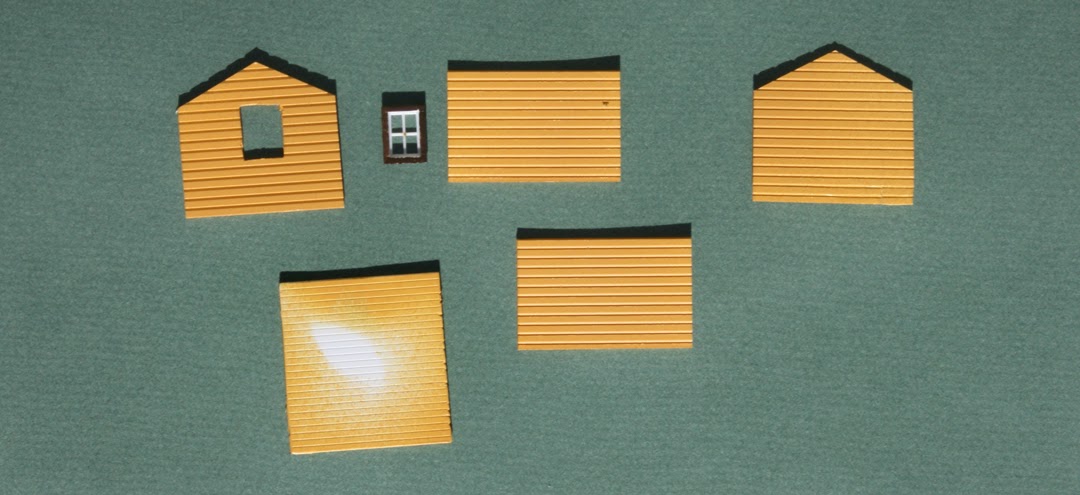

With the Rix roof sections cut to size, I airbrushed them with the Tru-Color paint for the SP color, no. TCP-154, Moss Green. They were then attached with ordinary styrene cement, Meanwhile, the A&LW kit roof was also glued in place. Here are the completed buildings.

The roofs and walls have been lightly weathered in the view above.

Now for the reason that there is no end wall on my larger building. It is intended to cover a switch machine which had to be mounted on the layout surface, on account of inadequate space below it. Here you can see the installed machine. The background track leads to Jupiter Pump & Compressor.

Yes, the twin-coil switch machine is really a Kemtron from some years ago. The building covering this machine should be an easy lift-off for maintenance purposes, and that’s how it was designed.

The building fits just as planned, and here is the same scene shown above, but with the new buildings in place. Ground cover obviously not yet applied.

This was a simple project with a specific goal, hiding the switch machine, and it came out well from my perspective. And the structures were pretty easy to build using styrene.

Tony Thompson

Before continuing, I want to mention that there are very complete drawings for SP tool houses in Volume 2 of the series, Southern Pacific Lines Common Standard Plans (Steam Age Equipment Company, Dunsmuir, CA, 1993), as well as a few photos. Anyone desiring more detail, particularly in the interior, or other variations, can profitably examine these drawings.

Southern Pacific usually shingled the roofs of these kinds of section facilities, at least until the 1940s. Rolled (tarpaper-type) roofing was also seen in some instances, particularly as roofs were replaced. In the past, I have used Sylvan Products molded shingle roofing. Rix Products “Pikestuff” also makes a very nice styrene sheet of shingled roof material. From time to time, I have applied the individual rows of stick-on shingles, such as those produced by Campbell, but that method can leave far too much variation among shingles, and relief of individual shingles, to be realistic for even a rarely-maintained roof. That type of shingling has to be applied, in my opinion, only when you can weight shingled roof sections for a time to ensure everything sticks down tight.

To install the roofing material, I needed to complete the support structure for the roof. As I have done with other structures, I used the triangular off-cuts from cutting out the building ends, to re-combine into a segment with the identical roof pitch used on the building ends. I showed clear photographs of this process in my November, 2012 column in the on-line magazine Model Railroad Hobbyist or MRH. Like all MRH issues, that issue can be downloaded free at: http://model-railroad-hobbyist.com/magazine/mrh-2012-11-nov . (That column was about scratchbuilding an SP depot for my town of Shumala.)

I used the cross-beam at the open end of the large structure to support the triangular end pieces. Once the triangles were in place, I also added a center beam, which will be painted Colonial Yellow to act as the top of the structure side of the taller part of the building.

You may be wondering why one end of the structure has no wall. That will become clear below.

Next came roof sections. For the AL&W kit, shown in the first post on this topic, I could use the roof segments and shingles provided in the kit. For the scratchbuilt building, I simply cut rectangles from Rix “Pikestuff” no. 1007 styrene shingle roof material, duplicating the end and side overhang of the roof on the AL&W building (the overhangs are about a foot on both sides and ends).

With the Rix roof sections cut to size, I airbrushed them with the Tru-Color paint for the SP color, no. TCP-154, Moss Green. They were then attached with ordinary styrene cement, Meanwhile, the A&LW kit roof was also glued in place. Here are the completed buildings.

The roofs and walls have been lightly weathered in the view above.

Now for the reason that there is no end wall on my larger building. It is intended to cover a switch machine which had to be mounted on the layout surface, on account of inadequate space below it. Here you can see the installed machine. The background track leads to Jupiter Pump & Compressor.

Yes, the twin-coil switch machine is really a Kemtron from some years ago. The building covering this machine should be an easy lift-off for maintenance purposes, and that’s how it was designed.

The building fits just as planned, and here is the same scene shown above, but with the new buildings in place. Ground cover obviously not yet applied.

This was a simple project with a specific goal, hiding the switch machine, and it came out well from my perspective. And the structures were pretty easy to build using styrene.

Tony Thompson

Friday, May 1, 2015

Kitbashing an Anchor LPG tank car

Several years ago, Richard Hendrickson and I happened to discuss a tank car project we both were interested in doing. It is an AC&F-built LPG (Liquified Petroleum Gas) tank car owned by the Anchor Petroleum Company of Tulsa, Oklahoma. Five of these cars were built for Anchor in December 1944, numbered ANPX 2410, 2420, 2430, 2440 and 2450. These were 10,500-gallon insulated cars, and Richard and I were both aware that this is about the tank size of the Athearn “chemical” car, suggesting an obvious starting point. Here is a prototype photo, from AC&F, courtesy Ed Kaminski.

This photo is also on page 100 of Kaminski’s book, American Car and Foundry Company, 1899–1999 (Signature Press, 1999), now out of print. And there used to be a Champ decal set, no. HT-60, for this white-lettering paint scheme.

After World War II, however, Anchor began to use a different paint scheme for its ICC-105-type cars like this, with reversed lettering, that is, black on aluminum, with either the entire tank, or just the upper part above the bottom sheet, being aluminum. Either scheme is dramatic, with the size of the “ANCHOR” lettering. Champ once offered a set for the black lettering, set HT-160.

For this scheme, the white lettering would have to come from set HT-60 and the black lettering from set HT-160. For my 1953 modeling date, either scheme is all right, and the aluminum scheme would show off details better.

For modeling, the Athearn car has a General American underframe instead of AC&F, and has the well-known problem that its valve bonnet and platform are hugely out of scale, actually a little too big even for S scale. (See for example my blog post showing the oversize nature of the Athearn bonnet, which is at: http://modelingthesp.blogspot.com/2010/12/upgrading-old-models-2.html .) There are replacement options for the bonnet, though, and as seen above, this Anchor car did not have a platform, only a short walkway on one side. The underframe can certainly be modified in the right direction, so the project looked feasible. I will show photos of the car I am working on, following Richard’s lead.

The first step was to clean up the tank body, removing the Athearn valve bonnet, platform, and handrail supports, and shaving off the incorrect rivets on the bottom sheet. Added here is a resin valve bonnet, given to me years ago by Frank Hodina, and a short walkway below the bonnet (as you see in the prototype photo above) on the right side of the car. Brass wire grab irons were also added at the four corners of the tank. Here is the tank at this point. Holes have been drilled for handrail stanchions.

The underframe received end sills built from styrene channel, then side sills from the bolster to the end sills.

Once the weight is installed inside the tank, and the tank screwed to the underframe, short brass wires were used to represent the tank hold-downs at the bolster (see photo above). The Athearn underframe uses an I-beam-like support for the running board, extending from the center sill, but the AC&F ones were usually diagonal channels. That exact part is in the Tichy tank car detail set, so those supports were added.

Finally, as can be seen in the prototype photo at top, the Anchor cars used the common AC&F arrangement with the brake reservoir near the running board, with the brake valve immediately above it. This is fairly different from the Athearn underframe, so the Athearn reservoir and valve were removed. (And of course the three bottom outlets molded on the Athearn bottom sheet were removed.)

Addition and completion of the brake gear is next, followed by installing handrail posts and forming a new handrail for the car.

I will continue with progress on this model in a future post.

Tony Thompson

This photo is also on page 100 of Kaminski’s book, American Car and Foundry Company, 1899–1999 (Signature Press, 1999), now out of print. And there used to be a Champ decal set, no. HT-60, for this white-lettering paint scheme.

After World War II, however, Anchor began to use a different paint scheme for its ICC-105-type cars like this, with reversed lettering, that is, black on aluminum, with either the entire tank, or just the upper part above the bottom sheet, being aluminum. Either scheme is dramatic, with the size of the “ANCHOR” lettering. Champ once offered a set for the black lettering, set HT-160.

For this scheme, the white lettering would have to come from set HT-60 and the black lettering from set HT-160. For my 1953 modeling date, either scheme is all right, and the aluminum scheme would show off details better.

For modeling, the Athearn car has a General American underframe instead of AC&F, and has the well-known problem that its valve bonnet and platform are hugely out of scale, actually a little too big even for S scale. (See for example my blog post showing the oversize nature of the Athearn bonnet, which is at: http://modelingthesp.blogspot.com/2010/12/upgrading-old-models-2.html .) There are replacement options for the bonnet, though, and as seen above, this Anchor car did not have a platform, only a short walkway on one side. The underframe can certainly be modified in the right direction, so the project looked feasible. I will show photos of the car I am working on, following Richard’s lead.

The first step was to clean up the tank body, removing the Athearn valve bonnet, platform, and handrail supports, and shaving off the incorrect rivets on the bottom sheet. Added here is a resin valve bonnet, given to me years ago by Frank Hodina, and a short walkway below the bonnet (as you see in the prototype photo above) on the right side of the car. Brass wire grab irons were also added at the four corners of the tank. Here is the tank at this point. Holes have been drilled for handrail stanchions.

The underframe received end sills built from styrene channel, then side sills from the bolster to the end sills.

Once the weight is installed inside the tank, and the tank screwed to the underframe, short brass wires were used to represent the tank hold-downs at the bolster (see photo above). The Athearn underframe uses an I-beam-like support for the running board, extending from the center sill, but the AC&F ones were usually diagonal channels. That exact part is in the Tichy tank car detail set, so those supports were added.

Finally, as can be seen in the prototype photo at top, the Anchor cars used the common AC&F arrangement with the brake reservoir near the running board, with the brake valve immediately above it. This is fairly different from the Athearn underframe, so the Athearn reservoir and valve were removed. (And of course the three bottom outlets molded on the Athearn bottom sheet were removed.)

Addition and completion of the brake gear is next, followed by installing handrail posts and forming a new handrail for the car.

I will continue with progress on this model in a future post.

Tony Thompson

Subscribe to:

Posts (Atom)