Business cars, or as they are more often called by railroaders, “official” cars, are a distinctive part of the image of a railroad. Ordinarily they demonstrate that one or more officials are “out on the line,” overseeing their responsibility, most commonly a Division Superintendent traveling his territory. As a Southern Pacific modeler, I wanted to have such a car for my layout.

Many years ago, I picked up one of the Rivarossi observation cars (imported at that time by Associated Hobby Manufacturers, or AHM), complete with interior. It’s a nice model, and has air-conditioning ducts on its roof. At the time I acquired it, I had little knowledge of SP business cars, and contacted a friend with SP knowledge. He told me that the car assigned to the Superintendent of Coast Division, which I model, was named Coast, and was numbered SP 122.

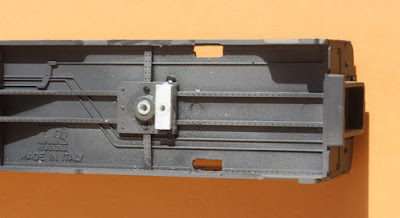

I proceeded to repaint and letter the car as SP 122, but made no

other changes (it’s shown below as originally modeled). My late friend, Paul Koehler, a

long-time SP employee, took one look at the model and said “That’s not

even close to the real Coast!!” I didn’t doubt he was right, but I had no other resources at the time.

At that time, Wilbur Whittaker was still alive, and I contacted him to see if he had a photo of the Coast Division business car. He did, and I purchased a print. I show the photo below. It was taken at San Francisco in November 1947. Some things jumped out at me: the car number is 119, not 122, it isn’t air conditioned, and it has truss rods. (Note that the “SP 119” lettering looks freshly repainted, while the word “Coast” does not. You can click on the image to enlarge it.)

At

this point, I set aside the Rivarossi car, because of all its differences, including that its windows were quite

differently arranged than this prototype photo of the left side of the car.

Then in the latter part of the 1990s, I was working on the book project that became Southern Pacific’s Coast Line Pictorial

(with John Signor), eventually published in 2000. I had a large group

of photos taken at San Luis Obispo by Malcolm “Mac” Gaddis when he

worked there in the early 1950s, and among them was this shot of SP 119,

arriving at San Luis on the rear of the “Coast Mail,” Train 72. In the

background at right is the Hotel Park, and the left background shows the

Juillard-Cockcroft wholesale foods warehouse. Date is August 1953, and

the car is clearly air-conditioned here.

Then along came a new book. As with the passenger car book series from the SP Historical & Technical Society, now SP followers had a superb book about SP official cars, Southern Pacific Official Cars, by Donald M. Munger and Jeffrey Alan Cauthen (SPH&TS, Upland, CA, 2015).

It’s a 528-page hardbound book, 8.5 x 12 inch pages, bound on the short edge. It is still available from the Society, and here’s a link to the purchase point: https://sphts.org/product-category/books/page/2/ . I should mention that in addition to the well-renowned “business” cars, the book also covers instruction, company service, hospital, and private cars, as mentioned on the dust jacket.

I haven’t commented on this book before in the blog, because I purchased it awhile after it was new, but it is worth mentioning how complete it is. And this is not a simple matter. SP changed the name and assignment of many official cars numerous times, and sometimes changed the car number as well. Tracking down the history of a particular car body is truly challenging, but the authors have done so for nearly all known official cars.

What does the SPH&TS book tell us about Coast Division official cars? and did it lead to any modifications to the Rivarossi model? I immediately found that the book does document that SP 122 was indeed named Coast from 1921 to 1932 (so the person who gave me that car number wasn’t entirely wrong). But in 1932 SP 119 became Coast, not at all an unusual kind of changeover in the SP official car fleet. I’ll return to that topic, and to upgrades to the car, in a future post.

Tony Thompson