Two years ago, in early March 2020, I and many others had plane reservations, hotel reservations, and a sign-up for the semi-annual Seattle-Tacoma area event, SoundRail. But of course the pandemic exploded, the event was cancelled, and we entered the long shut-down of most operating sessions. But now it’s 2022, an even-numbered year, normal schedule for SoundRail. This time, the event did take place, and I was delighted to be there.

The three-day event meant operating on three layouts, plus a “pre-event” event on the Thursday beforehand added a fourth layout. I was lucky enough to get signed up for Joe Green’s “Ryder Gap Subdivision” HO scale layout for the pre-event, a C&O layout set in 1974 in the mountains of Virginia. This is a beautiful layout, with superb structures, and everything ran very nicely.

The job I had here was the Mill Gap Turn, and shown below is our train, starting switching at Mill Gap. This was very enjoyable because of the handsome structures, and also the extensive switching required. I admire a layout with industries modeled as big enough to justify the number of freight cars we send there.

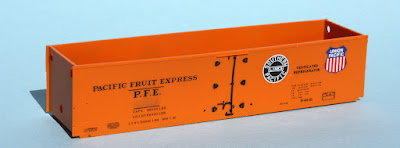

I should also mention the freight cars. I was struck by how much careful attention to weathering is evident in the entire freight car fleet. I will just show one example, clearly reflecting observation of the prototype, a C&O gondola with typical rust pattern inside: partway up the sides. Nicely done!

The following day, I operated at Bill Messecar’s HO scale Santa Fe 3rd Division layout, set in Los Angeles in the transition era. The job I drew was the Corona Turn, and the photo below shows the aisle that contained Corona (at left) and the Porphyry Branch (at right). This was interesting and fun, and I really liked this complete and well-detailed layout.

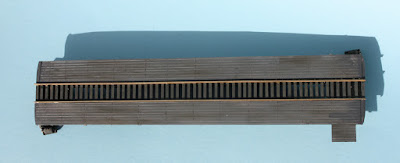

On Saturday, my assignment was Burr Stewart’s Burlington Northern layout, HO scale and set in the Seattle area in 1973. It’s a huge layout, and as Burr himself said, very completely filling the room and then some: “a couple of quarts in a pint pot.” But it ran well, and there was a heck of lot of yard switching (my own favorite), and I was kept busy — but not too busy — the entire day. Definitely a fun operation.

Below you see Stacy Street Yard (Seattle), my assignment, and above it, Burlington Yard, being switched by Dave Houston. He and I shared the aisle space the whole day, but managed to get all our work done anyway. You can see the long grain train just departing my yard, with the blue GN caboose.

On the last day, I had drawn Dale Kreutzer’s Rio Grande Southern, an Sn3 layout set in the 1920s, when the railroad was active and successful. What a pleasure to operate, because it not only ran flawlessly, but had remarkably well-done photo backdrops and very nice structures. My job was the Mancos Turn, and below you see Mancos. As everywhere on the layout, the colors and scale of the backdrops merge seamlessly with the foreground.

One more example of Dale’s excellent blending of backdrop and foreground, the sheep pen at Hesperus. I’m not sure I have ever seen better backdrop incorporation.

This was a great weekend of operation, four outstanding layouts and a great deal of fun and fellowship. I couldn’t have asked for anything more. My heartfelt thanks to the organizers and all the layout owners. Well done.

Tony Thompson