In an earlier post, I described several alternative approaches to waybill design, all stemming from prototype practice, but with different formats and waybill sizes. It was entitled “Waybills-20” and can be found at this link: http://modelingthesp.blogspot.com/2012/03/waybills-20-other-approaches.html . In the present post, I want to update this a bit.

An aspect I had not considered in thinking about waybill design is the problem of the person with weak eyesight. In the latest issue of NMRA Magazine (yes, that’s its full name), for April 2012, there is an interesting article by Jeremy Dummler (pages 34 to 37) about a range of model railroading issue for “a low-vision person.” He mentions the matter of type sizes on model waybills, and of course recommends that both type and document size be larger than might otherwise be desirable. I was flattered that he both followed the general pattern of my waybill designs, and also gave the URL for this blog, as part of his article.

I should also apologize to Jeff Aley, who likewise followed some aspects of my waybill design in devising a waybill system for Tom Weissgerber’s fine layout in Folsom, California. I have mentioned Jeff’s work previously, in comments about the last Cocoa Beach meeting (here’s a link: http://modelingthesp.blogspot.com/2012/01/cocoa-beach-meeting-comments.html ), but that’s not an excuse for failing to describe Jeff’s work more fully, not only because I’ve operated at Tom’s a couple of times and used those waybills, but also because Jeff contributed a segment of the clinic I’m currently giving about waybill design.

Jeff made several interesting changes. First, he wanted to have the car initials and number in the correct prototype location on the final document, so unlike my own bills with car sleeves, he has the blank area at the top. Second, since train crews typically only care about consignee information and ignore the shipper side of the story (which is one reason prototype waybills were typically folded in half the long way, so that only the consignee part was visible), Jeff only showed that part on his bill. Here is what it looks like; you can see the car information (which is on the sleeve, not on the waybill inside the sleeve) in the upper part.

Jeff also simplified his Empty Car Bills, so that all cars moving homeward, that should not be confiscated, have white Empty Car Bills, while yellow Empty Car Bills are used only for cars which can be confiscated. This makes the job of yardmasters on Tom’s layout easier (they also wear the hat of car distributor), because they can easily spot the cars they can confiscate for use, by the yellow color of the paperwork. Even though this is a compromise with the prototype paperwork, in which all Empty Car Bills were the same, it is a compromise which expedites operation. And we all make lots of those.

These two examples expand further the point I wanted to make in my prior post about alternative approaches to a more prototypical waybill: there are various ways this can be done, and more and more modelers are doing so.

Tony Thompson

Thursday, March 29, 2012

Monday, March 26, 2012

Replacing snap-in trucks

Many older models from such sources as AHM, LifeLike, Model Power and others might have car bodies which were attractive starting points for a needed model, but were delivered with snap-in trucks, usually with “Talgo” couplers of the horn-hook variety, looking like this:

These trucks largely had terrible wheelsets, poorly rendered side frames (the one shown above is better than average), and an unacceptable coupler arrangement.

When starting on an upgrade project for one of these cars, I have tried (in the distant past) cutting off the coupler mounting and salvaging the sideframes to re-use the snap-in feature, but this results in sloppy truck location, and ultimately just retains a disappointing feature of these models. Nowadays trucks like this go straight into the trash. Only exception would be if I want to harvest the journal box covers to replace poorer ones on other trucks. In a couple of cases, I have harvested them, saved the covers in my “Trucks” parts drawer, then discarded the remains.

The way to fix the truck attachment is to fill the large bolster holes in the underframe, so that they can be drilled and tapped for your favorite truck screw (mine is 2-56). Then the correct coupler pad height needs to be checked, which I do by mounting the trucks and then comparing the height of the bottom of the car floor to the Kadee coupler height gauge (this height check is shown later in this post). If necessary, I then cut down or shim this location so that Kadee coupler boxes can be installed flat on the floor (normally with a 2-56 screw).

My favorite approach to filling that large hole in the bolster is as follows. I use Evergreen styrene 1/8-inch tubing, which is a little undersize, and shim it with 0.010 or 0.015-inch styrene sheet to fill the bolster hole. If the hole is larger still, I like Plastruct 4-mm styrene rod. I sometimes back this hole filler with a piece of styrene sheet on the inside of the floor, such as 0.060-inch thick, to ensure plenty of material for screws to thread into. I usually use Plastruct’s “Plastic Weld” cement for this job, as it really does weld the plastic parts together. Once dry, the tubing or rod can then be drilled all the way through, and tapped for 2-56 screws.

Here are two examples (models in progress for future posts).

This is a LifeLike one-piece reefer body. The bolster hole was filled with the 1/8-inch tubing, shimmed as needed to fill the hole, and then backfilled with modeling putty. The coupler pad shown is at about the right height but needed to be corrected (more on this in a moment).

Below is an AHM underbody, with both a large bolster hole for the snap-in trucks and a second large hole, which was created in molding the attachment for the car weight.

I filled the bolster hole with the tubing, and then a backing piece was added inside the car above the coupler pad, to ensure enough thread grip. Here are the corrected bolster holes, already tapped 2-56:

The backing pieces above the coupler location can be seen through the end-most holes.

I’m always surprised how many modelers who use the Kadee coupler height gauge don’t realize that the top of the back end of the same gauge is the height of a car floor correctly situated for installation of a Kadee coupler box. Shown below is the indication for one of the LifeLike reefer bodies, riding on its future trucks. It’s worth mentioning that the bolster height can vary from one model truck manufacturer to another, so this measurement needs to be done with the car’s intended trucks.

You can just see that the coupler pad cast onto the body needs to be removed to about the level of the floor. My typical modeling process would be to remove most of that coupler pad and re-check to be sure of the necessary height.

With the coupler pad all but removed, and trucks and couplers in place, the coupler height can be checked again with the Kadee gauge, as you see here, and it looks like it is right at the desired height. The car body (lettering mostly stripped) is ready for detailing.

Well, those are my techniques for replacing snap-in trucks and for installing the Kadee couplers on those car bodies. I have some upcoming posts which take advantage of these procedures in preparing a model.

Tony Thompson

These trucks largely had terrible wheelsets, poorly rendered side frames (the one shown above is better than average), and an unacceptable coupler arrangement.

When starting on an upgrade project for one of these cars, I have tried (in the distant past) cutting off the coupler mounting and salvaging the sideframes to re-use the snap-in feature, but this results in sloppy truck location, and ultimately just retains a disappointing feature of these models. Nowadays trucks like this go straight into the trash. Only exception would be if I want to harvest the journal box covers to replace poorer ones on other trucks. In a couple of cases, I have harvested them, saved the covers in my “Trucks” parts drawer, then discarded the remains.

The way to fix the truck attachment is to fill the large bolster holes in the underframe, so that they can be drilled and tapped for your favorite truck screw (mine is 2-56). Then the correct coupler pad height needs to be checked, which I do by mounting the trucks and then comparing the height of the bottom of the car floor to the Kadee coupler height gauge (this height check is shown later in this post). If necessary, I then cut down or shim this location so that Kadee coupler boxes can be installed flat on the floor (normally with a 2-56 screw).

My favorite approach to filling that large hole in the bolster is as follows. I use Evergreen styrene 1/8-inch tubing, which is a little undersize, and shim it with 0.010 or 0.015-inch styrene sheet to fill the bolster hole. If the hole is larger still, I like Plastruct 4-mm styrene rod. I sometimes back this hole filler with a piece of styrene sheet on the inside of the floor, such as 0.060-inch thick, to ensure plenty of material for screws to thread into. I usually use Plastruct’s “Plastic Weld” cement for this job, as it really does weld the plastic parts together. Once dry, the tubing or rod can then be drilled all the way through, and tapped for 2-56 screws.

Here are two examples (models in progress for future posts).

This is a LifeLike one-piece reefer body. The bolster hole was filled with the 1/8-inch tubing, shimmed as needed to fill the hole, and then backfilled with modeling putty. The coupler pad shown is at about the right height but needed to be corrected (more on this in a moment).

Below is an AHM underbody, with both a large bolster hole for the snap-in trucks and a second large hole, which was created in molding the attachment for the car weight.

I filled the bolster hole with the tubing, and then a backing piece was added inside the car above the coupler pad, to ensure enough thread grip. Here are the corrected bolster holes, already tapped 2-56:

The backing pieces above the coupler location can be seen through the end-most holes.

I’m always surprised how many modelers who use the Kadee coupler height gauge don’t realize that the top of the back end of the same gauge is the height of a car floor correctly situated for installation of a Kadee coupler box. Shown below is the indication for one of the LifeLike reefer bodies, riding on its future trucks. It’s worth mentioning that the bolster height can vary from one model truck manufacturer to another, so this measurement needs to be done with the car’s intended trucks.

You can just see that the coupler pad cast onto the body needs to be removed to about the level of the floor. My typical modeling process would be to remove most of that coupler pad and re-check to be sure of the necessary height.

With the coupler pad all but removed, and trucks and couplers in place, the coupler height can be checked again with the Kadee gauge, as you see here, and it looks like it is right at the desired height. The car body (lettering mostly stripped) is ready for detailing.

Well, those are my techniques for replacing snap-in trucks and for installing the Kadee couplers on those car bodies. I have some upcoming posts which take advantage of these procedures in preparing a model.

Tony Thompson

Friday, March 23, 2012

The bill box

In several prior posts about freight traffic and waybills, I have mentioned an institution called the “bill box.” One such post was about “The Role of the Agent,” at: http://modelingthesp.blogspot.com/2011/10/operations-role-of-agent.html .) This box was for the purpose of communication between an agent and conductors who worked that location, when the agent was off duty. It was a small box on the exterior of the depot, typically locked with a switch lock, sometimes painted the color of the depot walls, sometimes a contrasting color such as red.

The agent could leave messages directing the work of the local switch crew in this box, which a conductor would retrieve on arrival; and the agent would have put waybills and Empty Car Bills for outbound cars there too. The conductor would then place in the box any waybills for arriving loads his crew was going to spot, and the Empty Car Bills for any empties to be spotted. The next time the agent was on duty, of course, he or she would retrieve the contents of the bill box.

A bill box can sometimes be seen in photographs of depots from trackside. I will show a couple of SP examples here. Both photos are from the Shasta Division Archives, and I’ve added an arrow to indicate the bill box. First is the depot at Goleta, California, on the Coast Division:

The second image is the freight house at Gervais, Oregon (about three miles south of Woodburn), on the Portland Division, some 40 rail miles from Portland:

Both these boxes appear to be a contrasting color to the structure wall, though some other photos show a bill box seeming to match the wall color.

Given the above background, and my interest in the subject of freight paperwork and operations, perhaps you can understand my amazement, quickly followed by excitement, on seeing an actual SP bill box for sale at Winterail earlier this month (for a description of Winterail, you may go to: http://modelingthesp.blogspot.com/2012/03/winterail.html ). The seller did not even seem to have a price in mind (perhaps because of the full complement of original, prototype cobwebs inside the box), and we quickly struck a deal.

Of course, I immediately realized I would need an SP switch lock so I could accurately lock the box, and a switch key. Well, no better place to look for that kind of item than Winterail, and within minutes I had acquired both an SP lock and a matching key.

The box is fairly weathered and decrepit, but I’m tempted to leave it as-is, an authentic item relating to freight operations. Here it is, complete with SP switch lock.

The hasp on the bottom, of course, shows how the box was opened. Here is a view with the lid propped open:

Given the box, and knowing that waybills were exchanged between agent and conductor by this means, what else might have been in the box? Often the agent left directions to the crew. Here are a couple of examples which may be indicative of the general type of thing I’m describing. I must admit surprise at how detailed and explicit these comments are, and I assume they are comparable to what the agent would have told the conductor in person. First, a 1967 example from Dixon, Illinois, provided by Chet French, in which the agent directs exactly which cars to get at each location (you may click on the image to enlarge):

Every bit as explicit is this UP example, provided by Jeff Aley, from Hanna, Wyoming. It’s typed with upper and lower case and thus probably came from a conventional typewriter, not a billing typewriter (which typically could only produce upper case, as in the example above).

and interestingly, the following day the issue about the work cars has been solved:

I don’t think I or many other modelers are going to contemplate directions to crews this explicit, when a bill box is in use in an operating session, but it does mean that directions can be pretty direct without exaggerating reality. What more could you ask?

Tony Thompson

The agent could leave messages directing the work of the local switch crew in this box, which a conductor would retrieve on arrival; and the agent would have put waybills and Empty Car Bills for outbound cars there too. The conductor would then place in the box any waybills for arriving loads his crew was going to spot, and the Empty Car Bills for any empties to be spotted. The next time the agent was on duty, of course, he or she would retrieve the contents of the bill box.

A bill box can sometimes be seen in photographs of depots from trackside. I will show a couple of SP examples here. Both photos are from the Shasta Division Archives, and I’ve added an arrow to indicate the bill box. First is the depot at Goleta, California, on the Coast Division:

The second image is the freight house at Gervais, Oregon (about three miles south of Woodburn), on the Portland Division, some 40 rail miles from Portland:

Both these boxes appear to be a contrasting color to the structure wall, though some other photos show a bill box seeming to match the wall color.

Given the above background, and my interest in the subject of freight paperwork and operations, perhaps you can understand my amazement, quickly followed by excitement, on seeing an actual SP bill box for sale at Winterail earlier this month (for a description of Winterail, you may go to: http://modelingthesp.blogspot.com/2012/03/winterail.html ). The seller did not even seem to have a price in mind (perhaps because of the full complement of original, prototype cobwebs inside the box), and we quickly struck a deal.

Of course, I immediately realized I would need an SP switch lock so I could accurately lock the box, and a switch key. Well, no better place to look for that kind of item than Winterail, and within minutes I had acquired both an SP lock and a matching key.

The box is fairly weathered and decrepit, but I’m tempted to leave it as-is, an authentic item relating to freight operations. Here it is, complete with SP switch lock.

The hasp on the bottom, of course, shows how the box was opened. Here is a view with the lid propped open:

Given the box, and knowing that waybills were exchanged between agent and conductor by this means, what else might have been in the box? Often the agent left directions to the crew. Here are a couple of examples which may be indicative of the general type of thing I’m describing. I must admit surprise at how detailed and explicit these comments are, and I assume they are comparable to what the agent would have told the conductor in person. First, a 1967 example from Dixon, Illinois, provided by Chet French, in which the agent directs exactly which cars to get at each location (you may click on the image to enlarge):

Every bit as explicit is this UP example, provided by Jeff Aley, from Hanna, Wyoming. It’s typed with upper and lower case and thus probably came from a conventional typewriter, not a billing typewriter (which typically could only produce upper case, as in the example above).

and interestingly, the following day the issue about the work cars has been solved:

I don’t think I or many other modelers are going to contemplate directions to crews this explicit, when a bill box is in use in an operating session, but it does mean that directions can be pretty direct without exaggerating reality. What more could you ask?

Tony Thompson

Tuesday, March 20, 2012

Tank car placards: modeling

In the previous post on this topic, I showed the pre-1960 prototype placards which were in use during my modeling year of 1953 (see: http://modelingthesp.blogspot.com/2012/03/tank-car-placards-prototype.html ). This post addresses the question, how are these applied in modeling?

The first issue is to identify what placards go with which cargoes. This turns out to be easily found. The Appendix to Ed Kaminski’s book, Tank Cars, American Car & Foundry Company, 1865 to 1955 (Signature Press, 2003) lists cargoes and identifies their category. Here are the abbreviating initials for the categories:

Among these can be seen the categories corresponding to the placards shown in the previous post, such as flammable, Class A poison (Poison Gas placard), Class B poison (Poisonous placard), corrosive, and non-flammable compressed gas (Compressed Gas placard).

The second step is to look up a particular cargo in the body of this Appendix and see which cargo category it has. For example, the chemical consignee on my layout, Pacific Chemical Repackaging, receives methyl acetate in tank cars (it’s a low-toxicity solvent used in paint and some other products). Here is the entry for this material, in the Appendix just described (you can click on this item to enlarge it):

This table entry shows it is a Flammable Liquid and is often carried in ICC 103, 103W, 104 or 104W tank cars. So just like the petroleum products delivered to bulk oil plants, such as gasoline, kerosene, heating oil, and diesel fuel, it will carry an Inflammable placard when loaded. The same process can be repeated for any commodity to be transported in model form.

How should these placards be displayed on models? Obviously the loaded placard should be applied when the car is being delivered to a consignee, and the empty placard (if needed) should then be applied for movement of the empty car. One possibility is to apply the loaded placard to one side of the car, the empty placard to the other side. This could be a problem for layouts with reversing loops, because on those layouts, both sides of cars will be seen at different times, but on layouts like mine, where only one side of a car is ever seen (unless the car is physically rotated to show the other side), it works fine.

If different placards on each side of the car won’t work for you, maybe you can make a placard holder which can rotate in its mounting hole. Then the two needed placards would be applied to each side of each holder, and when the car is in service, the holders would simply be rotated to show the proper placard to match the waybill.

The former Proto2000 tank car models, now called WalthersProto, are delivered with Dangerous placards when they are in the form of ready-to-run models. These look fine, as can be seen in this photo of a Union Oil tank car on my layout. I need to place Empty placards on one side of such models.

Unfortunately, the availability out there of good model placards is limited. Here’s a brief summary from the viewpoint of a 1953 modeler like myself. The “correct” set is Microscale 87-975, but it’s currently out of stock (more on that in a moment). Microscale has two other sets for later years: 87-228, which is for the 1970s, and 87-840, which is for the 1980s. As I’ve said, these are entirely inappropriate for the 1950s. Sunshine no longer sells decal sets separately, except at some shows, but they have done a nice set called “Placards and Tags,” which can be used for a few of the needed tank car placards in HO scale.

What about Microscale 87-975? I contacted Microscale recently, and they do intend to reprint this set, but as they put it, it doesn’t have “a print date set as of when.” The set has a number of very useful placards, though some are printed all in red. Certainly some placards, such as the Inflammable placard, of which I showed a prototype, clearly says on its face which part is to be printed in red, and it is only the word “inflammable.” I don’t know what was the most common color for the various one-color placards. But the Microscale version of the Explosives, Dangerous, and Dangerous Empty placards appear correct, and a great many other placards for box and other car types are included too.

In the absence of this set, what else can you do? I have simply used images of the placards seen in the previous post (once again, here is the link: http://modelingthesp.blogspot.com/2012/03/tank-car-placards-prototype.html ), reduced them to HO scale (while correspondingly increasing the resolution), to about 0.175 actual inches across the diagonal of the diamond, and printed them on a laser printer. These can be glued to the placard holders on model tank cars (click to enlarge).

These placards readily show their distinctive shapes (doubtless an intent of their design), with the half-black Empty placard at left on the acid car, and the round-center Corrosive placard on the caustic soda car at right. (Construction of the acid car was described in Railroad Model Craftsman, January 2012, p. 61; see also my post at: http://modelingthesp.blogspot.com/2011/12/new-tank-car-article-in-rmc.html .) The Corrosive placard, shown here in black, seems to have been sometimes printed that way, and sometimes in red, as in the Microscale 87-975 set. Decals would be sharper than these laser-printed placards and I will probably make myself a decal set with some of these black placards at a future date.

This is far from exhausting the subject of model placards for tank cars, but it provides an introduction for now.

Tony Thompson

The first issue is to identify what placards go with which cargoes. This turns out to be easily found. The Appendix to Ed Kaminski’s book, Tank Cars, American Car & Foundry Company, 1865 to 1955 (Signature Press, 2003) lists cargoes and identifies their category. Here are the abbreviating initials for the categories:

Among these can be seen the categories corresponding to the placards shown in the previous post, such as flammable, Class A poison (Poison Gas placard), Class B poison (Poisonous placard), corrosive, and non-flammable compressed gas (Compressed Gas placard).

The second step is to look up a particular cargo in the body of this Appendix and see which cargo category it has. For example, the chemical consignee on my layout, Pacific Chemical Repackaging, receives methyl acetate in tank cars (it’s a low-toxicity solvent used in paint and some other products). Here is the entry for this material, in the Appendix just described (you can click on this item to enlarge it):

This table entry shows it is a Flammable Liquid and is often carried in ICC 103, 103W, 104 or 104W tank cars. So just like the petroleum products delivered to bulk oil plants, such as gasoline, kerosene, heating oil, and diesel fuel, it will carry an Inflammable placard when loaded. The same process can be repeated for any commodity to be transported in model form.

How should these placards be displayed on models? Obviously the loaded placard should be applied when the car is being delivered to a consignee, and the empty placard (if needed) should then be applied for movement of the empty car. One possibility is to apply the loaded placard to one side of the car, the empty placard to the other side. This could be a problem for layouts with reversing loops, because on those layouts, both sides of cars will be seen at different times, but on layouts like mine, where only one side of a car is ever seen (unless the car is physically rotated to show the other side), it works fine.

If different placards on each side of the car won’t work for you, maybe you can make a placard holder which can rotate in its mounting hole. Then the two needed placards would be applied to each side of each holder, and when the car is in service, the holders would simply be rotated to show the proper placard to match the waybill.

The former Proto2000 tank car models, now called WalthersProto, are delivered with Dangerous placards when they are in the form of ready-to-run models. These look fine, as can be seen in this photo of a Union Oil tank car on my layout. I need to place Empty placards on one side of such models.

Unfortunately, the availability out there of good model placards is limited. Here’s a brief summary from the viewpoint of a 1953 modeler like myself. The “correct” set is Microscale 87-975, but it’s currently out of stock (more on that in a moment). Microscale has two other sets for later years: 87-228, which is for the 1970s, and 87-840, which is for the 1980s. As I’ve said, these are entirely inappropriate for the 1950s. Sunshine no longer sells decal sets separately, except at some shows, but they have done a nice set called “Placards and Tags,” which can be used for a few of the needed tank car placards in HO scale.

What about Microscale 87-975? I contacted Microscale recently, and they do intend to reprint this set, but as they put it, it doesn’t have “a print date set as of when.” The set has a number of very useful placards, though some are printed all in red. Certainly some placards, such as the Inflammable placard, of which I showed a prototype, clearly says on its face which part is to be printed in red, and it is only the word “inflammable.” I don’t know what was the most common color for the various one-color placards. But the Microscale version of the Explosives, Dangerous, and Dangerous Empty placards appear correct, and a great many other placards for box and other car types are included too.

In the absence of this set, what else can you do? I have simply used images of the placards seen in the previous post (once again, here is the link: http://modelingthesp.blogspot.com/2012/03/tank-car-placards-prototype.html ), reduced them to HO scale (while correspondingly increasing the resolution), to about 0.175 actual inches across the diagonal of the diamond, and printed them on a laser printer. These can be glued to the placard holders on model tank cars (click to enlarge).

These placards readily show their distinctive shapes (doubtless an intent of their design), with the half-black Empty placard at left on the acid car, and the round-center Corrosive placard on the caustic soda car at right. (Construction of the acid car was described in Railroad Model Craftsman, January 2012, p. 61; see also my post at: http://modelingthesp.blogspot.com/2011/12/new-tank-car-article-in-rmc.html .) The Corrosive placard, shown here in black, seems to have been sometimes printed that way, and sometimes in red, as in the Microscale 87-975 set. Decals would be sharper than these laser-printed placards and I will probably make myself a decal set with some of these black placards at a future date.

This is far from exhausting the subject of model placards for tank cars, but it provides an introduction for now.

Tony Thompson

Sunday, March 18, 2012

Tank car placards: prototype

One of the items I discovered at Winterail this year was a vintage tank car placard. It is reproduced below. (For a description of the annual Winterail meeting, you may wish to read my post on the subject, which is at: http://modelingthesp.blogspot.com/2012/03/winterail.html .) I did purchase it, since luckily it was not very expensive.

Before talking about individual placards, I should point out that the idea behind placards is to ensure that anyone who has to move or unload a car containing dangerous material will know what that material is, and be aware of what cautions are appropriate. This applies to many loads in tank cars, but can apply to any car type.

The placard I bought at Winterail was produced by the St. Louis-San Francisco Railway, and it has a “document date” on it of April 1962. As a standard placard, it is 10-3/4 inches on a side, which fits a tank car placard holder. Note that below the word “Dangerous” is a space to write in the particular cargo.

The immediate question which presented itself was, would this be applicable to my modeling? Or, a bit more generally stated, what placards are applicable to my modeling, and why?

Luckily for modelers, there is an authoritative and complete magazine article on this subject, by John Ryczkowski, in Mainline Modeler (Volume 14, January 1993, pages 68–73). John clearly describes the various placards of different eras, and makes clear that my modeling year of 1953 was very different from more recent years. Any modern modeler reading this post can find detailed descriptions and images of contemporary practice all over the Internet, but for older material, you’ll pretty much have to consult John’s article.

One big watershed to recognize: in November 1981 the U.S. Dept. of Transportation adopted the United Nations world-wide system of numbers to identify classes of hazardous materials. These UN numbers, ranging from 1 to 9, are at the bottom tip of more modern placards and readily distinguish post-1981 placards from older ones.

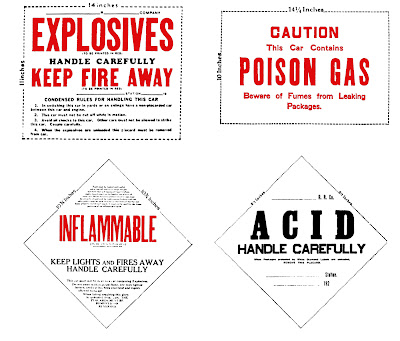

So what about the history? I will abstract a brief description from John’s article and show a few examples. Placards were in use at least as early as the start of the 20th century. However, statutory placard requirements began in 1921, in an amendment to the 1920 Transportation Act, granting regulatory power to the ICC to ensure safe transportation of dangerous materials. There were four original placards:

At top left is the Explosives placard, with critical words printed in red. Next to it is the Poison Gas placard, all in red, and at lower left is the Inflammable placard (in those days, “flammable” and “inflammable” were synonyms; today only the word “flammable” is used, to avoid confusion, or over-thinking of the problem). The Acid placard was smaller and could be pasted onto placard boards or even directly onto the tank itself. In this era, possibly dangerous empty cars were indicated by simply reversing the placard for the former load, showing its blank side rather than an empty placard board.

These placards remained in use into the 1950s. Here is a photo, courtesy Bruce Petty, of a box car with an Explosives placard on the door (photo dates from 1956). Though placards for dangerous materials are primarily associated with tank cars, it must be remembered that they were used for any car type if needed.

In 1930, additional placard categories were added, with the original four remaining in use. Here are the ones added in 1930. All are 10-3/4 inches square.

The Corrosive Liquid placard was for corrosive materials other than acids. The Compressed Gas placard is self-explanatory. The new Poisonous placard was for materials less dangerous than the Poison Gas category, which is to say, harmful materials, but not immediately threatening to life. Finally, since several of these material categories remain dangerous even as residue in a nominally empty car, the Dangerous Empty placard, half black, was introduced. This provided positive information, compared to simply reversing the placard for the former load.

During the 1930s, and certainly prior to World War II, a new Dangerous placard was introduced, much like the one I acquired at Winterail, suitable for a variety of cargoes, and having an area to write in the particular cargo. Here is a wartime photo, from the Office of War Information, of such a placard being added to a tank car. Note that to the right of the workman is an Empty indication, made by folding down the previous placard. Probably the workman is going to add a new Dangerous placard to that placard holder also.

In 1960, a number of important changes to placards were made, including creation of more of a family resemblance among them, and increased use of color. But major changes did not occur until 1974. So modelers of pre-1974 railroading, and even more so for pre-1960 modeling, have considerably different placards to consider.

As I will show in the second post on this topic, “Modeling,” these dates are not merely dry history, but help to indicate the various decal and other model placards which are useful for different modeling eras.

Tony Thompson

Before talking about individual placards, I should point out that the idea behind placards is to ensure that anyone who has to move or unload a car containing dangerous material will know what that material is, and be aware of what cautions are appropriate. This applies to many loads in tank cars, but can apply to any car type.

The placard I bought at Winterail was produced by the St. Louis-San Francisco Railway, and it has a “document date” on it of April 1962. As a standard placard, it is 10-3/4 inches on a side, which fits a tank car placard holder. Note that below the word “Dangerous” is a space to write in the particular cargo.

The immediate question which presented itself was, would this be applicable to my modeling? Or, a bit more generally stated, what placards are applicable to my modeling, and why?

Luckily for modelers, there is an authoritative and complete magazine article on this subject, by John Ryczkowski, in Mainline Modeler (Volume 14, January 1993, pages 68–73). John clearly describes the various placards of different eras, and makes clear that my modeling year of 1953 was very different from more recent years. Any modern modeler reading this post can find detailed descriptions and images of contemporary practice all over the Internet, but for older material, you’ll pretty much have to consult John’s article.

One big watershed to recognize: in November 1981 the U.S. Dept. of Transportation adopted the United Nations world-wide system of numbers to identify classes of hazardous materials. These UN numbers, ranging from 1 to 9, are at the bottom tip of more modern placards and readily distinguish post-1981 placards from older ones.

So what about the history? I will abstract a brief description from John’s article and show a few examples. Placards were in use at least as early as the start of the 20th century. However, statutory placard requirements began in 1921, in an amendment to the 1920 Transportation Act, granting regulatory power to the ICC to ensure safe transportation of dangerous materials. There were four original placards:

At top left is the Explosives placard, with critical words printed in red. Next to it is the Poison Gas placard, all in red, and at lower left is the Inflammable placard (in those days, “flammable” and “inflammable” were synonyms; today only the word “flammable” is used, to avoid confusion, or over-thinking of the problem). The Acid placard was smaller and could be pasted onto placard boards or even directly onto the tank itself. In this era, possibly dangerous empty cars were indicated by simply reversing the placard for the former load, showing its blank side rather than an empty placard board.

These placards remained in use into the 1950s. Here is a photo, courtesy Bruce Petty, of a box car with an Explosives placard on the door (photo dates from 1956). Though placards for dangerous materials are primarily associated with tank cars, it must be remembered that they were used for any car type if needed.

In 1930, additional placard categories were added, with the original four remaining in use. Here are the ones added in 1930. All are 10-3/4 inches square.

The Corrosive Liquid placard was for corrosive materials other than acids. The Compressed Gas placard is self-explanatory. The new Poisonous placard was for materials less dangerous than the Poison Gas category, which is to say, harmful materials, but not immediately threatening to life. Finally, since several of these material categories remain dangerous even as residue in a nominally empty car, the Dangerous Empty placard, half black, was introduced. This provided positive information, compared to simply reversing the placard for the former load.

During the 1930s, and certainly prior to World War II, a new Dangerous placard was introduced, much like the one I acquired at Winterail, suitable for a variety of cargoes, and having an area to write in the particular cargo. Here is a wartime photo, from the Office of War Information, of such a placard being added to a tank car. Note that to the right of the workman is an Empty indication, made by folding down the previous placard. Probably the workman is going to add a new Dangerous placard to that placard holder also.

In 1960, a number of important changes to placards were made, including creation of more of a family resemblance among them, and increased use of color. But major changes did not occur until 1974. So modelers of pre-1974 railroading, and even more so for pre-1960 modeling, have considerably different placards to consider.

As I will show in the second post on this topic, “Modeling,” these dates are not merely dry history, but help to indicate the various decal and other model placards which are useful for different modeling eras.

Tony Thompson

Friday, March 16, 2012

Waybills, Part 20: other approaches

There have been several modelers around the country in the last few years who have been experimenting with ways to do model waybills in more prototypical fashion. I am one of those, and have been describing my results in a number of posts to this blog, of which this is the 20th. Those prior posts are readily identified in the archive of this blog by the thread title, “Waybills.”

One notable discussion of choosing a waybill system and experimenting with details is that by Bob Sterner, for his Soo Line layout. Bob is planning to use a somewhat different format than mine, and has usefully described the thought process behind his choices so far. He does use a clear “car sleeve” like the ones I’ve described. Several of his posts can be found at this link: https://sites.google.com/a/bobsworkbench.com/bobsworkbench/operations/layout-waybills .

In a similar vein, Frank Hodina is choosing to make a large waybill, about 4 inches square, which will be folded in half–as were prototype bills in many cases–and then placed in the same kind of 2 x 4-inch sleeve which a number of modelers are using, and which I’ve described for Otis McGee’s layout (see: http://modelingthesp.blogspot.com/2011/07/waybills-9.html ). At one stroke this provides more space for information, and duplicates the prototype arrangement of the center fold of the document.

Here is an example of Frank’s waybill, which is prepared in Microsoft Excel. He has a coding box in the upper left to help crews get cars into the right trains (and to the right sidings). It can be compared to the prototype waybill I showed in an earlier post, at http://modelingthesp.blogspot.com/2011/02/waybills-4.html .

In my view, this is an extremely realistic waybill. But when folded in half, the crew will be even more unlikely than ever to look at the information on the right half of the bill. It’s an individual choice if this is seen as a drawback.

Many readers of this blog will have seen Ted Pamperin’s fine article in Model Railroader, in the issue for February 2012 (page 45). Ted not only describes the system he, Tony Koester, and others in the New Jersey area are using, but provides a number of very interesting details on how the Chesapeake & Ohio (Ted’s prototype) handled the complexities of coal traffic. Ted is the person who first found the very useful 2 x 4-inch side-entry sleeves many people are using. He has also done a fine job of compactly describing the intent and implementation of a prototype bill system. Ted gives outstanding talks at modeling meetings, and they are well worth your time if you find one on the schedule of a meeting you’re attending.

I do have some minor issues with what Ted describes. I personally don’t like the non-prototypical inclusion in Ted’s waybill of directions identifying the siding at which a car is to be set out. I also disagree with his use of lower case letters when prototype waybills of his era were all upper case, and I suspect he has already corrected that feature. But those are details, and overall, I highly recommend this article for anyone with any interest in the current movement toward more prototypical waybills.

In an earlier post giving comments about last fall’s meeting at Lisle, Illinois, I summarized an outstanding talk by Dan Holbrook, and a fine accompanying talk by Perry Sugarman. (My summary can be viewed at: http://modelingthesp.blogspot.com/2011/10/meeting-highlights-lisle.html .) Dan’s waybills are a little larger than most, and somewhat resemble the Frank Hodina version shown above. My understanding is that Dan plans to write an article about his current waybill system, so I won’t go further into detail here.

These are not the only “alternative waybills” out there, but these should give a flavor of some thing that are being explored. As more come to light, I will post about them.

Tony Thompson

One notable discussion of choosing a waybill system and experimenting with details is that by Bob Sterner, for his Soo Line layout. Bob is planning to use a somewhat different format than mine, and has usefully described the thought process behind his choices so far. He does use a clear “car sleeve” like the ones I’ve described. Several of his posts can be found at this link: https://sites.google.com/a/bobsworkbench.com/bobsworkbench/operations/layout-waybills .

In a similar vein, Frank Hodina is choosing to make a large waybill, about 4 inches square, which will be folded in half–as were prototype bills in many cases–and then placed in the same kind of 2 x 4-inch sleeve which a number of modelers are using, and which I’ve described for Otis McGee’s layout (see: http://modelingthesp.blogspot.com/2011/07/waybills-9.html ). At one stroke this provides more space for information, and duplicates the prototype arrangement of the center fold of the document.

Here is an example of Frank’s waybill, which is prepared in Microsoft Excel. He has a coding box in the upper left to help crews get cars into the right trains (and to the right sidings). It can be compared to the prototype waybill I showed in an earlier post, at http://modelingthesp.blogspot.com/2011/02/waybills-4.html .

Many readers of this blog will have seen Ted Pamperin’s fine article in Model Railroader, in the issue for February 2012 (page 45). Ted not only describes the system he, Tony Koester, and others in the New Jersey area are using, but provides a number of very interesting details on how the Chesapeake & Ohio (Ted’s prototype) handled the complexities of coal traffic. Ted is the person who first found the very useful 2 x 4-inch side-entry sleeves many people are using. He has also done a fine job of compactly describing the intent and implementation of a prototype bill system. Ted gives outstanding talks at modeling meetings, and they are well worth your time if you find one on the schedule of a meeting you’re attending.

I do have some minor issues with what Ted describes. I personally don’t like the non-prototypical inclusion in Ted’s waybill of directions identifying the siding at which a car is to be set out. I also disagree with his use of lower case letters when prototype waybills of his era were all upper case, and I suspect he has already corrected that feature. But those are details, and overall, I highly recommend this article for anyone with any interest in the current movement toward more prototypical waybills.

In an earlier post giving comments about last fall’s meeting at Lisle, Illinois, I summarized an outstanding talk by Dan Holbrook, and a fine accompanying talk by Perry Sugarman. (My summary can be viewed at: http://modelingthesp.blogspot.com/2011/10/meeting-highlights-lisle.html .) Dan’s waybills are a little larger than most, and somewhat resemble the Frank Hodina version shown above. My understanding is that Dan plans to write an article about his current waybill system, so I won’t go further into detail here.

These are not the only “alternative waybills” out there, but these should give a flavor of some thing that are being explored. As more come to light, I will post about them.

Tony Thompson

Tuesday, March 13, 2012

Winterail

Last Saturday, March 10, was the annual meeting in Northern California called Winterail (supposedly named by analogy with the famed drag racing competition called the Winternationals). It started in the late 1970s with a small number of avid rail photographers who got together to look at each other’s slides, in the early years in motel rooms. Of course, the 35 mm slides of former years have given way to digital presentations. Today the meeting is held at the Masonic Center in Stockton, where the meet has taken place for most of the last 20 years, and because of the auditorium size, attendance has to be limited to 1000 people (give or take).

This year was the 34th Winterail in succession. For years, Dave Stanley, later with the help of Ken Meeker, was the producer, while today Vic Neves and Cheryl Meeker handle the duty, with the help of a considerable additional staff and a team of roadies. The same logo has been used for many years, originally created by John Signor and now the iconic emblem of the event.

Over the years, many of the great rail photographers of the nation, not just the West, have presented at Winterail, though the emphasis is definitely western. This year was no exception, with Dick Dorn, Tom Gildersleeve, and Mike Danneman among the presenters, and Stan Kistler narrating a presentation of photographs by the late Al Rose. The presentation quality is dauntingly high every year, and for many railfans, these shows, starting at noon, are the core of Winterail.

But there are also world-class railroadiana sales rooms, starting at 9 AM, where everything from railroad photos, paper and books, to complete Mars lights or semaphore blades, are for sale. I have built most of my collection of SP employee timetables and other documents from sales tables at Winterail, and have often found other valuable items, particularly photos.

An important aspect for many of us is the camaraderie. This is a gathering of many, many railfans, railroad historians, and modelers from much of the west coast, and in many cases a chance to see old friends that one doesn’t see elsewhere. I have been attending now for almost 25 years, and it never has come close to getting stale for me.

There is a sampling of photos from various aspects of Winterail on their web site (though not from the current year); you can view them at this link: http://www.winterail.com/Winterail_Pictures.html .

This year, in addition to some useful books, I found a couple of items which fit perfectly into some blog subjects I had been toying with, so those posts will be coming along shortly. For me, Winterail is one of those events that is foremost on the annual calendar, and it would take a pretty major competing event for me to miss it. If you’ve never attended, consider it for next year. It is always on the second full weekend in March, so it will be Saturday, March 9, 2013.

Tony Thompson

This year was the 34th Winterail in succession. For years, Dave Stanley, later with the help of Ken Meeker, was the producer, while today Vic Neves and Cheryl Meeker handle the duty, with the help of a considerable additional staff and a team of roadies. The same logo has been used for many years, originally created by John Signor and now the iconic emblem of the event.

Over the years, many of the great rail photographers of the nation, not just the West, have presented at Winterail, though the emphasis is definitely western. This year was no exception, with Dick Dorn, Tom Gildersleeve, and Mike Danneman among the presenters, and Stan Kistler narrating a presentation of photographs by the late Al Rose. The presentation quality is dauntingly high every year, and for many railfans, these shows, starting at noon, are the core of Winterail.

But there are also world-class railroadiana sales rooms, starting at 9 AM, where everything from railroad photos, paper and books, to complete Mars lights or semaphore blades, are for sale. I have built most of my collection of SP employee timetables and other documents from sales tables at Winterail, and have often found other valuable items, particularly photos.

An important aspect for many of us is the camaraderie. This is a gathering of many, many railfans, railroad historians, and modelers from much of the west coast, and in many cases a chance to see old friends that one doesn’t see elsewhere. I have been attending now for almost 25 years, and it never has come close to getting stale for me.

There is a sampling of photos from various aspects of Winterail on their web site (though not from the current year); you can view them at this link: http://www.winterail.com/Winterail_Pictures.html .

This year, in addition to some useful books, I found a couple of items which fit perfectly into some blog subjects I had been toying with, so those posts will be coming along shortly. For me, Winterail is one of those events that is foremost on the annual calendar, and it would take a pretty major competing event for me to miss it. If you’ve never attended, consider it for next year. It is always on the second full weekend in March, so it will be Saturday, March 9, 2013.

Tony Thompson

Monday, March 12, 2012

Open-car loads: crates and machinery

A common flat car or gondola load is the large crate or item of machinery which is too large to load through a boxcar door. Crates are easy to make and can represent a very wide variety of cargoes, from assembled automobiles to machine tools to replacement parts of any kind.

In the 1950s, some machinery might be shipped without a crate, especially if it was “outdoor” equipment which wouldn’t be harmed by a little rain. Non-crated machinery might well be covered with a tarpaulin, but this is not easy to model convincingly. Most modelers have seen the commercial cast resin versions, in which the tarp looks like it is stretched as tight as a drum head. I don’t know if prototype tarped loads are ever done that way, but I have never seen one like that. Instead, tarps are loosely gathered and nailed or tied down around the load. My experiments in reproducing this kind of appearance with paint-saturated facial tissue have been only mildly successful, so I won’t address those here.

I will begin with a cast metal diesel engine. These were painted yellow and I attached a Caterpillar sign. All or nearly all of my open-car loads are removable so that cars can run empty as well as loaded. With these engines, I noticed that they tended not to remain straight on the flat car deck when simply placed there, even though they are fairly heavy, so I added a “locator” strip. This is a thin brass strip, glued beneath the load supports, which drops into the car’s stake pockets. When painted black, it is all but invisible. Here’s an end view of it; note the end bracing on the end of the engine frame.

Here is a pair of these engines on a flat car. The only drawback to this method is that the width across model flat cars is not always consistent, and this kind of locator may not work for all the flat cars in your fleet.

Crates are more commonly used than uncovered loads of machinery. Protection from weather or theft is one reason; multiple parts in one crate is another. (It was common for uncovered machinery to be accompanied by one or more crates of additional parts.) Prototype crates come in all styles and sizes, and may be made from a variety of materials.

I will just show a few examples of crates on my layout. Since my track plan has no reversing loop, all cars always show the same side to the operator/observer (unless physically reversed in staging). That means that crates might as well have different information or logos on each side, providing two loads (according to waybills) for each one built. This is one of them; I’ll show the Allis-Chalmers side first.

Here is the other side, with info for Wagner mining machinery. I made color copies of actual logos from ads in old mining journals for the signs on these cars. This crate fits either flat cars or gondolas.

Here is a different crate, again with two sides (this crate will only fit on a flat car, and has a brass-strip “locator” on it, as I described above for the Cat engines–it should be easy to spot). The first side advertises the Fort Worth Steel and Machinery firm (a maker of oil-field equipment):

The other side shows a logo for Hardinge Company mineral processing equipment (other products then included lathes and other metalworking equipment):

An inspiring example comes from modeler John Golden. This load of metal or plywood containers (no two alike), painted and addressed to the U.S. Navy Supply Center, Norfolk, VA, looks realistic and would be easy to make from styrene. I plan to make one or more loads like these, and will arrange the tie-downs so the loads are removable. John’s load on this car is in fact a commercial resin product, from Sunshine (Sunshine called it the “Overseas Crates” load, now out of production), but I include it because it would be a simple matter to do the same from scratch. The flat car is Tichy (John tells me that its car number needs to be corrected), and John took the photo.

These examples can easily be multiplied, but I think the point is evident, that this kind of load is simple to make and effective in use.

Other than John Golden’s load photo, I haven’t included commercial loads in this post, but may do that in a future post, because there are some good ones available. Since that seems to me like a separate subject, I will treat it that way. In the meantime, consider making a couple of simple crates for your open-top cars.

Tony Thompson

In the 1950s, some machinery might be shipped without a crate, especially if it was “outdoor” equipment which wouldn’t be harmed by a little rain. Non-crated machinery might well be covered with a tarpaulin, but this is not easy to model convincingly. Most modelers have seen the commercial cast resin versions, in which the tarp looks like it is stretched as tight as a drum head. I don’t know if prototype tarped loads are ever done that way, but I have never seen one like that. Instead, tarps are loosely gathered and nailed or tied down around the load. My experiments in reproducing this kind of appearance with paint-saturated facial tissue have been only mildly successful, so I won’t address those here.

I will begin with a cast metal diesel engine. These were painted yellow and I attached a Caterpillar sign. All or nearly all of my open-car loads are removable so that cars can run empty as well as loaded. With these engines, I noticed that they tended not to remain straight on the flat car deck when simply placed there, even though they are fairly heavy, so I added a “locator” strip. This is a thin brass strip, glued beneath the load supports, which drops into the car’s stake pockets. When painted black, it is all but invisible. Here’s an end view of it; note the end bracing on the end of the engine frame.

Crates are more commonly used than uncovered loads of machinery. Protection from weather or theft is one reason; multiple parts in one crate is another. (It was common for uncovered machinery to be accompanied by one or more crates of additional parts.) Prototype crates come in all styles and sizes, and may be made from a variety of materials.

I will just show a few examples of crates on my layout. Since my track plan has no reversing loop, all cars always show the same side to the operator/observer (unless physically reversed in staging). That means that crates might as well have different information or logos on each side, providing two loads (according to waybills) for each one built. This is one of them; I’ll show the Allis-Chalmers side first.

Here is the other side, with info for Wagner mining machinery. I made color copies of actual logos from ads in old mining journals for the signs on these cars. This crate fits either flat cars or gondolas.

Here is a different crate, again with two sides (this crate will only fit on a flat car, and has a brass-strip “locator” on it, as I described above for the Cat engines–it should be easy to spot). The first side advertises the Fort Worth Steel and Machinery firm (a maker of oil-field equipment):

The other side shows a logo for Hardinge Company mineral processing equipment (other products then included lathes and other metalworking equipment):

An inspiring example comes from modeler John Golden. This load of metal or plywood containers (no two alike), painted and addressed to the U.S. Navy Supply Center, Norfolk, VA, looks realistic and would be easy to make from styrene. I plan to make one or more loads like these, and will arrange the tie-downs so the loads are removable. John’s load on this car is in fact a commercial resin product, from Sunshine (Sunshine called it the “Overseas Crates” load, now out of production), but I include it because it would be a simple matter to do the same from scratch. The flat car is Tichy (John tells me that its car number needs to be corrected), and John took the photo.

These examples can easily be multiplied, but I think the point is evident, that this kind of load is simple to make and effective in use.

Other than John Golden’s load photo, I haven’t included commercial loads in this post, but may do that in a future post, because there are some good ones available. Since that seems to me like a separate subject, I will treat it that way. In the meantime, consider making a couple of simple crates for your open-top cars.

Tony Thompson

Friday, March 9, 2012

Distressing gondolas

I received an interesting e-mail, asking about the distressed top chord in my model of the Pennsylvania 65-foot mill gondola (class G26), from the E&B Valley kit, shown in my post on long gondola loads (available at: http://modelingthesp.blogspot.com/2012/03/open-car-loads-poles-and-girders-in.html ). The question was about the distressing method and results.

The model was assembled pretty much as E&B Valley directed, but the car, if built stock, rides much too high above the trucks. This was noted in the original reviews of this kit in both Model Railroader (August 1981, pp. 44-48) and Railroad Model Craftsman (November 1981, pp. 101-105), and the obvious corrections were shown. I followed these suggestions. This E&B Valley kit was later sold under the name “Eastern Car Works” and is often seen at swap meets.

I removed the kit’s coupler pocket from the center sill and sanded down the coupler pad on the floor, so I could install a Kadee coupler box flush with the car floor. I also cut down the truck bolster nearly to the level of the side sill. This resulted in a more realistic car height. If you’d like to read a fuller account of how to do these modifications as well as additional detailing, an excellent source is Elden Gatwood’s article in the electronic magazine, the Keystone Modeler, issue No. 9, page 32. You can access it at: http://www.prrths.com/Keystone%20Modeler/Keystone_Modeler.htm .

Now to the distressing of the car sides. I have tried two methods with plastic freight cars like this gondola. One is to warm the car side with a nearby but not touching (and hot) soldering iron, then using the sides of a nail or screwdriver to press the top chord outward or inward. A second method tried was to use a hair dryer, instead the soldering iron. The first method is good at softening local areas only, if you want a very local irregularity, but care is definitely needed not to touch the model with the iron (don’t ask how I know). The second method heats a bigger area, and it can be too easy to make major bends in the car side, but you have a little more scope in what you do.

Here is a top view of the Pennsy gondola, and if you click to enlarge the image, you can see all the various bends and dents.

These bends are probably too gentle, compared to what happens to prototype cars when subjected to abusive loading, but in HO scale they look all right. Here are some close-ups of the same car sides:

The car is represented as fairly recently repainted, thus the weathering is not very extensive, on either sides or interior, but a more heavily distressed and dirty interior would probably be more realistic.

I haven’t done this process to that many of my steel gondolas, and would suggest that as long as you have at least some of your cars distressed, the “look” of your fleet will be improved. But if I were modeling a steel mill, where abusive loading of heavy steel shapes was practically a daily occurrence, I would want to show a lot more damage in these cars.

A friend in the days I lived in Pittsburgh told of having worked, when he was a teenager, as a crane man in one of the area mills, and watching the experienced crane operators vying to see who could make the structural shapes bounce the highest when dropped into gondolas. I would guess it is hard for modelers to exaggerate the resulting damage to cars.

Tony Thompson

The model was assembled pretty much as E&B Valley directed, but the car, if built stock, rides much too high above the trucks. This was noted in the original reviews of this kit in both Model Railroader (August 1981, pp. 44-48) and Railroad Model Craftsman (November 1981, pp. 101-105), and the obvious corrections were shown. I followed these suggestions. This E&B Valley kit was later sold under the name “Eastern Car Works” and is often seen at swap meets.

I removed the kit’s coupler pocket from the center sill and sanded down the coupler pad on the floor, so I could install a Kadee coupler box flush with the car floor. I also cut down the truck bolster nearly to the level of the side sill. This resulted in a more realistic car height. If you’d like to read a fuller account of how to do these modifications as well as additional detailing, an excellent source is Elden Gatwood’s article in the electronic magazine, the Keystone Modeler, issue No. 9, page 32. You can access it at: http://www.prrths.com/Keystone%20Modeler/Keystone_Modeler.htm .

Now to the distressing of the car sides. I have tried two methods with plastic freight cars like this gondola. One is to warm the car side with a nearby but not touching (and hot) soldering iron, then using the sides of a nail or screwdriver to press the top chord outward or inward. A second method tried was to use a hair dryer, instead the soldering iron. The first method is good at softening local areas only, if you want a very local irregularity, but care is definitely needed not to touch the model with the iron (don’t ask how I know). The second method heats a bigger area, and it can be too easy to make major bends in the car side, but you have a little more scope in what you do.

Here is a top view of the Pennsy gondola, and if you click to enlarge the image, you can see all the various bends and dents.

These bends are probably too gentle, compared to what happens to prototype cars when subjected to abusive loading, but in HO scale they look all right. Here are some close-ups of the same car sides:

The car is represented as fairly recently repainted, thus the weathering is not very extensive, on either sides or interior, but a more heavily distressed and dirty interior would probably be more realistic.

I haven’t done this process to that many of my steel gondolas, and would suggest that as long as you have at least some of your cars distressed, the “look” of your fleet will be improved. But if I were modeling a steel mill, where abusive loading of heavy steel shapes was practically a daily occurrence, I would want to show a lot more damage in these cars.

A friend in the days I lived in Pittsburgh told of having worked, when he was a teenager, as a crane man in one of the area mills, and watching the experienced crane operators vying to see who could make the structural shapes bounce the highest when dropped into gondolas. I would guess it is hard for modelers to exaggerate the resulting damage to cars.

Tony Thompson

Tuesday, March 6, 2012

Open-car loads: poles and girders in gondolas

The loading of poles and girders in gondolas follows the ideas already shown for lumber in gondolas, if the load is stacked and extends above the sides of the gondola. The interesting exceptions are girders shipped on edge, which I’ll describe in this post. But first I will show a pole load I use.

Many modelers will have heard of the idea to use chopsticks from Chinese restaurants, appropriately re-tapered if necessary, and stained a very dark brownish-black to represent creosoted poles. I’ve done that in some cases, but I have also used simple dowel, since not all poles are strongly tapered. My choice here was a 5/32-inch dowel, probably a little on the slender side, but photos do show some “city” poles of this approximate size.

My load was originally created for the very first Sunshine resin kit, numbered kit no. 1.1, for a Missouri Pacific panel-side 45-foot gondola. (I reviewed it for Railroad Model Craftsman in January, 1990, p. 104). The car sides in the kit were not modeled with the indentations on the interior which should be present in a panel-side car, so I wanted to make a load which would pretty well fill the car and hide the lack of a correct interior contour, while remaining removable. This is the loose load of dowels in the car:

Girders make an interesting and relatively easy load for gondolas (or flat cars). The old Atlas styrene through-girder bridge is a cheap and easy source of girders, which can also be kitbashed to greater or lesser lengths as desired. I just cut the sides away from the deck and proceed. If they need to be lengthened, I make an overlay strip of 0.005-inch styrene (approximately matching the ones already on the Atlas molding) to cover the joint. I used to impress rivets into such strips with a scriber, but now Archer rivets are a much easier and better-looking alternative (if you don’t already know this product, visit http://www.archertransfers.com/SurfaceDetailsMain.html .

Here is one such lengthened girder, as a load in the Athearn mill gondola. It is sufficiently long that the working end doors of the gondola need to be dropped to accept this load.

As you can see, I painted the girder a bright oxide red, like the color used on Union Pacific or Pennsylvania freight cars, which is like the “rustproof” paint used on steel assemblies. I used a Bethlehem Steel logo from an old magazine ad to adorn the girder.

Of course, girders like this might be painted in the final color to be used when they were installed as part of a bridge. I represented that in a different girder load, with aluminum paint, and another possibility would be black. Here is my silver girder, with a Jones & Laughlin Steel logo:

The gondola is a reworked E&B Valley model, representing PRR Class G26, with some distressing of the top chord with a heat gun. The girder has a low bracing arrangement which should probably be replaced by something like the bracing in this next project, a short girder.

My shorter girder was built from Atlas bridge remnants, and I have arranged it so it can be loaded on either a gondola or flat car. A girder this size might equally likely be loaded flat, but I have arranged it for loading on edge. Most of the Loading Rules diagrams for such loading are for loads across two or more cars, but they have in common diagonal braces on each side of the load (somewhat as shown above for the long Bethlehem girder), as in this drawing from the 1926 Rules:

I used scale 6 x 6-inch stripwood for the bracing, with a strip of styrene scale 1 x 6-inch for the iron top strap (angled bends like these in styrene strip can be made with care), which I painted medium gray.

You can see in this view that I added flanges with holes for future rivet or bolt assembly on each end of this short girder. When in a gondola (this is a Detail Associates model), this load looks this way:

There are lots more long-load ideas in the Loading Rules books, and they are fun to build as well as fun to operate on the layout.

Tony Thompson

Many modelers will have heard of the idea to use chopsticks from Chinese restaurants, appropriately re-tapered if necessary, and stained a very dark brownish-black to represent creosoted poles. I’ve done that in some cases, but I have also used simple dowel, since not all poles are strongly tapered. My choice here was a 5/32-inch dowel, probably a little on the slender side, but photos do show some “city” poles of this approximate size.

My load was originally created for the very first Sunshine resin kit, numbered kit no. 1.1, for a Missouri Pacific panel-side 45-foot gondola. (I reviewed it for Railroad Model Craftsman in January, 1990, p. 104). The car sides in the kit were not modeled with the indentations on the interior which should be present in a panel-side car, so I wanted to make a load which would pretty well fill the car and hide the lack of a correct interior contour, while remaining removable. This is the loose load of dowels in the car:

Girders make an interesting and relatively easy load for gondolas (or flat cars). The old Atlas styrene through-girder bridge is a cheap and easy source of girders, which can also be kitbashed to greater or lesser lengths as desired. I just cut the sides away from the deck and proceed. If they need to be lengthened, I make an overlay strip of 0.005-inch styrene (approximately matching the ones already on the Atlas molding) to cover the joint. I used to impress rivets into such strips with a scriber, but now Archer rivets are a much easier and better-looking alternative (if you don’t already know this product, visit http://www.archertransfers.com/SurfaceDetailsMain.html .

Here is one such lengthened girder, as a load in the Athearn mill gondola. It is sufficiently long that the working end doors of the gondola need to be dropped to accept this load.

Of course, girders like this might be painted in the final color to be used when they were installed as part of a bridge. I represented that in a different girder load, with aluminum paint, and another possibility would be black. Here is my silver girder, with a Jones & Laughlin Steel logo:

The gondola is a reworked E&B Valley model, representing PRR Class G26, with some distressing of the top chord with a heat gun. The girder has a low bracing arrangement which should probably be replaced by something like the bracing in this next project, a short girder.

My shorter girder was built from Atlas bridge remnants, and I have arranged it so it can be loaded on either a gondola or flat car. A girder this size might equally likely be loaded flat, but I have arranged it for loading on edge. Most of the Loading Rules diagrams for such loading are for loads across two or more cars, but they have in common diagonal braces on each side of the load (somewhat as shown above for the long Bethlehem girder), as in this drawing from the 1926 Rules:

I used scale 6 x 6-inch stripwood for the bracing, with a strip of styrene scale 1 x 6-inch for the iron top strap (angled bends like these in styrene strip can be made with care), which I painted medium gray.

You can see in this view that I added flanges with holes for future rivet or bolt assembly on each end of this short girder. When in a gondola (this is a Detail Associates model), this load looks this way:

There are lots more long-load ideas in the Loading Rules books, and they are fun to build as well as fun to operate on the layout.

Tony Thompson

Monday, March 5, 2012

Open-car loads: lumber in gondolas

Lumber loads were very important parts of traffic in the Far West in the 1950s, much directed to building booms in Southern California and in the Bay Area, but much also headed eastward to other destinations. Broadly speaking, in that era there were two categories of lumber shipments: rough lumber, and finished lumber. Finished lumber traveled whenever possible in box cars, with double-door cars preferred for ease of loading and unloading. Rough lumber was typically shipped on flat cars, but perennial shortages of suitable flat cars by several Western railroads led to frequent use of gondolas also. I intend to post later some modeling approaches for flat car loads, but this post today is for gondola loads.

There were AAR Loading Rules for such loads, as there were for practically all categories of open-car loads. As it happens, the rules for lumber were essentially the same for flat cars and gondolas. Here is a Rules diagram from 1926, which shows the basic approach (note that the cross-ties connecting the stakes are drawn as boards):

You can see that the minimum size shown for intermediate strips, called “binders” or “stickers,” is 3 x 7/8-inches, so nominal 1 x 4 lumber would be appropriate. These were required at that time to be spaced at not more than 30-inch intervals, but below the sides of gondola, no strips were required. The minimum number of vertical stakes per pile is three. These are to be tied together at the top with wire or boards.

The Rules stated that two piles, as in the middle sketch above, were preferred to single large piles on a car. It was later suggested that piles also be divided across the car width, in other words that the end view of the car would show two piles; in combination with the side view, this would make four piles per car. There were to be vertical stickers between the width-wise piles. In later years, a requirement was also added for stickers underneath the load, and the vertical spacing of intermediate stickers was increased to 48 inches.

For photos, a useful source is the issue of Railway Prototype Cyclopedia (no. 20) with an article on open-top loads. However, it is only about flat cars. The article also contains a number of reprinted Loading Rules pages, so is valuable for that also.

One advantage to building gondola loads generally is that the side stakes are set in folding stake holders on the inside of the gondola. Those stake holders can’t be seen with the load in place, so it’s not possible to tell if they are spaced correctly, and the modeler is free to space the stakes as convenient. As I will discuss when I post about flat car lumber loads, the situation is entirely different for flat cars.

Here is an illustration of an SP train in Oregon, headed for California in 1948. The head end is all lumber cars, and 22 are visible in this shot (SP photo N-1660-14); it happens that 9 of the 22 are gondolas. (And note that the composite gondola closest to the camera is an L&N USRA car, from their 74000 series. Though SP used its own cars very heavily for lumber traffic, cars of other railroads can certainly be seen in SP lumber trains.)

These loads almost all are in accord with the rule, of three stakes per lumber pile, and most are tied together across the top with wire. Stake heights in this photo are quite variable and in several cases greatly exceed the height of the lumber piles.

My approach to this type of load is much like what I described for gondola loads of pipe, to build up the material without full-length pieces on the bottom, where they are invisible. I sized the load I describe in this post to fit the Red Caboose steel GS gondola, because the interior width of that car is slightly less than the Detail Associates model of the same car, or the width of the Challenger brass cars (of which I have a couple, provided in return for my supplying Challenger with information on the cars–in all candor, I don’t often find brass freight cars worth the investment).