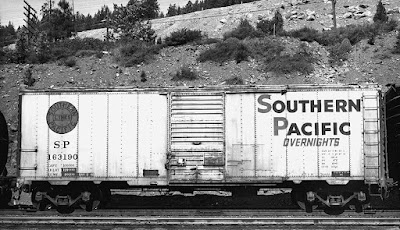

The previous post on this topic took up the challenge, describing what I might typically do to upgrade a car kit to my usual layout standards. The kit is an InterMountain 12-panel box car kit. You can read my preliminary analysis of needed changes and upgrades in that previous post, which is at: https://modelingthesp.blogspot.com/2021/12/improving-freight-car.html .

I should add that before adding the weights, I drilled and tapped the bolster centers for 2-56 truck screws (discard those self-tapping screws!). This makes the screw holes evident inside the car body, and prevents gluing the weights atop them. And since the doors will be glued on, no need to paint the weights.

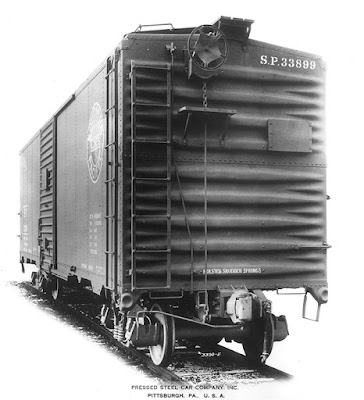

I mentioned in the previous post that the kit side doors were not the correct style, but that I had replacements. Here are the replacements, with the kit placard boards and route card boards in place.

I also mentioned using a Kadee Morton running board to replace the kit’s incorrect board. This has been received. But it isn’t quite the same color as the InterMountain kit parts. So both the running board and the new doors called for a paint match to the IM molded color. Like many modelers, I have a considerable stash of red-brown paint colors, of many brands. The closest match here was Tamiya “Hull Red,” no. XF-9.

The kit coupler boxes are intended to be glued in place, including box covers. I learned long ago that this is a prescription for coupler maintenance problems, so I clipped off the posts on the box covers, drilled a hole centered on the post location, and tapped both box and cover (and car body) for 2-56. This isn’t a great coupler box, and a Kadee box might be better; but I did use the kit box to install Kadee #58 couplers.

Incidentally, one advantage with making the kit coupler boxes removable, and attached with a screw, is that if any problems later develop with these boxes, they would be readily replaced with Kadee boxes.

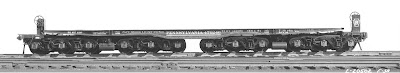

Lastly, in changes to kit parts, I discarded the kit’s molded plastic wheelsets intended for the trucks — this type of wheel has long been banned from my operating equipment — and replaced them with InterMountain Code 88 wheelsets. These metal wheelsets look better, run better, and don’t collect dirt.

I should mention that although these InterMountain trucks resemble the ASF A-3 trucks actually applied to the prototype cars, they are not quite an A-3, but I decided to use them, since they are close. For a great deal more on this point, you may wish to consult Richard Hendrickson’s 2014 article on model trucks (there’s a link at: http://modelingthesp.blogspot.com/2013/07/another-update-to-richard-hendricksons.html ).With these modifications, I was ready to proceed with the more mundane aspects of the kit assembly, most of which I won’t bother to describe, but will then carry out weathering and other finishing details. Those will be described in a future post.

Tony Thompson